Automatic Bundle Loader Fiber Laser Pipe Cutting Machine

Model No.: P2060A / P3080A

Introduction:

- Pipe length : 6000mm / 8000mm

- Pipe diameter : 20mm-200mm / 30mm-300mm

- Loading size : 800mm*800mm*6000mm / 800mm*800mm*8000mm

- Laser power : 1000W 1500W 2000W 2500W 3000W 4000W

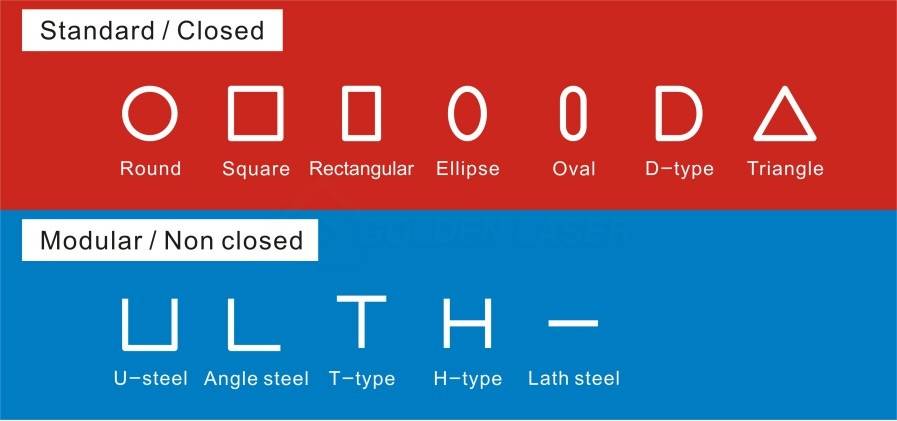

- Applicable tube type : Round tube, square tube, rectangular tube, oval tube, D-type T-shaped H-shaped steel, channel steel, angle steel, etc.

- Applicable materials : Stainless steel, mild steel, galvanized, copper, brass, aluminum, etc.

Auto Bundle Loader Tube Laser Cutting Machine

We are always improving and upgrading the tube laser cutting machine performance.

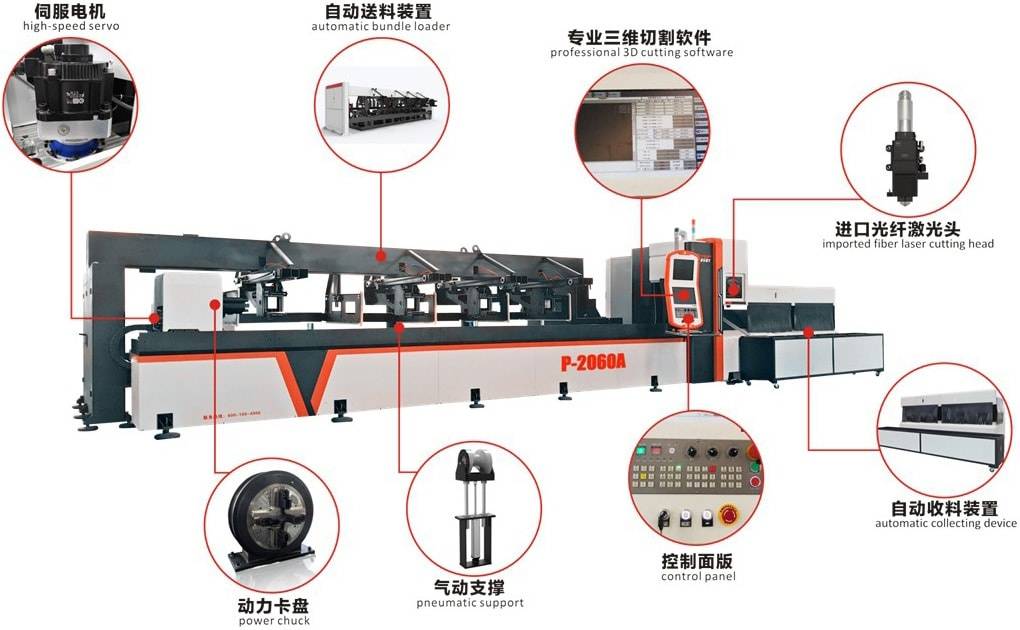

Components

Tube Laser Cutting Machine Details

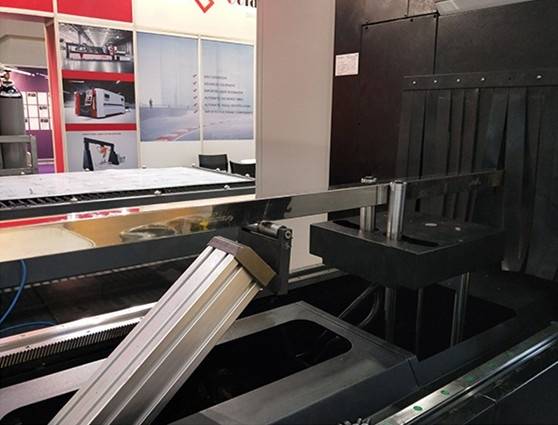

Automatic Bundle Loader

Automatic bundle loader saves labor and loading time, result in mass production purpose.

Round pipe and rectangular pipe can be fully automated loading without human intervention. Other shaped pipe can be semi-automatic feeding manually.

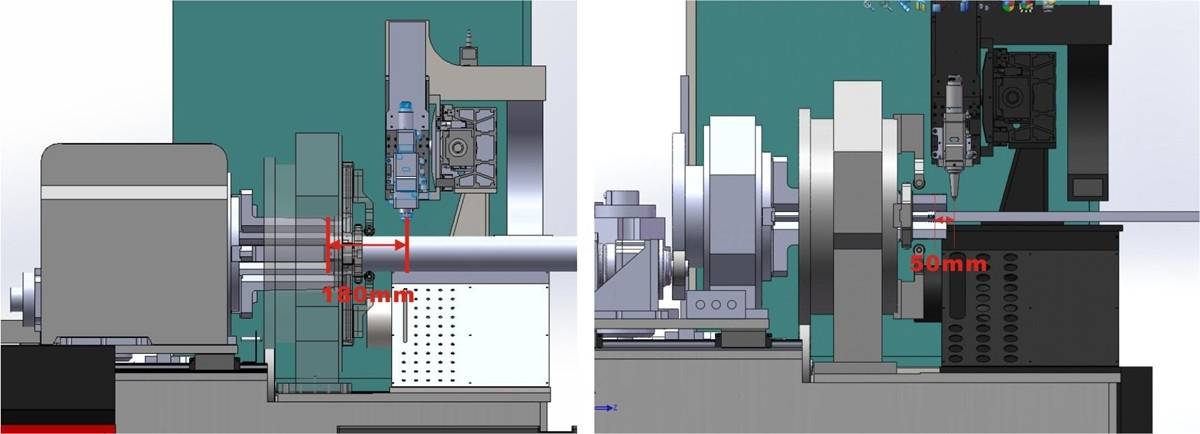

Advanced chuck mounting system

Top material floating support

Floating Support / Collecting Device

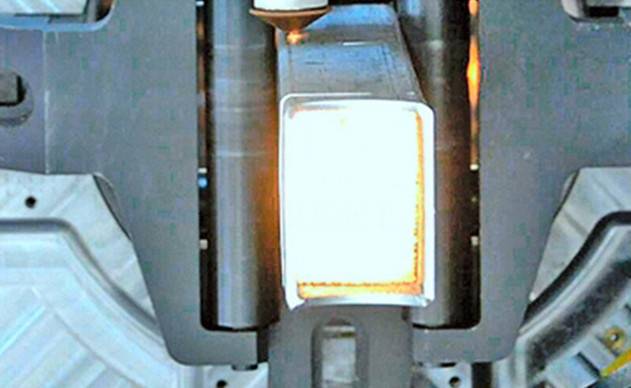

Three-axis linkage

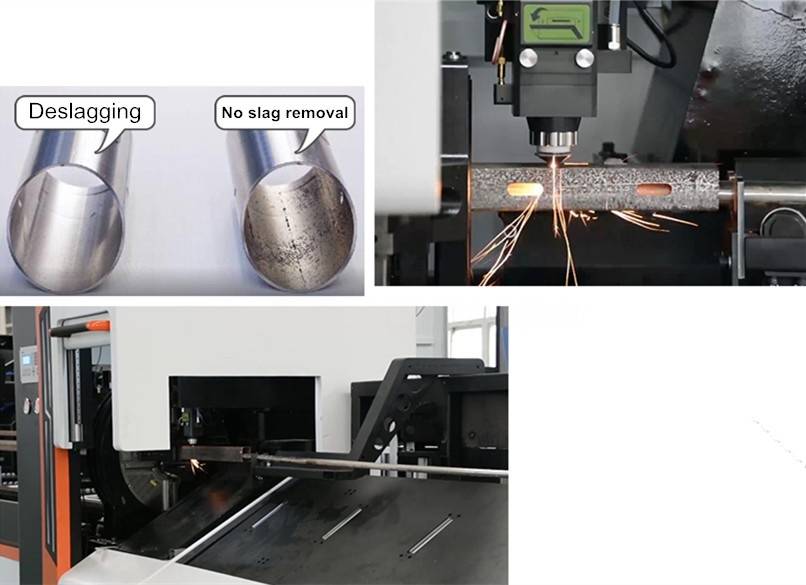

Welding seam recognition

Hardware - wastage

Optional - the third axis cleaning inner wall device

Tube Laser Cutting Samples

Technical Parameters

| Model number | P2060A |

| Laser power | 1000W / 1500W / 2000W / 2500W / 3000W / 4000W |

| Laser source | IPG / nLight fiber laser resonator |

| Tube length | 6000mm |

| Tube diameter | 20mm~200mm |

| Tube type | Round, square, rectangular, oval, OB-type, C-type, D-type, triangle, etc. (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc. (option) |

| Repeat position accuracy | ± 0.03mm |

| Position accuracy | ± 0.05mm |

| Position speed | Max. 90m/min |

| Chuck rotate speed | Max. 105r/min |

| Acceleration | 1.2g |

| Graphic format | Solidworks, Pro/e, UG, IGS |

| Bundle size | 800mm*800mm*6000mm |

| Bundle weight | Max 2500kg |

GOLDEN LASER – FIBER LASER CUTTING SYSTEMS SERIES

|

Model NO. |

P2060A |

P3080A |

|

Pipe Length |

6m |

8m |

|

Pipe Diameter |

20mm-200mm |

20mm-300mm |

|

Laser Power |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

|

|

Model NO. |

P2060 |

P3080 |

|

Pipe Length |

6m |

8m |

|

Pipe Diameter |

20mm-200mm |

20mm-300mm |

|

Laser Power |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

|

|

Model NO. |

P30120 |

|

Pipe Length |

12mm |

|

Pipe Diameter |

30mm-300mm |

|

Laser Power |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-1530 |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W |

1500mm×3000mm |

|

GF-1560 |

1500mm×6000mm |

|

|

GF-2040 |

2000mm×4000mm |

|

|

GF-2060 |

2000mm×6000mm |

|

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-6060 |

700W / 1000W / 1200W / 1500W |

600mm×600mm |

Application Industry

Mainly used in fitness equipment, office furniture, shelves, steel structure, medical industry, rail rack and other industries for round pipe, square tube, rectangular tube and shaped pipe and other profile processing.

Applicable Materials

Stainless steel, carbon steel, aluminum, brass, copper, galvanized steel, alloy steel.

Applicable Types of Tubes

Tube Laser Cutting Machine for Mass Production in our Customer Site

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable tube laser cutting machine.

1, What type of tube do you need to laser cut? Round tube, square tube, rectangular tube, oval tube or other shaped tube?

2. What kind of metal is it? Mild steel or stainless steel or aluminum or..?

3. What is the wall thickness, diameter and length of the tube?

4. What is the finished product of the tube? (What is the application industry?)

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?