- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

Ballistic Fabrics Laser Cutter for Aramid, UHMWPE, Kevlar, Cordura

Model No.: JMC SERIES

Introduction:

- Gear and rack drives provide high acceleration and minimize maintenance

- World-class CO2 laser source

- Vacuum Conveyor System

- Automatic feeder with tension correction

- Japanese Yaskawa servo motor

- Control system specially tailored for laser processing of industrial fabrics

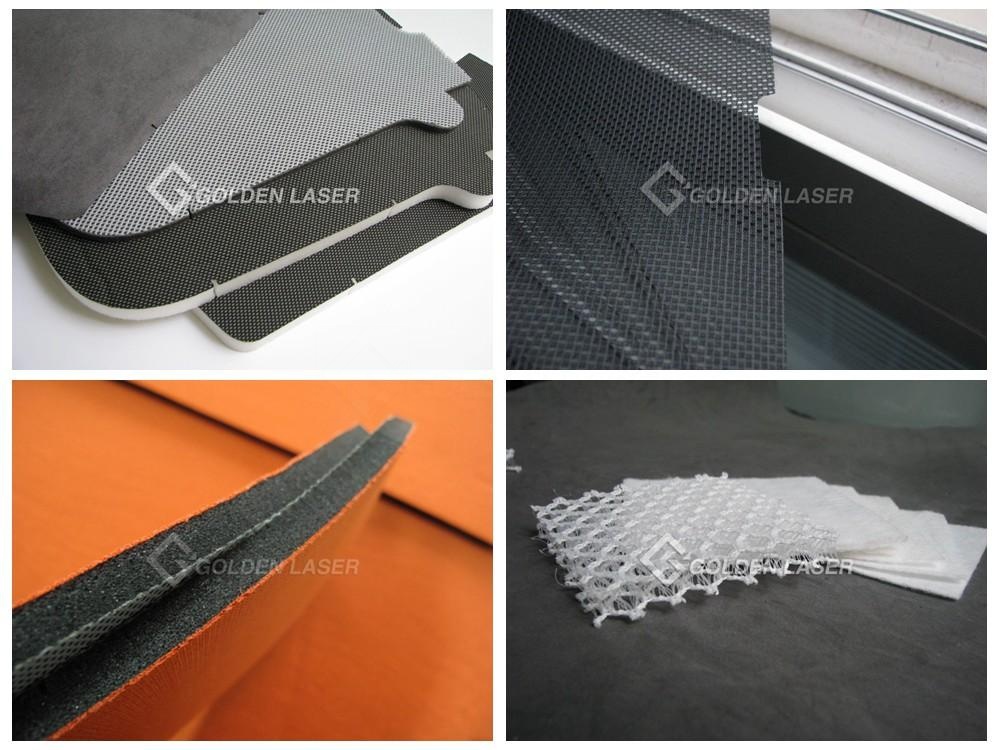

Goldenlaser offers CO2 laser cutting system especially developed for cutting protective textiles such as Ultra High Molecular Weight Polyethylene Fiber (UHMWPE), Kevlar and Aramid Fibres.

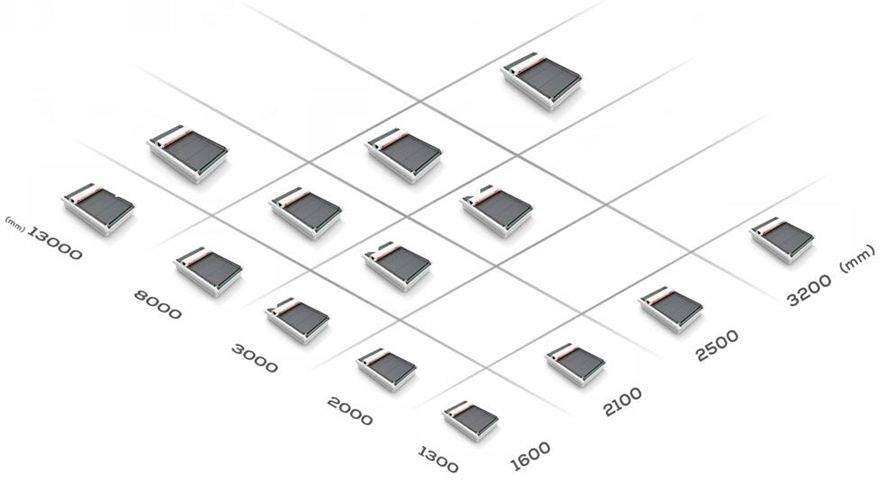

Our CO2 laser cutting machine executes cut plans with high precision, speed and reliability, and robust flatbed cutting table featuring a variety of sizes.

Both single and dual laser heads are available.

This laser machine is perfect for continuous textiles cutting on the roll thanks to the automatic conveyor system.

Our lasers can be fitted with CO2 DC glass tubes and CO2 RF metal tubes like Synrad or Rofin as per request.

There are many options available. And we can customize the laser machine to pretty much any configuration to fulfill your specific production demand.

Properties of the CO2 Laser Cutting Machine

JMC SERIES HIGH-PRECISION HIGH-SPEED LASER CUTTING MACHINE PERFECTION IN DETAILS

1. High-speed cutting

High-precision grade gear and rack double drive system, with high-power CO2 laser tube equipped. Cutting speed up to 1200mm/s, acceleration 8000mm/s2, and can maintain long-term stability.

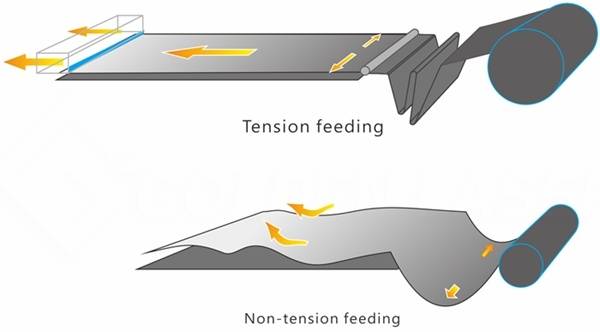

2. Precision tension feeding

No tension feeder will easy to distort the variant in the feeding process, resulting the ordinary correction function multiplier.

Tension feeder in a comprehensive fixed on both sides of the material at the same time, with automatically pull the cloth delivery by roller, all process with tension, it will be perfect correction and feeding precision.

3. Automatic sorting system

- Fully automatic sorting system. Make the feeding, cutting and sorting of materials at one go.

- Increase the processing quality. Automated unloading of the completed cut parts.

- Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

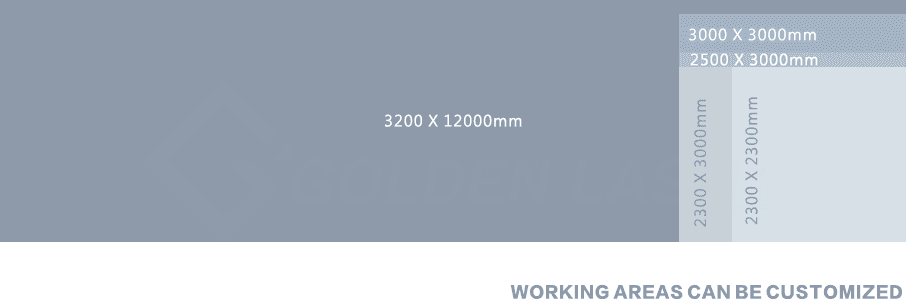

4. Working table sizes can be customized

2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), Or optional. The largest working area is up to 3200mm×12000mm (126in×472.4in)

Optimize your workflow with the options:

CUSTOMIZED OPTIONAL EXTRAS SIMPLIFY YOUR PRODUCTION AND INCREASE YOUR POSSIBILITIES

Makes the processing safer and reduces fume and dust that may be generated during processing.

Allows the installation of a roll of fabric. It feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime to achieve the maximum productivity possible.

Helps as a reference to check where the laser beam will land on to your material by tracing a simulation of your design without activating the laser.

Automatic camera detection enables printed materials to be cut out precisely along the printed outline.

Marking of different cuts, e.g. with sewing markings, or for the tracking of subsequent process steps in production with the options Ink Printer Module and Ink Marker Module.

To maximize the production of the laser cutter, JMC Series laser conveyor machines have an option for dual lasers which will allow for two parts to be cut simultaneously.

For laser engraving and perforation with unmatched flexibility, speed and accuracy.