Laser Cutting Foam: Benefits and Applications

Foam is a common material that is used in many industries and has many different applications. It can be found in furniture, automotive, insulation, construction, packaging and more. Lasers are increasingly being used in manufacturing processes because of their precision and ability to cut through materials quickly. One material that is popular for laser cutting is foam. Cutting foam with laser offers numerous benefits over traditional methods. In this article, we will discuss how lasers work with foam, why you should consider using them instead of traditional methods like scissors or knives, and some common applications where they are best suited for laser cutting foam.

Table of Contents

Is laser suitable for cutting foam?

The answer to this question is a resounding yes!

There are many different types of foam, but they can generally be divided into two categories: closed-cell and open-cell. Closed-cell foam is denser and more waterproof than open-cell foam. Open-cell foam is less dense, absorbs water, and is easier to cut. Some common types of foam include polyester (PES) foam, polystyrene (PS) foam , polyurethane (PUR) foam, polyethylene (PE), and EVA foam. In fact, CO2 laser cutting is an excellent way to cut these foams.

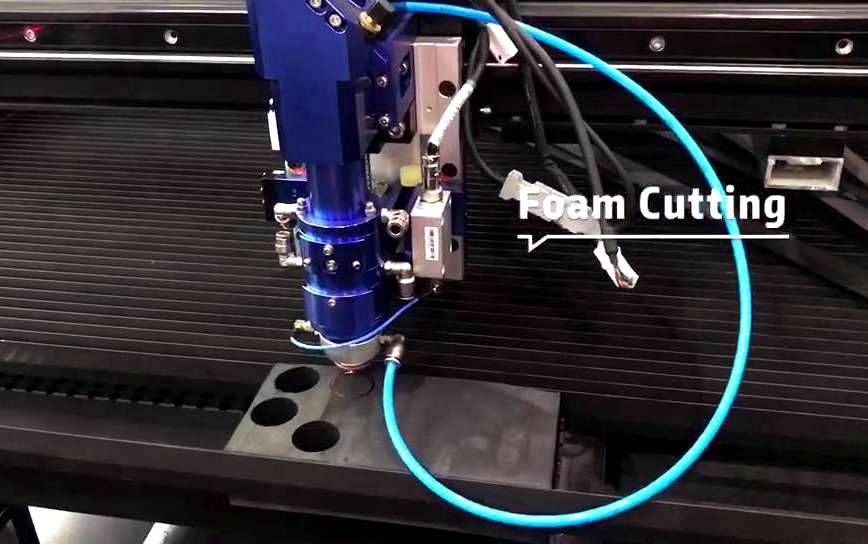

Foam can be cut with lasers in a variety of ways, depending on the type and thickness of the foam material. The most common way to cut foam is by using a laser cutter or engraver which will produce a smooth edge. Lasers can also be used to create intricate designs in foam materials, making them ideal for use in a wide range of industries.

However, there are some applications of foam which cannot be fulfilled by traditional cutting methods like milling or water jetting and these require more advanced techniques - laser cutting. This is due to the fact that lasers produce extremely precise cuts which have minimal waste material near the edges of their cut lines, whereas waterjet cuts have less precision, resulting in rougher edges.

Why should businesses consider using laser to cut foam?

There are many reasons why businesses should consider using laser to cut foam in their next project:

Precision

Laser is precise by design - it can cut straight lines, curves and even complex shapes without distortion of the material being cut. This makes it a perfect tool for cutting foam, which often has irregular shapes and sizes. Foam cutting with laser is more accurate than traditional methods, making it a popular choice for many businesses.

Speed

Laser cutting can be completed much quicker than traditional methods. It also allows you to work with larger pieces of material without slowing down production. laser cutting makes it the perfect choice for businesses looking to produce high-quality products quickly and efficiently.

Efficiency

Foam can be cut with laser in any shape or size, so it is easy to customize for your specific needs. In addition, there is no need to waste time and material by cutting it into smaller pieces that may not be needed. This also reduces the amount of scrap that needs to be disposed, making it more environmentally friendly.

Cost effective

With no need for expensive tooling and a quick turnaround time, laser cutting is one of the most cost-effective methods for foam cutting. laser cutting saves businesses time and money, as well as reduces the amount of material used in production. It also allows you to reduce waste by using leftover scraps for other projects or materials like insulation.

Minimize waste

Laser cutting allows you to minimize waste while achieving precise results quicker and more accurately than traditional approaches, like milling or water jetting. This reduces the amount of material used in production which lowers costs and minimizes your carbon footprint. It can also improve working conditions with less fumes producing a safer work environment for employees.

Clean process

Laser cutting is also a clean process - there is very little waste produced and no harmful fumes. The cuts are precise and the edges are smooth, so there is no need for additional finishing steps. This makes laser foam cutting an attractive option for many businesses.

Laser cutting is a non-contact process, so there's no damage to the surrounding material. It also produces very little heat and almost no waste, which makes it an environmentally friendly option. Additionally, laser foam cutting can be done quickly and easily with minimal setup time required. This makes it a cost-effective solution for businesses of all sizes.

What are the typical application industries of laser cutting foam?

Foam is a very versatile material and has many uses in both industrial and consumer applications. Some examples include automotive, filters, furniture, packaging, footwear and sign making. Foam is often used in these industries to create prototypes or finished products. It is a lightweight material that can be easily cut and shaped, making it a popular choice for a variety of applications. In addition, foam is an insulator, which means it can help keep products cool or warm depending on the needs of the customer. This makes it an ideal material for a wide range of products.

Laser-cut foam for automotive interiors

The automotive industry is a key market for foam applications. Automotive interiors are one of the most visible areas where foam can be used to improve comfort, appearance and safety. In addition, sound absorption and insulation are also important factors in automobiles. Foam can play an important role in all of these areas. For example, polyurethane foam can be used to line the door panels and roof of a car to improve sound absorption. It can also be used in the seating area to provide comfort and support. In addition, polyurethane foam is an effective insulator, which can help keep the interior of a car cool in summer and warm in winter.

In the field of car seats padding, foam is often used to provide comfort and support. Foam can also be cut with a laser to create specific shapes for a custom fit. Lasers are precise and efficient, making them an ideal choice for this application. Additionally, by using a laser to cut the foam, there is little waste generated from the process which helps to keep costs down.

Laser-cut foam for filters

Laser-cut foam is often used in the filtration industry as it has a number of benefits over other materials. It is highly porous, which allows for excellent air flow and makes it an ideal filter media. Foam filters are also very effective at trapping moisture, which makes them a good choice for use in humid environments. In addition, laser-cut foam is non-reactive and does not release harmful particles into the air like other filter media does. This makes it a safe and environmentally friendly choice for filtration applications. Finally, laser-cut foam is relatively inexpensive and easy to manufacture, making it an economical option for many filter applications.

Laser-cut foam for furniture

Laser-cut foam is commonly used in the furniture industry to create intricate and delicate designs. The high precision of laser cutting allows for very precise cuts, which can be difficult or impossible to achieve with other methods. This makes it a popular choice for furniture manufacturers who want to create unique and eye-catching pieces. In addition, laser-cut foam is often used as a cushioning material, providing comfort and support for furniture users.

Creating customised foam furniture is now possible with laser cutting. This has become a popular trend in the home decor industry as well as for businesses like restaurants, hotels and more. From seat cushions to table tops, there are many options available when it comes to creating your own pieces of unique furniture.

An example customer we worked with was interested in creating custom sofa cushions out of laser cut polyurethane foam rather than traditional upholstery fabric. Using our CO2 laser cutter, they can create the exact shape and size they want for each cushion, then cut them out quickly and easily. The final product turned out fantastic and was very well-received by their customers!

Laser-cut foam for packaging

Foam is often used in packaging to protect products during shipping. It is lightweight and can be easily cut into custom shapes, making it the perfect material for many types of packages. Laser cutting is a quick and efficient way to create foam packaging that will protect your product during transport.

Laser-cut foam for footwear

Laser cut foam is commonly used in the footwear industry to create shoe soles. The laser-cut foam is durable and shock absorbent, making it a perfect material for shoe soles. Additionally, the laser-cut foam can be designed to have specific cushioning properties, depending on the needs of the customer. This makes it an ideal material for shoes that need to provide extra comfort or support. Thanks to its many benefits, laser-cut foam is quickly becoming a popular choice for shoe manufacturers worldwide.

Laser-cut foam for construction

In the construction industry, foam is often used as insulation. It's a lightweight and effective way to keep homes and businesses warm in the winter and cool in the summer. Laser cutting can be used to create custom-sized pieces of foam insulation that will fit perfectly in any space.

Things to consider when choosing a laser cutter for foam?

- Material type of the foam you intend to cut.

- The maximum size and thickness of the foam you need to cut.

- The power and speed of the laser cutter.

- What software is available to support your cutting needs?

- How experienced are you with using a laser cutter?

- Do you have access to technical support if needed?

- Your budget and what features are most important to you.

- Do you need a large format laser or do you have space limitations?

There are a few considerations that need to be addressed when using lasers for cutting foam, however. The first is heat dissipation. Laser processes create high energy beams of light and in order to get all of it out on one pass through the material, cooling systems must be used so that there is no damage to the foam. Additionally, fumes and gases can be released from the material so an appropriate ventilation system should be in place.

Conclusion

If you’ve been looking for a machine that can cut foam quickly and precisely, we have the solution. Lasers are increasingly being used in manufacturing processes because of their precision and ability to cut through materials quickly. One material that is popular for laser cutting is foam. Cutting foam with laser offers numerous benefits over traditional methods such as faster production times, less waste due to fewer scraps left behind from old-fashioned saws, and lower energy costs thanks to lasers' low power consumption rates. So if you want your company to continue growing while also saving time and money on equipment needs, just Contact Us Today!