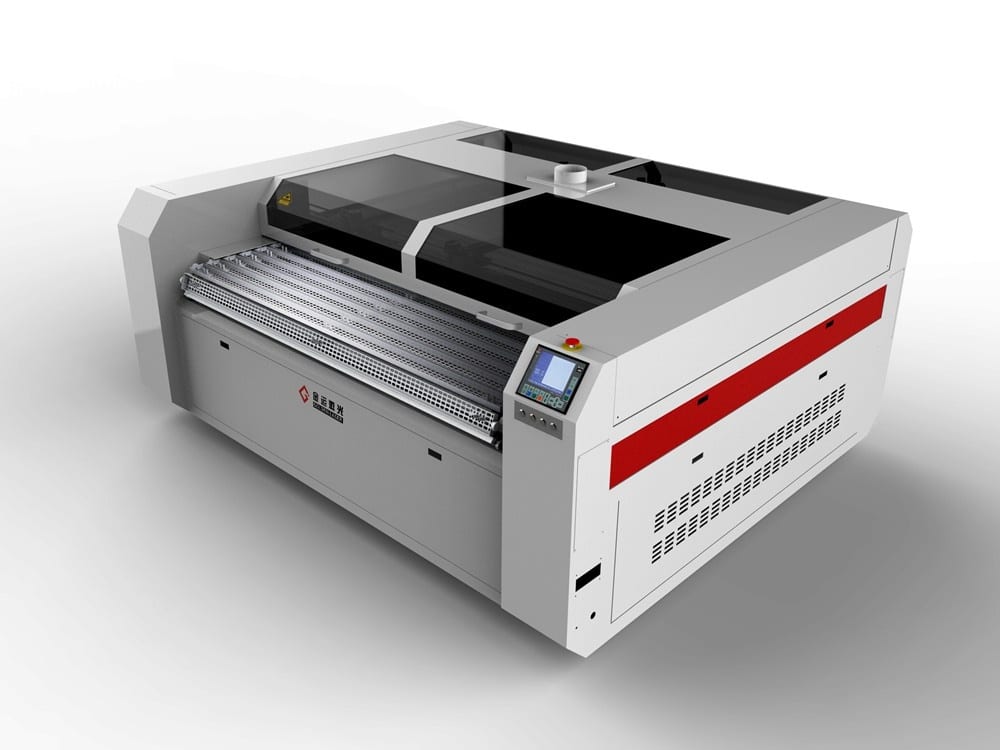

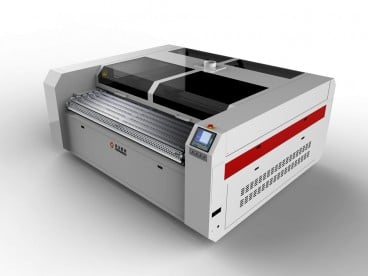

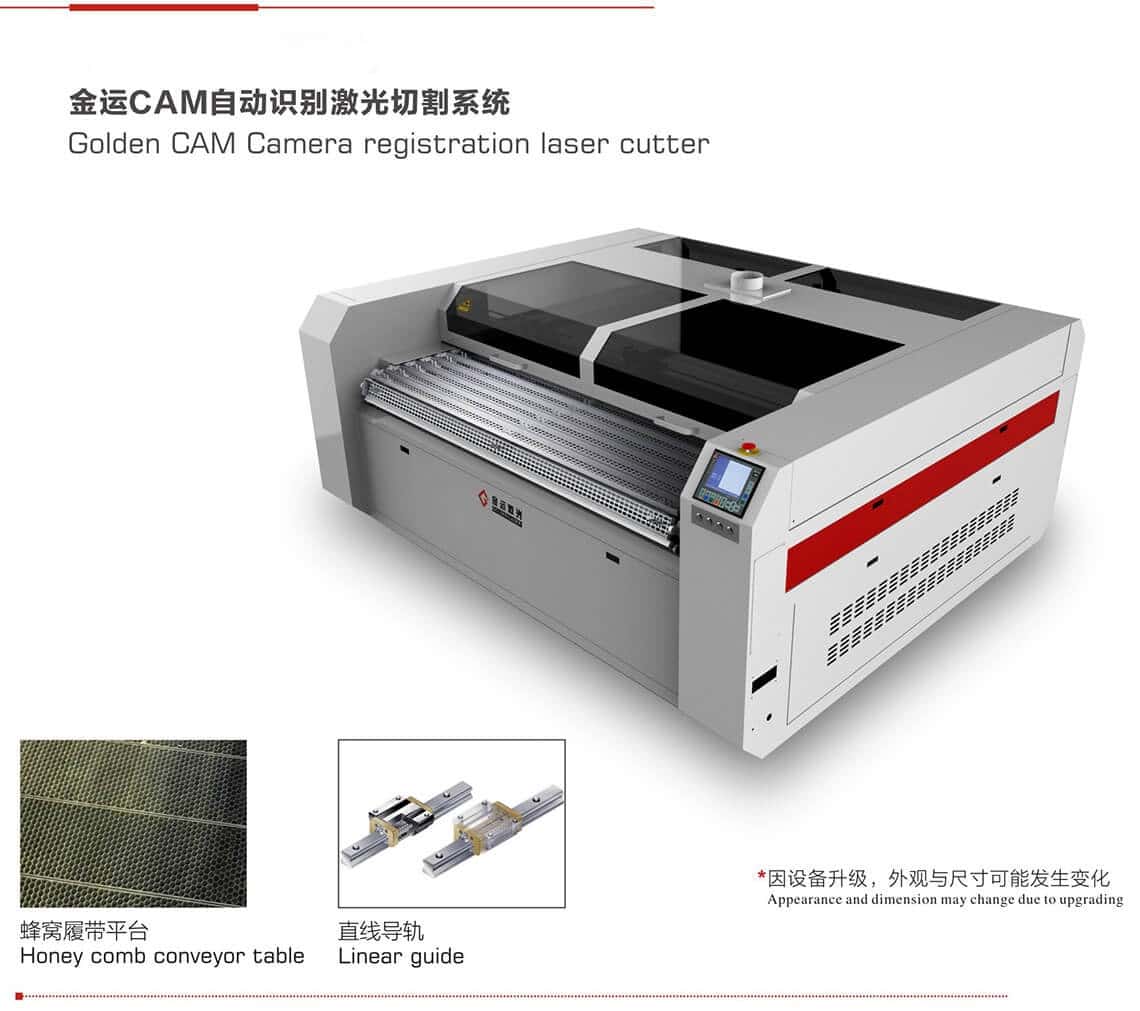

GoldenCAM Camera Registration Laser Cutter

Model No.: MZDJG-160100LD

Introduction:

Numbers, letters, and logos are easily deformed during sublimation printing. GoldenCAM high precision vision recognition system, with high precision registration marks positioning and intelligent deformation compensation algorithm provided by the software to complete the precision cutting of various high-demand dye sublimation printed products.

- Working Area : 1600mm×1000mm / 62.9"×39.3"

- Recognition Mode : CCD camera recognition

- Working Table : Honey comb conveyor working table

- Laser Power : 70W / 100W / 150W

GoldenCAM Camera Recognition System

The most popular printing technology for textile is dye sublimation printing. The result of sublimation is a nearly permanent, high resolution, full color print, and the prints will not crack, fade or peel. While there will be distort and stretch of the materials when it is dye sublimated. It means the shapes will change after sublimation printing. How can we get a precise shape as you want? It not only requires the recognition system is high precision, but also requires software has the function to amend the distorted shapes. This is especially important for making small logo, numbers, letters and other precise items.

GoldenCAM camera recognition technology will help you solve this problem. The camera is installed next to the laser head; the fiducially marks are printed around the printing shapes; the CCD camera will detect marks for positioning. After the camera detects all the marks, the software will adjust the original shapes according to the distortion material; it ensures the high precision cutting result.

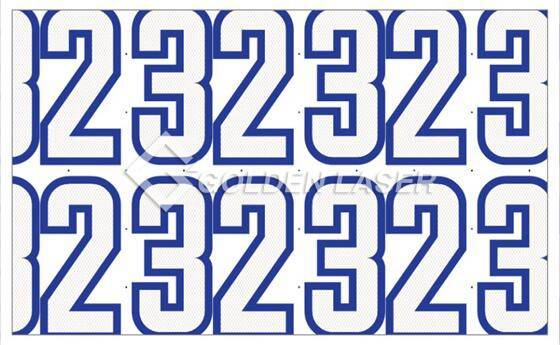

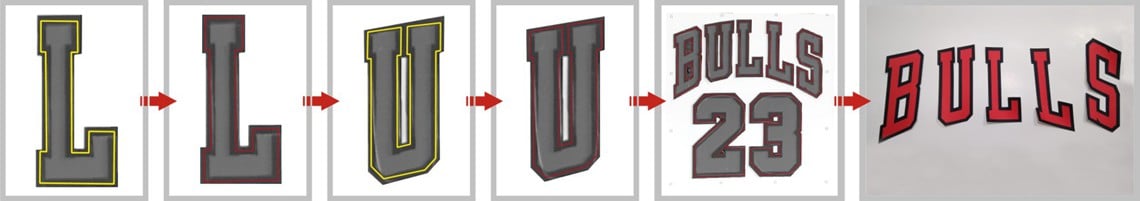

How to Make Digital Printed Numbers / Logos / Letters?

1. Print the graphics with marks on the paper.

1. Print the graphics with marks on the paper.

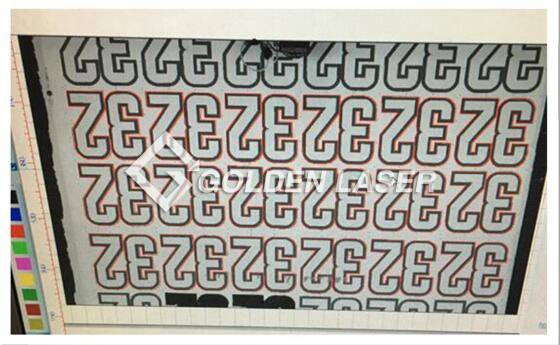

2. Dye sublimation the graphics to the fabric.

2. Dye sublimation the graphics to the fabric.

3. GoldenCAM camera recognition laser system detects the marks and the software handle the distortion.

3. GoldenCAM camera recognition laser system detects the marks and the software handle the distortion.

4. Laser cutting accurately after the software handles the distortion.

4. Laser cutting accurately after the software handles the distortion.

GoldenCAM Camera Recognition Laser Cutter

Model No.: MZDJG-160100LD

Machine Features

High-speed linear guide, high-speed servo drive

Cutting speed: 0~1,000 mm/s

Acceleration speed: 0~10,000 mm/s

Precision: 0.3mm~0.5mm

Traditional camera recognition methods

There are three main types of traditional camera recognition:

→ Registration marks recognition (only 3 marks);

→ Whole template recognition;

→ Special features recognition.

The traditional camera recognition method has a lot of limitations, such as slow acceleration, poor accuracy, and unable to correct distortions.

How GoldenCAM Camera Recognition System Works?

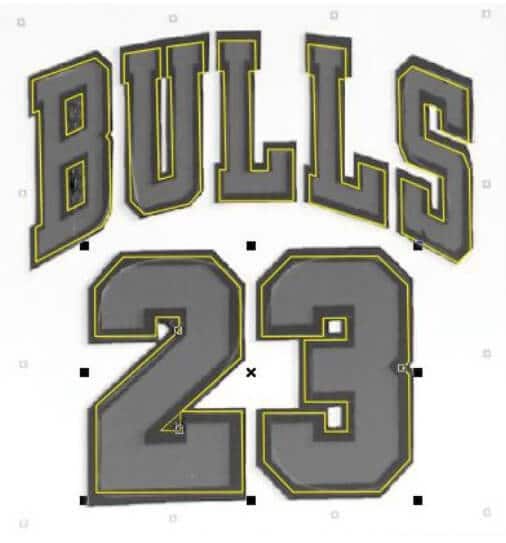

The yellow line is the cutting path of the original design, and the black contour is the actual print contour with distortion during sublimation. If cut according to the original graphics, the finished product will be defective. How to cut out the precise shape?

Software for deformation compensation and correction. The red line represents the path after the software compensates for the deformation. Laser machine cuts accurately along the corrected pattern.

Precision laser cutting - registration marks identification

Application

Dye-sublimation printed small logo, letter, number and other precision items.

Watch GoldenCAM Camera Laser Cutter in Action!

Technical Parameters of the Camera Laser Cutter

| Working Area | 1600mm×1000mm / 62.9″×39.3″ |

| Recognition Mode | CCD camera recognition |

| Working Table | Honey comb conveyor working table |

| Laser Power | 70W / 100W / 150W |

| Laser Tube | CO2 glass laser tube / CO2 RF metal laser tube |

| Control System | Servo motor system |

| Cooling System | Constant temperature water chiller |

| Exhaust System | 1.1KW exhaust fan×2, 550W exhaust fan×1 |

| Power Supply | 220V, 50Hz or 60Hz / single phase |

| Electrical Standard | CE / FDA / CSA |

| Power Consumption | 9KW |

| Software | GOLDENLASER CAM software |

| Space Occupation | 3210mm(L ) × 2560mm(W) × 1400mm(H) / 10.5’ × 8.4’ × 4.6’ |

| Other Options | Auto feeder, red dot positioning |

GOLDENLASER Full Range of Vision Camera Laser Cutting Systems

Ⅰ High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1300mm (63”×51”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

Ⅱ High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ⅲ Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Ⅳ Smart Vision (Dual Head) Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

Ⅴ CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

Typical Application

Dye sublimation printed logos, numbers, letters, , tackle twill logos, numbers, letters, patches, Symbols, crests, etc.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?