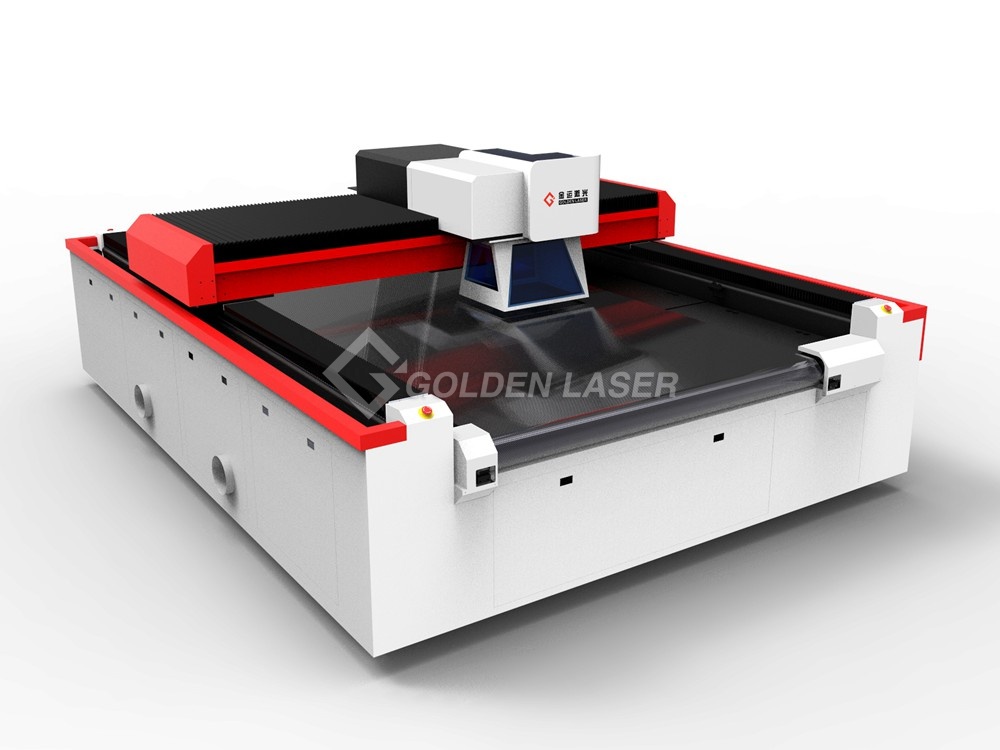

CO2 Galvo Laser Machine with Conveyor for Engraving Cutting

Model No.: JMCZJ(3D)160100LD

Introduction:

- 3D dynamic Galvo laser system

- One time processing area 450×450mm

- Capable of seamless splicing up to 1600mm

- Roll to roll capability

CONFIGURATION

| Laser type | Co2 RF metal laser tube |

| Laser power | 150W / 300W / 600W |

| Working area | 1600mm × 1000mm (63” × 39.3”) |

| Working table | Conveyor working table |

| Motion system | Offline servo system, 5 inches LCD screen display |

| Cooling system | Constant temperature water chiller |

| Power supply | AC220V ± 5% / 50Hz |

| Format supported | AI, BMP, PLT, DXF, DST, etc. |

| Options | Auto feeding system |

Other bed sizes are available.

E.g. Model JMCZJ(3D)170200LD, working area is 1700mm × 2000mm (66.9" × 78.7")

APPLIED RANGE

Applicable Materials:

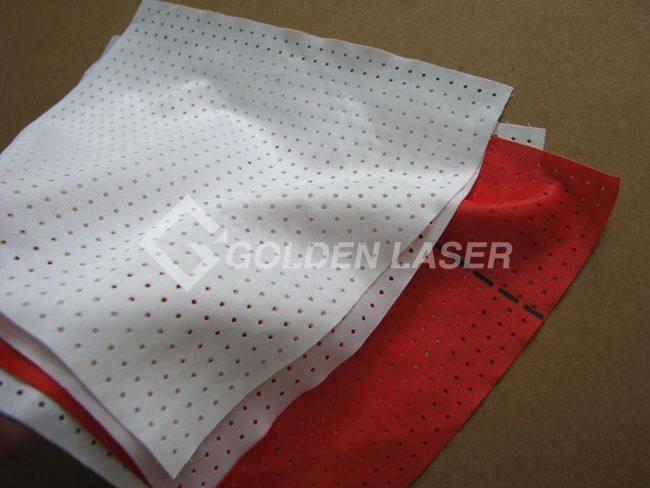

Suits for but not limited to textiles, synthetic fabric, lightweight fabric, stretch fabric, technical textile, leather, EVA foam and other non-metal materials.

Applicable Industries:

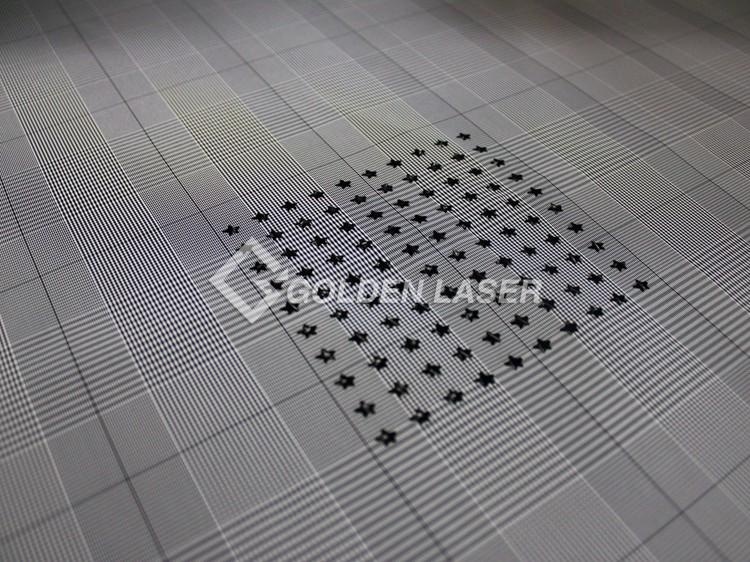

Sportswear - active wear perforating; jersey perforating, etching, cutting, kiss cutting;

Fashion - apparel, jacket, denim, bags, etc.

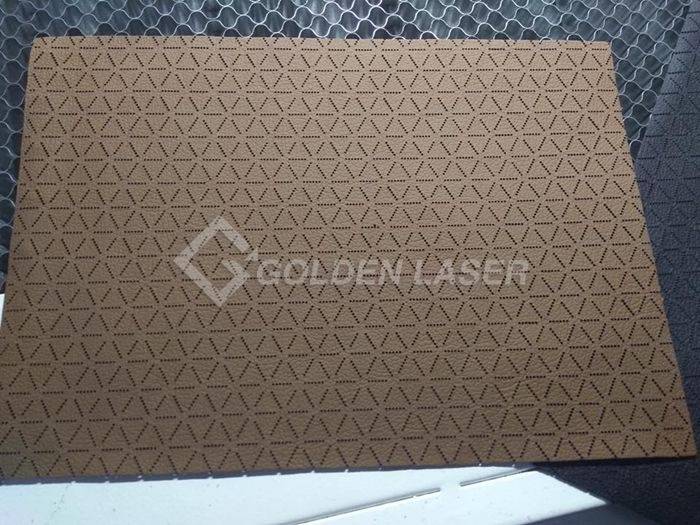

Footwear - shoe upper and insoles engraving, perforation, cutting, etc.

Interiors - carpet, mat, sofa, curtain, home textile, etc.

Technical textiles - automotive, airbags, filters, air dispersion ducts, etc.

JMCZJ(3D)160100LD Galvanometer Laser Machine Technical Parameters

| Laser type | Co2 RF metal laser tube |

| Laser power | 150W / 300W / 600W |

| Working area | 1600mm × 1000mm (63” × 39.3”) |

| Working table | Conveyor working table |

| Motion system | Offline servo system, 5 inches LCD screen display |

| Cooling system | Constant temperature water chiller |

| Power supply | AC220V ± 5% / 50Hz |

| Format supported | AI, BMP, PLT, DXF, DST, etc. |

| Options | Auto feeding system |

※ Working areas can be customized as per requirement.

Goldenlaser Typical Models of CO2 Galvo Laser Machines

| Gantry & Galvo Integrated Laser Machine (Conveyor working table) | |

| JMCZJJG(3D)170200LD | Working area : 1700mm × 2000mm (66.9″ × 78.7″) |

| JMCZJJG(3D)160100LD | Working area : 1600mm × 1000mm (63” × 39.3”) |

| Galvo Laser Machine (Conveyor working table) | |

| JMCZJ(3D)170200LD | Working area : 1700mm × 2000mm (66.9″ × 78.7″) |

| JMCZJ(3D)160100LD | Working area : 1600mm × 1000mm (63” × 39.3”) |

| Galvo Laser Engraving Machine | |

| ZJ(3D)-9045TB (Shuttle working table) | Working area: 900mm × 450mm (35.4″ × 17.7″) |

| ZJ(3D)-6060 (Static working table) | Working area: 600mm × 600mm (23.6″ ×23.6 “) |

Applicable Materials:

Suits for but not limited to

Textiles, synthetic fabric, lightweight fabric, stretch fabric, technical textile, leather, EVA foam and other non-metal materials.

Applicable Industries:

Sportswear - active wear perforating; jersey perforating, etching, cutting, kiss cutting;

Fashion - apparel, jacket, denim, bags, etc.

Footwear - shoe upper and insoles engraving, perforation, cutting, etc.

Interiors - carpet, mat, sofa, curtain, home textile, etc.

Technical textiles - automotive, airbags, filters, air dispersion ducts, etc.

Please contact GOLDEN LASER for more infomation. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?