CO2 Laser Cutter for Woven Heat Shrinking Protection Sleeve

Model No.: JMCCJG-160200LD

Introduction:

Laser cutter especially for woven heat shrinking protection sleeve made of PET (polyester) warp fibres and shrinking polyolefin fibres. No fraying of the cutting edges due to modern laser cutting.

Laser Cutter for Woven Heat Shrinking Protection Sleeve

Model No.: JMCCJG160200LD

Cutting area: 1600mm×2000mm (63″×79″)

The cutting area can be also customized according to different applications.

This laser cutting machine can cut various of shapes from a single roll (width≤ 63″), also available to cross cut 5 rolls of narrow webs at a time (for example, single narrow web width=12″). The whole cutting is continuous processing (Behind the laser machine there is a tension feeder keeps feeding fabrics into the cutting area automatically).

Key advantages of the laser cutting machine

- Superior cutting quality: clean cut edges, automatic sealed edges, no fraying

- One tool to cut all shapes, no tool wear

- Accurate shapes from laser non-contact cutting and precise mechanism movement

- High precision, high speed, less mechanism maintenance required. World-class CO2 RF laser tube selected (400~600W laser power, according to our experience in technical textiles cutting), dual gear and rack motion system, dual servo motor driving system

Clean and perfect laser cutting results

Technical Parameter

| Laser type | CO2 RF laser tube |

| Laser power | 150W / 300W / 600W |

| Cutting area | 1600mmx2000mm (63″x79″) |

| Cutting table | Conveyor working table |

| Cutting speed | 0-1200mm/s |

| Accelerated speed | 8000mm/s2 |

| Repeating location | ≤0.05mm |

| Motion system | Offline mode servo motor motion system,High precision gear rack drive |

| Power supply | AC220V±5%/50Hz |

| Format support | AI, BMP, PLT, DXF, DST |

| Certification | ROHS, CE, FDA |

| Standard collocation | 3 sets 3000W exhaust fans, mini air compressor |

| Optional collocation | Auto feeding system, red light position, marker pen, 3D Galvo, double heads |

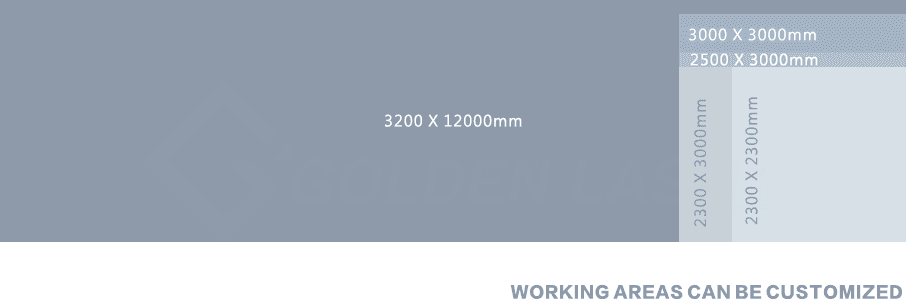

JMC SERIES LASER CUTTING MACHINES

→ JMC-230230LD. Working Area 2300mmX2300mm (90.5 inch×90.5 inch) Laser Power: 150W / 275W / 400W / 600W CO2 RF Laser

→ JMC-250300LD. Working Area 2500mm×3000mm (98.4 inch×118 inch) Laser Power: 150W / 275W / 400W / 600W CO2 RF Laser

→ JMC-300300LD. Working Area 3000mmX3000mm (118 inch×118 inch) Laser Power: 150W / 275W / 400W / 600W CO2 RF Laser

… …

What materials of technical textiles are suitable for laser cutting?

Polyester, polyamide, polyetheretherketone (PEEK), Polyphenylenesulphide (PPS), aramid, aramid fibres, fiberglass, etc.

Application Industry

Cable protection, cable bundling, electric conduction protection and heat protection, mechanical protection, Electrical insulation, Engine compartment, EGR area, rail vehicles, catalytic converter area, automotive, aerospace, military marine, etc.

Laser Cutting Protection Sleeve – Sample Pictures

Please contact GOLDEN LASER for more infomation. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?