Single Head / Double Head Laser Cutter with Conveyor Belt

Model No.: MJG-160100LD / MJGHY-160100LDII

Introduction:

The CO2 laser cutter has a 1600mm x 1000mm (63″ x 39″) work area and accommodates roll materials up to 1600mm (63”) wide. This machine features a conveyor bed that is synchronized with the powered roll feeder in order to bring your material forward as needed. Although designed for roll materials, this laser machine is versatile enough to laser cut flat materials in sheet.

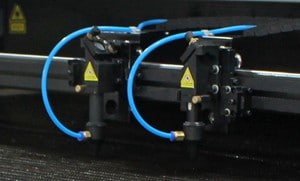

Dual Laser Heads

To maximize the production of your laser cutter, MARS Series Laser conveyor machines have an option for dual lasers which will allow for two parts to be cut simultaneously.

Conveyor Belts

The conveyor bed automatically feeds material forward as needed. Various types of conveyor belts (stainless steel mesh belt, flat flex belt and iron wire mesh belt) are available.

Work Area Options

MARS Series Laser Machines come in a variety of table sizes, ranging from 1400mmx900mm, 1600mmx1000mm to 1800mmx1000mm

Available Wattages

CO2 Lasers Tubes with 80 Watts, 110 Watts, 130 Watts or 150 Watts.

Quick Specifications

Main Technical Parameter of MARS Series Conveyor Belt CO2 Laser Cutter

| Laser Type | CO2 DC glass laser tube |

| Laser Power | 80W / 110W / 130W / 150W |

| Working Area | 1600mmx1000mm (62.9” x 39.3”) |

| Working Table | Conveyor working table |

| Motion System | Step motor / Servo motor |

| Positioning Accuracy | ±0.1mm |

| Power Supply | AC220V ± 5% 50/60Hz |

| Graphic Format Supported | AI, BMP, PLT, DXF, DST |

Available Options

Increase productivity - While the laser machine is cutting, the operator can remove the finished work pieces from the unloading table.

Automatic material feed directly from the roll. Automatic correction function of the feeding unit ensures a constant material alignment.

Preview the engraving or cutting position on the material.

CCD camera detection enables embroidered, woven or printed materials to be cut out precisely along the outline.

Using projection technology for positioning and cutting.

Highlights of MARS Series CO2 Laser Cutter

Goldenlaser patented dual head laser control technology can not only ensure the uniform energy configuration of each laser head, but also automatically adjust the distance between two laser heads according to the width of the processing material data.

The two laser heads are used to cut the same pattern simultaneously, doubling the efficiency without taking up extra space or labor. If you always need to cut a lot of repeating patterns, this will be a good choice for your production.

If you want to cut a lot of different designs in a roll and save material to the greatest extent, nesting software is a good choice. Select all the patterns you want to cut in one roll, set the numbers of each piece you want to cut, and then the software will nest these pieces with the most usage rate to save your cutting time and materials. You can send the whole nesting marker to the laser cutter and the machine will cut it without any human intervention.

The Fifth Generation Software

Goldenlaser patented software has more powerful functions, stronger applicability and higher reliability, bringing users a full range of super experience.

Intelligent interface, 4.3-inch color touch screen

The storage capacity is 128M and can store up to 80 files

The use of net cable or USB communication

Laser Cutting Engraving Samples

AWESOME WORKS THAT THE CO2 LASER CUTTER HAS CONTRIBUTED TO

Process Materials: Fabric, leather, foam, paper, microfiber, PU, film, plastic, etc.

Application: Textile, garment, shoes, fashion, soft toys, applique, automotive interiors, upholstery, advertising, printing and packaging, etc.

Technical Parameters of MARS Series Conveyor Belt Laser Machine

| Laser Type | CO2 DC glass laser tube |

| Laser Power | 80W / 110W / 130W / 150W |

| Working Area | 1600mm×1000mm |

| Working Table | Conveyor working table |

| Motion System | Step motor / Servo motor |

| Positioning Accuracy | ±0.1mm |

| Cooling System | Constant temperature water chiller |

| Exhaust System | 550W / 1.1KW Exhaust fan |

| Air Blowing System | Mini air compressor |

| Power Supply | AC220V ± 5% 50/60Hz |

| Graphic Format Supported | AI, BMP, PLT, DXF, DST |

| External Dimensions | 2480mm (L)×2080mm (W)×1200mm (H) |

| Net Weight | 730KG |

※ Note: As products are constantly updated, please contact us for the latest specifications.

MARS Series Laser Systems Summary

1. Laser Cutting Machine with Conveyor Belt

| Model No. |

Laser head |

Working area |

| MJG-160100LD |

One head |

1600mm×1000mm |

| MJGHY-160100LD II |

Dual head |

|

| MJG-14090LD |

One head |

1400mm×900mm |

| MJGHY-14090D II |

Dual head |

|

| MJG-180100LD |

One head |

1800mm×1000mm |

| MJGHY-180100 II |

Dual head |

|

| JGHY-16580 IV |

Four head |

1650mm×800mm |

2. Laser Cutting Engraving Machine with Honeycomb Working Table

| Model No. |

Laser head |

Working area |

| JG-10060 |

One head |

1000mm×600mm |

| JG-13070 |

One head |

1300mm×700mm |

| JGHY-12570 II |

Dual head |

1250mm×700mm |

| JG-13090 |

One head |

1300mm×900mm |

| MJG-14090 |

One head |

1400mm×900mm |

| MJGHY-14090 II |

Dual head |

|

| MJG-160100 |

One head |

1600mm×1000mm |

| MJGHY-160100 II |

Dual head |

|

| MJG-180100 |

One head |

1800mm×1000mm |

| MJGHY-180100 II |

Dual head |

3. Laser Cutting Engraving Machine with Table Lifting System

| Model No. |

Laser head |

Working area |

| JG-10060SG |

One head |

1000mm×600mm |

| JG-13090SG |

1300mm×900mm |

MARS Series Conveyor Worktable Laser Cutting Systems

Applicable Materials and Industries

Apparel industry: garment accessories cutting (label, applique), collar and sleeve cutting, garnent decorative accessories cutting, apparel samples making, pattern making, etc.

Shoe industry: 2D/3D shoe upper, warp knitting shoe upper, 4D printing shoe upper. Material: Leather, synthetic leather, PU, composite material, fabric, microfiber, etc.

Bags and suitcases industry: engraving, cutting and perforating leather or textile of complex text and graphics.

Automotive industry: Suitable for cloth cover of car seat, fiber cover, seat cushion, season cushion, light-aviod mat, truck mat, car side-kick mat, large surrounded mat, car carpet, steering wheel cover, explosion-proof membrane. Material: PU, microfiber, air mesh, sponge, sponge+cloth+leather composite, wollens, fabrics, cardboard, kraft paper, etc.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?