Double Head Inkjet Line Drawing Machine for Shoe Upper / Vamp

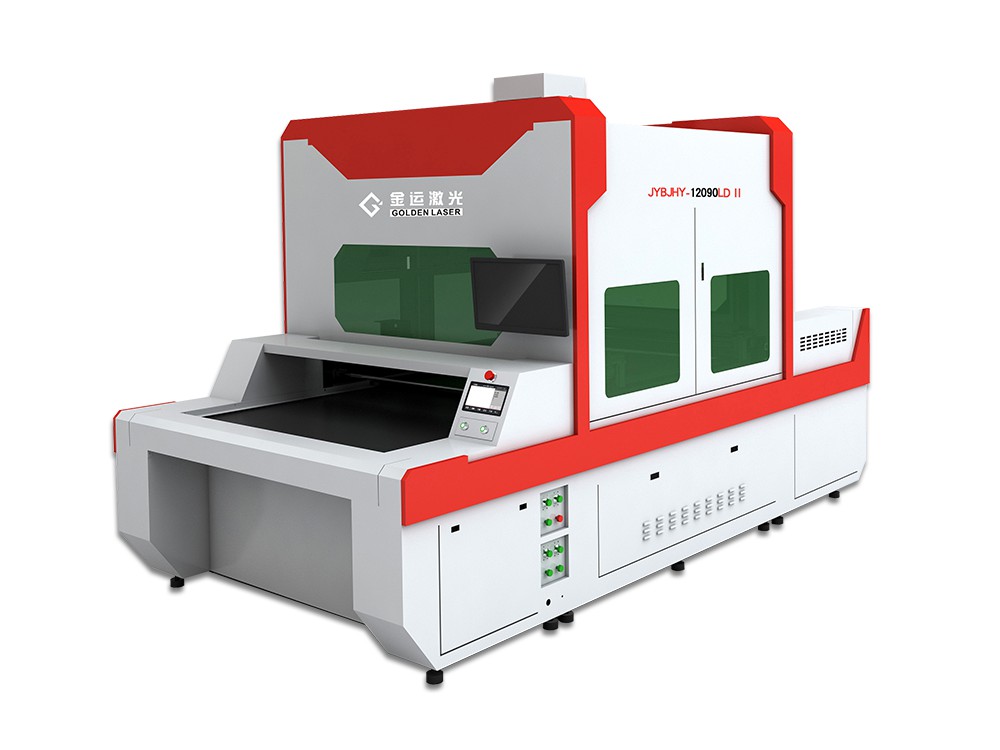

Model No.: JYBJ-12090LD

Introduction:

JYBJ12090LD automatic inkjet machine is specially designed for precise stitching line drawing of shoe materials. The equipment can perform automatic recognition of the type of cut pieces and precise positioning. It is high-speed, high-precision and assembly line processing flow. The whole machine is automatic, intelligent, and easy to learn.

In the shoe industry, precise drawing of the stitching line of the shoe piece is an indispensable process Traditional manual drawing not only requires a lot of labor, its quality also depends entirely on the proficiency of the workers.

Goldenlaser JYBJ12090LD automatic inkjet machine is specially designed for precise stitching line drawing of shoe materials. The equipment can perform automatic recognition of the type of cut pieces and precise positioning. It is high-speed, high-precision and assembly line processing flow. The whole machine is automatic, intelligent, and easy to learn.

The simplification of processes and the replacement of labor by machines are the way out for factories in the future. Therefore, goldenlaser launched a fully automatic inkjet stitching line drawing machine to help shoe factories save labor, improve efficiency, and save costs.

Workflow

Machine Features

Watch Double Head Inkjet Seams Line Drawing for Shoe Vamp in Action!

Technical Parameters

| Model No. | JYBJ-12090LD |

| Maximum working speed | 1,000mm/s |

| Acceleration | 12,000mm/s2 |

| Repeating positioning accuracy | ≤0.05mm |

| Positioning accuracy | ≤0.1mm/m |

| Recognition accuracy | ≤0.2mm |

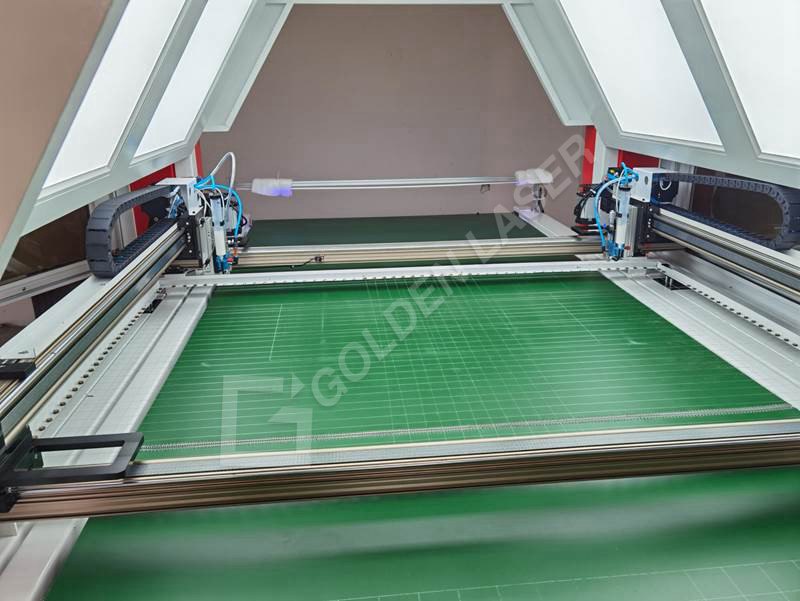

| Working table | Rubber belt driving transmission working table |

| Working table height | 750mm |

| Transmission system | Synchronous belt module transmission |

| Control system | Servo control system |

| Vision positioning | 2.4M pixels industrial camera |

| Noise | ≤65Dd |

| Power supply | AC220V±5% 50Hz |

| Power consumption | 3KW |

| Software | Golden Laser Vision Positioning Software |

| Graphic formats supported | AI, BMP, PLT, DXF, DST |

*** Note: As products are constantly updated, please contact us for the latest specifications. ***

JYBJ-12090LD → Single head

JYBJ-12090LD II → Double head

Suitable for various shoe materials such as leather, PU, microfiber, synthetic leather, natural leather, cloth, knitted fabric, mesh fabric, etc.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?

4. Your company name, website, Email, Tel (WhatsApp / WeChat)?