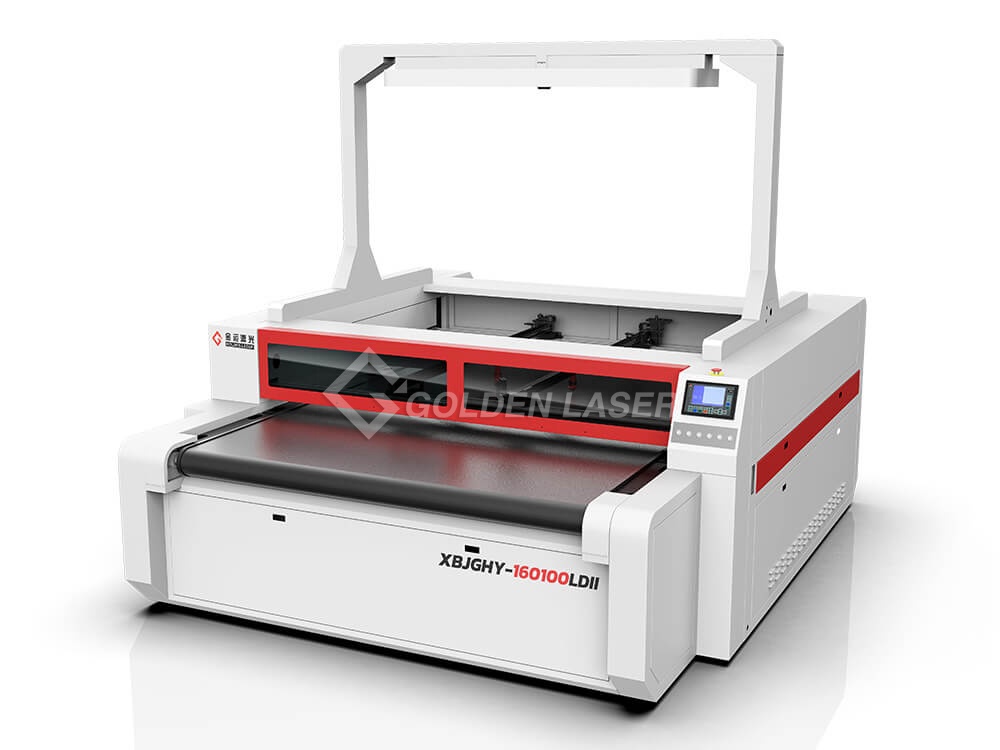

Independent Dual Head Camera Laser Cutting Machine

Model No.: QZDXBJGHY-160100LDII

Introduction:

- Two heads work independently, high processing efficiency.

- Using HD camera, high recognition accuracy.

- Cutting by directly contour capturing.

- Supporting manual adjusting through software to solve the problem of material distortion.

- Automatic feeder option to realize continuous processing.

Independent Dual Head Cutting System:

Double heads cut different patterns independently, and the software can assign the nested jobs to each head to achieve high efficiency.

Smart Vision Camera System:

The laser machine is equipped with powerful Smart Vision Software and SLR Camera System.

HD Camera is mounted on the top of the laser cutter machine. After the material is fed to the laser cutting table, the camera takes a photo of the printed pattern at once in the entire work area at one time. The software automatically creates a file according to the shape and size of the pattern, and then the laser heads cut precisely along the outline of the pattern. It only takes 10 seconds to take pictures and create files.

Besides for the outline contour detection, you can also use templates for high precision cutting. And the camera has the function as “photo digitize”.

Specifications

Main Technical Specifications of the QZDXBJGHY160100LDII Smart Vision Laser Cutter

| Working area (W×L) | 1600mm×1000mm (63”×39.3”) |

| Laser power | 80W / 130W / 150W |

| Laser source | CO2 glass laser |

| Working table | Conveyor working table |

| Mechanical control system | Belt transmission & Servo motor drive |

| Cutting speed | 1~400mm/s |

| Acceleration speed | 1000~4000mm/s2 |

Availability

Highlights of the Smart Vision Dual Head Laser Cutting System

Independent Dual Heads

For the basic two laser heads cutting machine, the two laser heads are mounted in the same gantry, so they can only be used for the same patterns cutting. While for dye sublimation products, there are always many different types of print pieces, big pieces, or small pieces, all the pieces are different such as jerseys front, back, sleeves. The independent dual heads can cut different designs at the same time; so, it increases the cutting efficiency and production flexibility at the largest degree. Output increase ranges from 30% to 50% depends on what you cut.

Outline Contour Detection

The software detects the contour according to the big color difference between the printing outline and materials background. You do not have to use the original patterns or files; it is a fully automatic process without manual intervention. Detection of printed fabrics directly from rolls, without any preparation; and because the camera takes photos after the fabric is feeding to the cutting area, the precision will be very high.

Templates

When you cut very high distortion materials or need super high precision for patches, logos, you can use the templates instead of contour cut; the process is the software load your original design templates, and then camera take a photo and compare with your templates, then cut exactly the same size you want to cut; and you can set offset distance according to your production requirements.

Photo Digitize

If you do not always design by yourself or do not have the designers in your workshop, you can also use this machine as a “photo digitize” system. For example, you can put a garment piece underneath the camera, you can use the camera to take a photo of the garment piece and save it as a pattern files in your PC; next time you can use this pattern as a design pattern.

Application

Application Industries of the Smart Vision Dual Head Laser Cutter Maachine

Active wear, leggings, sportswear (cycling wear, hockey jerseys, baseball jerseys, basketball jerseys, soccer jerseys, volleyball jerseys, lacrosse jerseys, ringette jerseys), uniforms, swimwear, arm sleeves, leg sleeves, bandanna, headband, dye sublimation pillows, rally pennants, face cover, masks, Sublimation printed apparel, dye-sublimation products, digital printed graphics, flags, knitting vamp, mesh fabric sports shoe upper, toys, patches, etc.

Demo Video

Smart Vision Dual Heads Laser Cutting Machine for Sublimation Masks

Technical Parameters

| Laser Type | CO2 glass laser tube |

| Laser Power | 80W / 130W / 150W |

| Working Area (W×L) | 1600mm×1000mm (63”×39.3”) |

| Maximum material width | 1600mm (63”) |

| Working table | Conveyor working table |

| Mechanical control system | Belt transmission & Servo motor drive |

| Cutting Speed | 1-400mm/s |

| Acceleration | 1000-4000mm/s2 |

| Cooling System | Constant temperature water chiller |

| Software | Goldenlaser Smart Vision Cutting System |

| Power Supply | AC220V ± 5% 50/60Hz |

| Format Supported | AI, BMP, PLT, DXF, DST |

Goldenlaser’s Full Range of Vision Laser Cutting Systems

Ⅰ Smart Vision (Dual Head) Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDMJG-180100LD | 1800mm×1000mm (70.8”×39.3”) |

| QZDXBJGHY-160100LDII | 1600mm×1000mm (63”×39.3”) |

Ⅱ High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1300mm (63”×51”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

Ⅲ High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ⅳ Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Ⅴ CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

Smart vision laser cutting system can be applied to the following industries:

- Digitally printed or dye-sublimated textile graphics

- Sportswear, Swimwear, cycling apparel, T Shirt, Polo shirt

- Warp fly knitting vamp, sport shoe upper

- Flags, toys

- Printed label, printed letter, number, logo

- Clothing embroidery patches, woven label, applique

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?