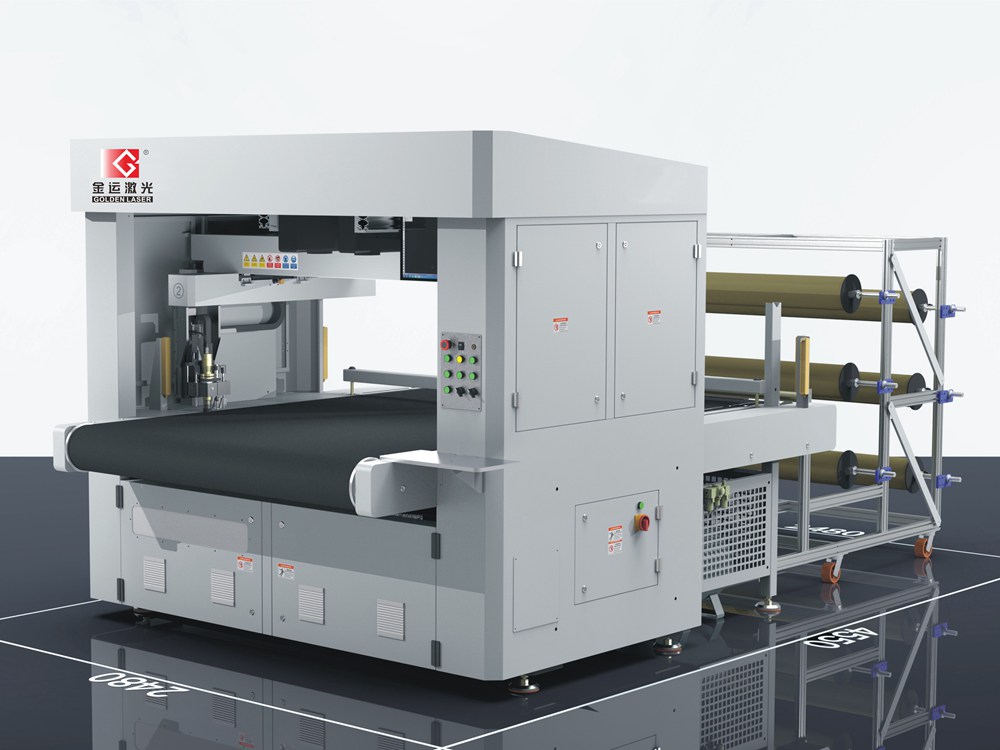

Dual Head Oscillating Knife Cutting Machine for Shoe Components

Model No.: VKP16060 LD II

Introduction:

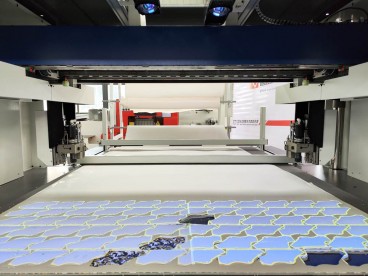

- 2 projectors, real-time preview of nesting layout.

- Independent dual head, cutting and punching multi-layer materials.

- Smart nesting system, easy to operate and saving material.

- Multi-layer spreading, automatic synchronous feeding.

- Automatic material pulling, continuous cutting.

Oscillating Knife Cutting Machine

Watch Oscillating Knife Cutting for Shoe in Action!

Features

Smart Nesting

Graphics can be graded, modified and intelligently nested by special software. The software can lay out materials according to the nesting, minimizing material waste.

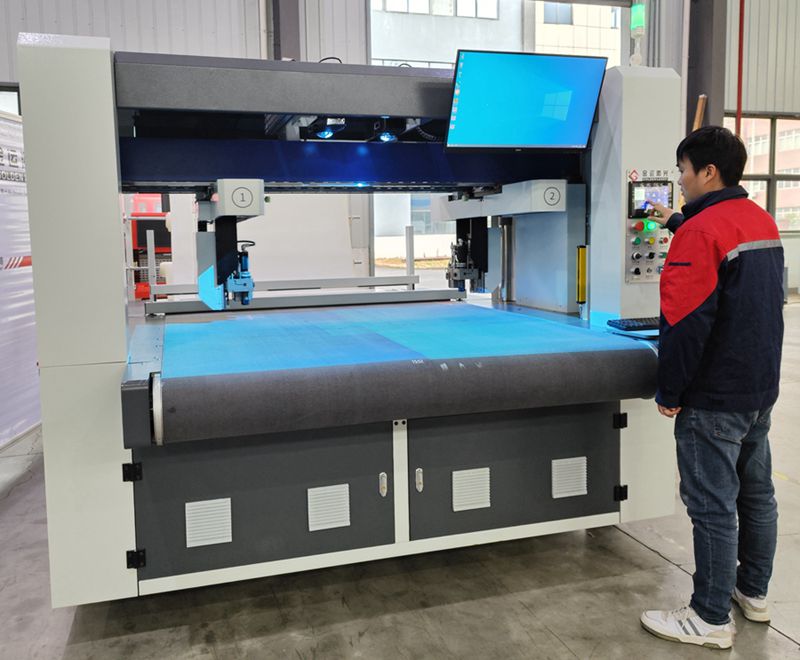

Automatic spreading

Automatic multi-layer spreading and loading according to nesting requirements, up to 10 layers at a time, effectively saving manual spreading time and increasing production efficiency.

Automatic cutting

Fast and precise cutting, smooth edges without jaggedness, no yellowing or scorching. Multi-layer cutting is possible.

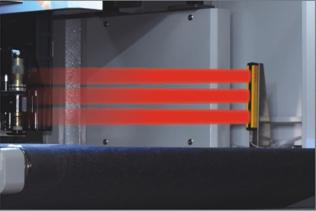

Automatic punching

Servo control, die punching technology, precise positioning and punching. Different shapes and sizes of patterns can be punched by changing the punch.

Configurations

Technical Parameters

|

Working area |

1600mmx700mm |

|

Working table |

Aluminum alloy honeycomb platform + conveying carpet |

|

Material fixation method |

Vacuum absorption |

|

Max material processing weight |

≤10mm (Depending on different material) |

|

Max processing speed |

72m/min |

|

Positioning method |

Projection positioning |

|

Repeatable cutting accuracy |

±0.2mm |

|

Drive system |

Servo motor, linear guide and lead screw drive |

|

Number of motor |

9 Axis |

|

Graphics formats supported |

AI, EPS, DXF, PLT, PDF, JPG, TIF, TPS |

|

Equipment power |

4.5KW |

|

Vacuum pump power |

11KW |

|

Power supply |

380V / 50Hz (3 phases) |

|

Overall diameter |

4500mmx2415mmx2020mm |

|

Net weight |

2200kg |

Application

Suitable for cutting and punching in the shoe, luggage, glove and hat industries.

Cutting Samples

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What material do you need to cut?

2. What is the size and thickness of the material?

3. What is your final product? (application industry)

4. Your company name, website, Email, Tel (WhatsApp / WeChat)?