Laser Cutting Machine for Textile Duct

Model No.: JMCZJJG(3D)-250300LD

Introduction:

- Combination of large format X,Y axis laser cutting (trimming) and high speed Galvo laser perforating (laser cut holes).

- Laser perforating uniform small holes with minimum size of 0.3mm.

- Automated production process with feeding, conveyor and winding systems.

- Ultra-long format processing by continuation of cuts possible.

Watch Laser Cutting Machine for Textile Duct in Action!

Benefits of Laser Cutting Fabric Duct

Laser Cutting Air Duct

Machine Features

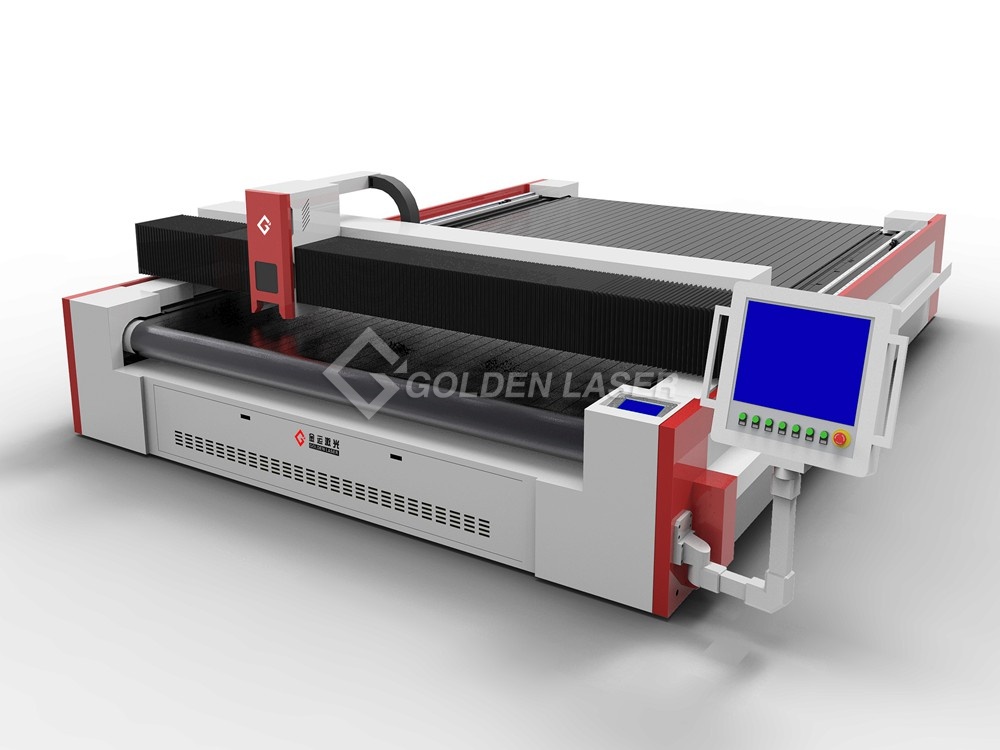

Goldenlaser specially developed CO2 laser cutting machine for textile ducts

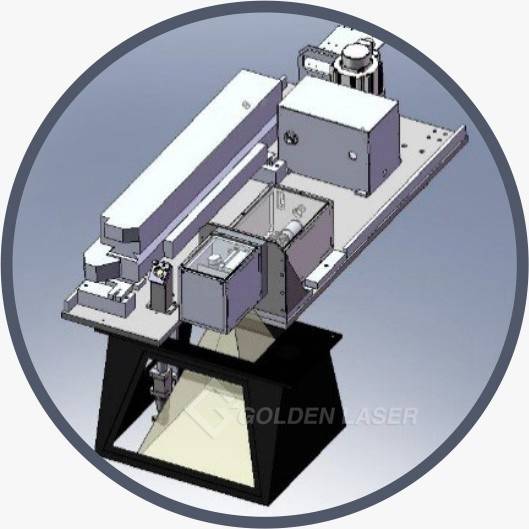

| Galvo System - Dynamic Focus | |

| Galvanometer Scanner | SCANLAB (Germany) |

| Scan Area | 450mm×450mm |

| Laser Spot Size | 0.12mm~0.4mm |

| Processing Speed | 0~10,000mm/s |

One of our Textile Ventilation Ducting Customers' Processing Workshop

- Goldenlaser’s Laser Cutting Machine in Operation

Technical Parameter

| Laser type | CO2 RF metal laser |

| Laser power | 150 watt, 300 watt |

| Working area (W×L) | 2500mm×3000mm (98.4” ×118”) |

| Working table | Vacuum conveyor working table |

| Mechanical system | Servo motor, Gear & Rack driven |

| Power supply | AC220V±5% 50/60Hz |

| Graphic format supported | PLT, DXF, AI, BMP, DST |

| Options | Auto feeder, Red dot positioning system, Marking systems |

※ Working areas can be customized on request.

Various table sizes are available: 1600mm×1000mm (63”×39.3”), 1700mm×2000mm (67”×78.7”), 1600mm×3000mm (63”×118”), 2100mm×2000mm (82.6” ×78.7”) ... Or other options.

| Specifications of the Laser Cutting Machine for Fabric Duct | |

| Model No. | JMCZJJG(3D)-250300LD |

| Laser type | CO2 RF metal laser |

| Laser power | 150 watt, 300 watt |

| Working area (W×L) | 2500mm×3000mm (98.4” ×118”) |

| Working table | Vacuum conveyor working table |

| Perforation system | Galvo system |

| Cutting system | X-Y Gantry cutting |

| Cutting speed | 0~1200mm/s |

| Acceleration | 8000mm/s2 |

| Mechanical system | Servo motor, Gear & Rack driven |

| Power supply | AC220V±5% 50/60Hz |

| Graphic format supported | PLT, DXF, AI, BMP, DST |

| Options | Auto feeder, Red dot positioning system, Marking systems |

※ Working areas can be customized on request.

Various table sizes are available: 1600mm×1000mm (63”×39.3”), 1700mm×2000mm(67”×78.7”), 1600mm×3000mm (63”×118”), 2100mm×2000mm (82.6” ×78.7”) Or other options.

|

Goldenlaser’s Typical Models of Laser Cutting Machine for Industrial Fabrics |

|

|

JMCZJJG Series |

JMCCJG Series |

|

Gantry & Galvo Laser |

Flat Bed Laser Cutter |

|

|

| Application Industry and Materials |

| Applicable Industry |

| Fabric Ducting (Textile Ventilation Duct, Air Sock, Air Sox, Sock Duct, Sox Duct, Duct Sox, Duct Sock, Textile Air Duct, Air Distribution) |

| Applicable Materials |

|

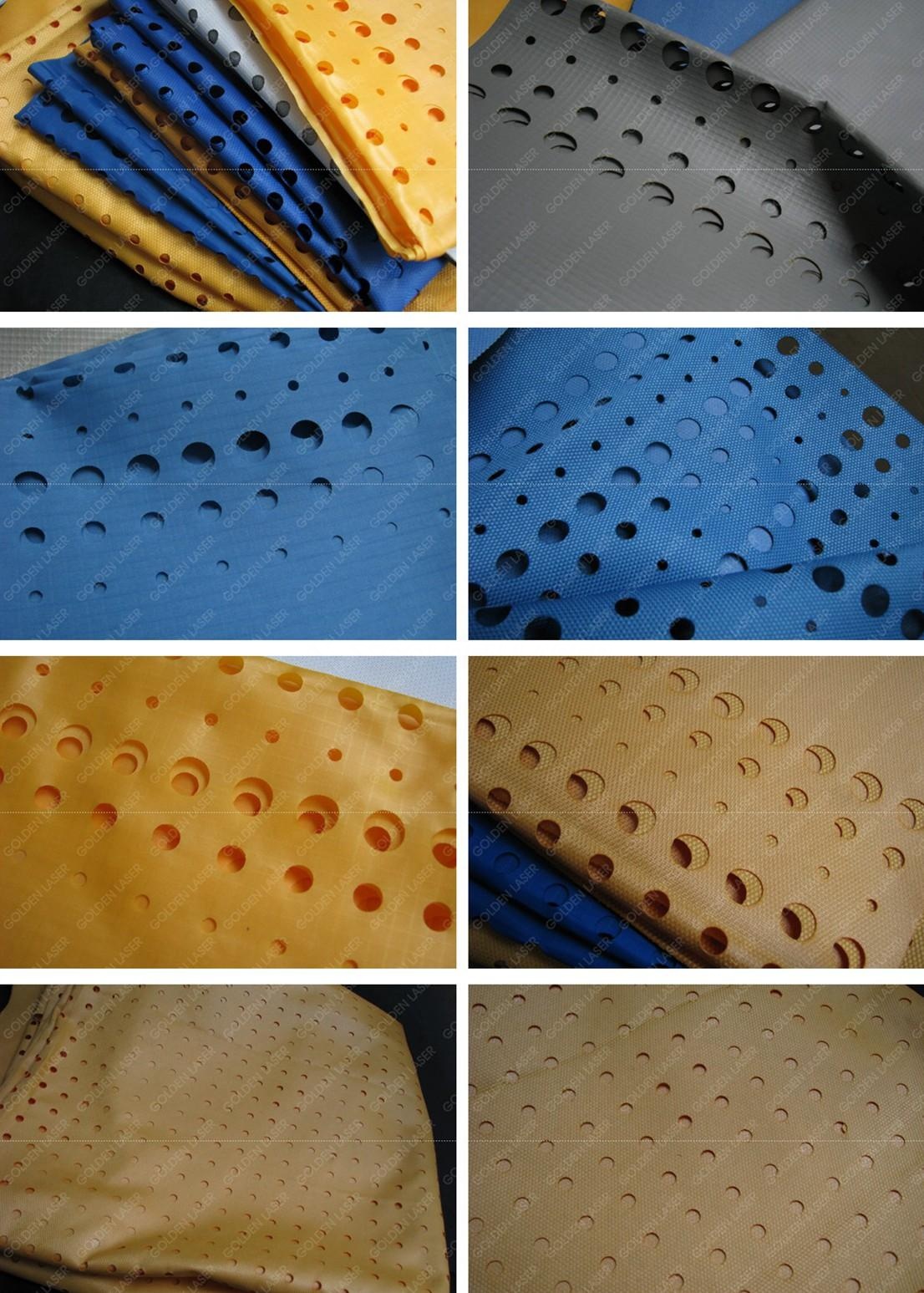

Laser Cutting Fabric Duct Samples

Please contact GOLDEN LASER for more infomation. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?