- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

Fast delivery for Automatic Bundle Loader Fiber Laser Pipe Cutting Machine for London Factories

Fast delivery for Automatic Bundle Loader Fiber Laser Pipe Cutting Machine for London Factories Detail:

Automatic Bundle Loader Fiber Laser Pipe Cutting Machine

Advanced chuck clamping system

◇ Chuck center self-adjustment, automatically adjust the size of the clamping force according to the profile specifications, to ensure non-destructive thin tube clamping.

◇ Two linked right move claws, compatible with a variety of pipe without adjusting jaws.

Corner fast cutting system

◇ Corner fast response, greatly improving cutting efficiency.

Lift adjustable support system

◇ Simple change pipe type, installed to save time, reduce pipe swing.

◇ Auxiliary loading and unloading system perfect switch.

Automatic collecting

◇ Automatic elevating support, receive tube and scrap into the basket.

◇ Visual scale support can adjust support diameter quickly according to pipe diameter.

◇ Visual scale adjustable support lifting device saves feeding time, ensures concentricity, prevents pipe swing.

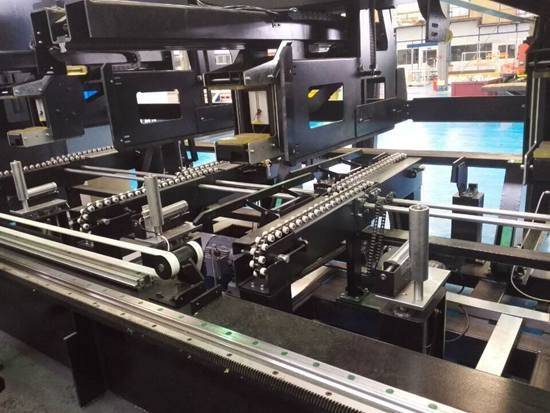

Automatic Bundle Loader

◆ Round pipe, rectangular pipe and other pipes can be fully automated loading. Other shapes pipe can be semi-automatic feeding manually.

General Details

General Details

◆ Maximum loading bundle 800mm×800mm

◆ Maximum loading bundle weight 2500Kg

◆ The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers.

◆ The tape support frame for easy disassembly.

◆ Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport.

◆ The pneumatic system components used AirTAC or other more high-end brand. PLC control, sensors selected Omron, Schneider and other well-known brand. Ensure the stability of the system and export standard.

Golden Laser - Fiber Laser Tube Cutting Machine

Laser Cutting Tube in Batch Production