Would you like to get more options and availability of goldenlaser machines and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

Full Flying Galvo Laser Cutting and Marking Machine with Camera

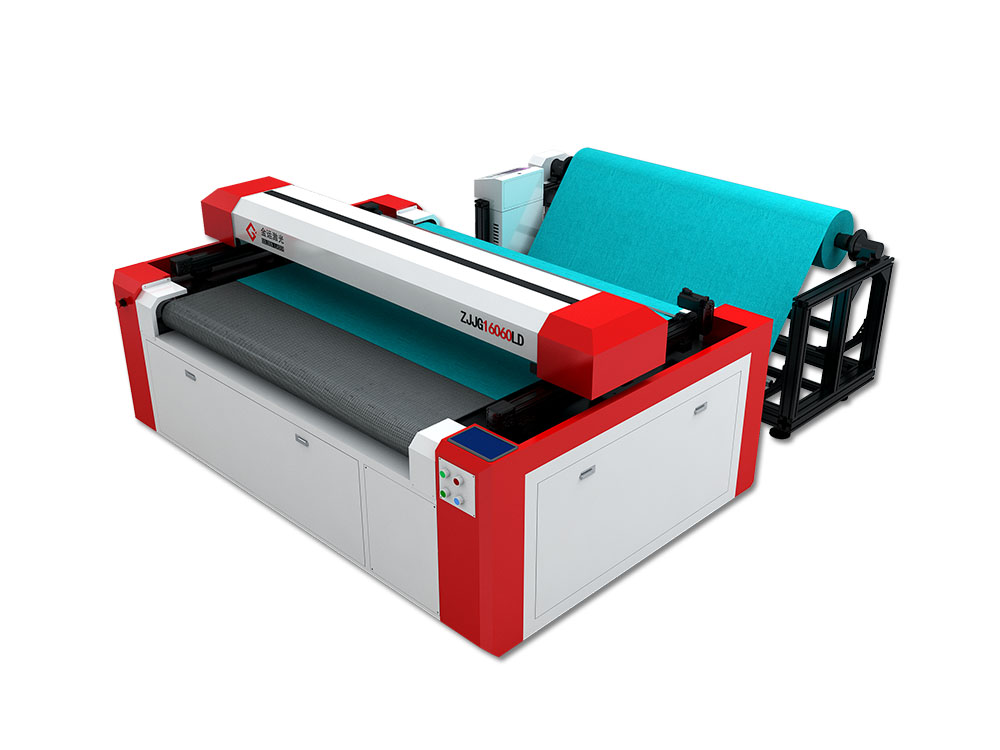

Model No.: ZJJG-16080LD

Introduction:

- The combo laser system combines Glavo and X-Y gantry laser heads, sharing one laser tube.

- Equipped with a CCD camera for Galvo head calibration and registration marks recognition.

- 80 Watts CO2 glass laser tube

- Working area 1600mmx800mm (1600mmx600mm, 1600mmx1000mm optional)

- Conveyor table (Or honeycomb table)

- Can be configured as a “Smart Vision” upgrade version, with a big camera (overhead)

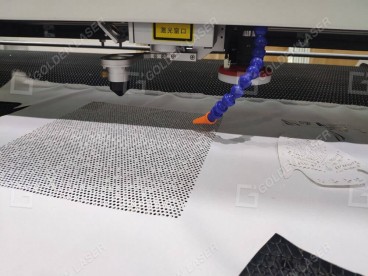

This CO2 laser machine combines galvanometer and X-Y gantry, sharing one laser tube. The galvanometer offers high speed marking, scoring, perforating and cutting of thin materials, while X-Y Gantry allows processing of thicker stock.

With 1600mm×600mm working area, it gives you enough space to process the majority of cutting and marking application, such as cutting large format heat transfer vinyl for apparel application. When you start new project and want to take a test drive on Galvo laser marking machine, ZJJG-16060LD is the way to go. Small investment with high ROI can generate considerable profit and increase production efficiency.

FEATURES

Watch ZJJG-16080LD CO2 Laser Machine Working in Action

SPECIFICATIONS

| Working Area (W×L) | 1600mm×800mm (63”×31.5”) |

| Beam Delivery | Galvanometer & Normal Laser Head |

| Laser Source | CO2 Glass Laser Tube |

| Laser Power | 80W |

| Mechanical System | Servo Motor, Belt Driven |

| Working Table | Conveyor Working Table |

| Max. Cutting Speed | 1~1,000mm/s |

| Max. Marking Speed | 1~2,000mm/s |

| Options | CO2 RF metal laser tube, Auto-feeder |

AVAILABILITY

Processing Available:

Process Materials:

Textiles (natural and technical fabrics), denim, leather, PU leather, wood, acrylic, PMMA, paper, vinyl, EVA, rubber, plastic and other non-metal materials, etc.

Application:

Garments accessories, shoes, scarfs, gift cards, labels, packing, puzzles, heat-transfer vinyl, fashion (sportswear, denim, footwear, bags), interior (carpets, curtains, sofas, armchairs, textile wallpaper), technical textiles (automotive, airbags, filters, air dispersion ducts), etc.

SAMPLES

"Smart Vision" upgrade version

The Galvo & Gantry Laser Machine can be configured as a "Smart Vision" upgrade version, with a big camera (overhead) and a CCD camera, specially for cutting and perforating of dye sublimated sportswear, fabrics, tackle twill letters, numbers, logos.

Equipped with a 20-megapixel HD camera, it provides accurate positioning for laser perforation and cutting through real-time scanning and calculation by software and automatic recognition and calibration by intelligent system.

This is a highly efficient and versatile laser machine that integrates high-definition camera precise positioning and high-speed dual-flying laser perforation and cutting.

Watch Smart Vision Galvo & Gantry Laser Working in Action

Looking for further information?

Technical Parameters of ZJJG-16080LD

| Working Area (W×L) | 1600mm×800mm (63” × 31.5”) |

| Beam Delivery | Galvanometer & Gantry |

| Laser Source | CO2 Glass Laser Tube |

| Laser Power | 80W |

| Mechanical System | Servo Motor, Belt Driven |

| Working Table | Conveyor Working Table |

| Max. Cutting Speed | 1~1,000mm/s |

| Max. Marking Speed | 1~2,000mm/s |

| Options | CO2 RF metal laser tube, Auto-feeder |

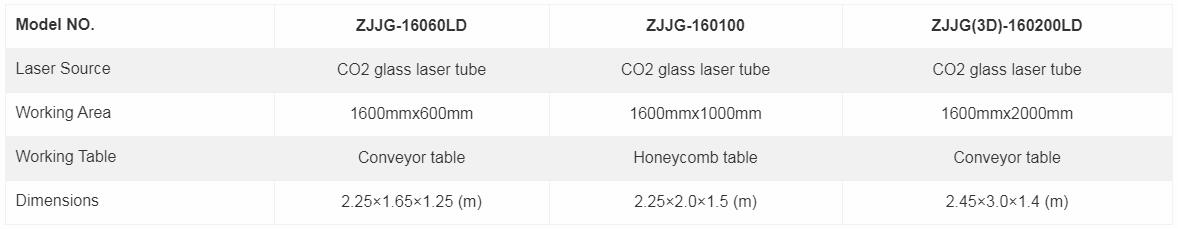

Full Flying CO2 Galvo Laser Cutting and Marking Machines with Camera

Note: Laser source, laser power and processing format can be customized on request.

Process Materials:

Textiles (natural and technical fabrics), denim, leather, PU leather, wood, acrylic, PMMA, paper, vinyl, EVA, rubber, plastic and other non-metal materials

Application:

Garments accessories, shoes, gift cards, labels, packing, puzzles, heat-transfer vinyl, fashion (sportswear, denim, footwear, bags), interior (carpets, curtains, sofas, armchairs, textile wallpaper), technical textiles (automotive, airbags, filters, air dispersion ducts)

Please contact goldenlaser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?