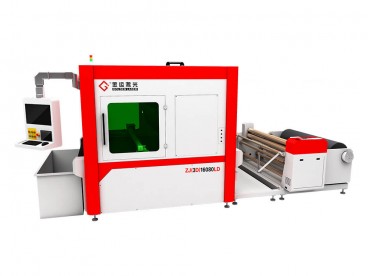

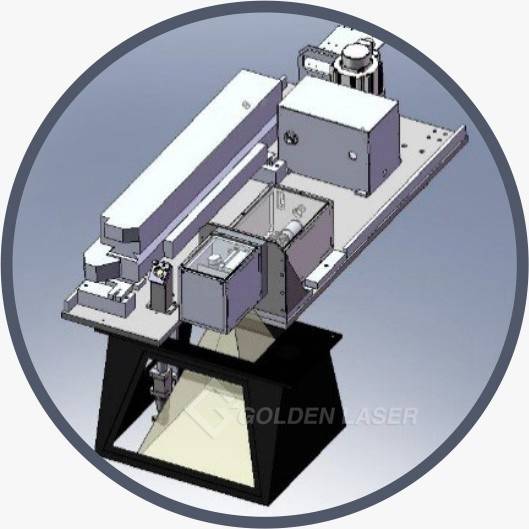

Galvo Laser Cutting and Perforating Machine for Jersey Fabric

Model No.: ZJJG(3D)170200LD

Introduction:

- A versatile laser machine integrated Gantry & Galvo that can do cutting, perforating and engraving for jerseys, polyester, microfiber, even stretch fabric.

- 150W or 300W RF metal CO2 lasers.

- Working area: 1700mm×2000mm (66.9” * 78.7”)

- Conveyor working table with auto feeder.

High Speed Galvo & Gantry Combination Laser Machine

MODEL: ZJJG(3D)170200LD

√ Cutting √ Engraving √ Perforating √ Kiss Cutting

ZJJG(3D)170200LD is an excellent choice for sports jersey cutting and perforating.

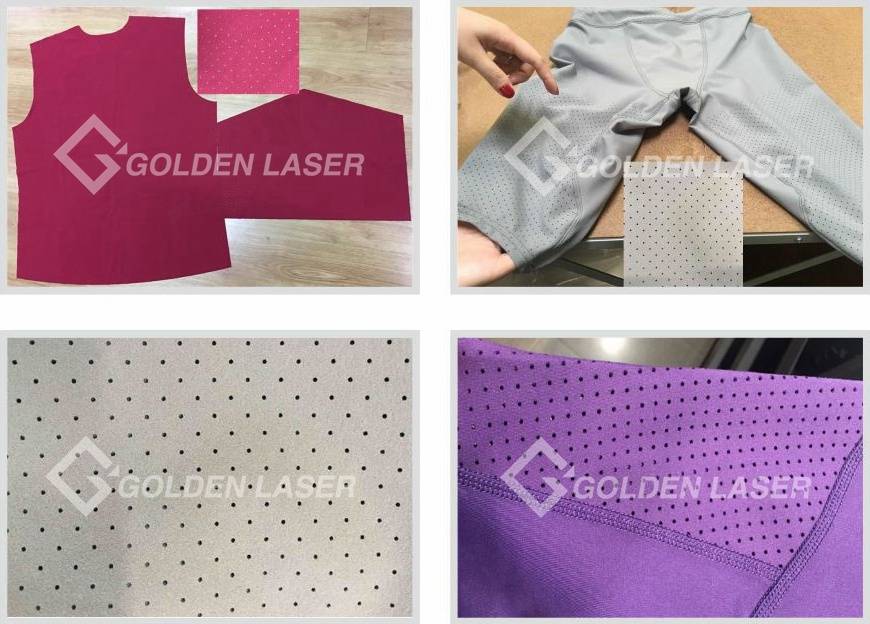

There are two different processes to make sportswear with breathability. One typical method is to use sportswear fabrics that already have the breathing holes. These holes are made when knitting, and we call it “pique mesh fabrics”. The main fabrics composition is cotton, with small polyester. The breathability and moisture wicking function is not so good.

Another typical fabric that widely used is dry fit mesh fabrics. This is normally for standard level sportswear application.

However, for the high-end sportswear, the materials are usually high polyester, spandex, with high tension, high elasticity. These functional fabrics are very expensive and are widely used in athletes' jerseys, fashion designs, and high value-added clothing. Breathing holes are generally designed in some special parts of the jerseys such as underarm, back, short legging. Special fashion designs of breathing holes are also widely used for active wear.

Main Features

This laser machine combines galvanometer and X-Y gantry, sharing one laser tube. The galvanometer offers high speed engraving, perforating and marking, while X-Y Gantry allows laser cutting patterns after Galvo laser processing.

Conveyor vacuum working table is suitable for the materials both in roll and in sheet. For roll materials, an automatic feeder can be equipped for automatic continuous machining.

Comparison of Galvo Laser, X-Y Gantry Laser & Mechanical Cutting

| Cutting methods | Galvo laser | X-Y Gantry laser | Mechanical cutting |

| Cutting edge | Smooth, sealed edge | Smooth, sealed edge | Fraying edge |

| Drag on material? | No | No | Yes |

| Speed | High | Slow | Normal |

| Design limitation | No Limitation | High | High |

| Kiss cutting / marking | Yes | No | No |

More Application Industries

- Fashion (sportswear, denim, footwear, bags);

- Interior (carpets, mats, curtains, sofas, textile wallpaper);

- Technical textiles (automotive, airbags, filters, air dispersion ducts)

Watch Galvo Laser Cutting and Perforating Machine for Jersey Fabric in Action!

Technical Parameter

| Working Area | 1700mm × 2000mm / 66.9″ × 78.7″ |

| Working Table | Conveyor working table |

| Laser Power | 150W / 300W |

| Laser Tube | CO2 RF metal laser tube |

| Cutting System | X-Y Gantry cutting |

| Perforation / Marking System | Galvo system |

| X-Axis Drive System | Gear and rack drive system |

| Y-Axis Drive System | Gear and rack drive system |

| Cooling System | Constant temperature water chiller |

| Exhaust System | 3KW exhaust fan × 2, 550W exhaust fan × 1 |

| Power Supply | Depends on laser power |

| Power Consumption | Depends on laser power |

| Electrical Standard | CE / FDA / CSA |

| Software | GOLDEN LASER Galvo software |

| Space Occupation | 3993mm(L) × 3550mm(W) × 1600mm(H) / 13.1’ × 11.6’ × 5.2’ |

| Other Options | Auto feeder, red dot positioning |

| *** Note: As products are constantly updated, please contact us for latest specifications. *** | |

→ High Speed Galvo Laser Cutting and Perforating Machine for Jersey ZJ(3D)-170200LD

→ Multifunction Galvo Laser Machine with Conveyor Belt and Auto Feeder ZJ(3D)-160100LD

→ High Speed Galvo Laser Engraving Machine with Shuttle Working Table ZJ(3D)-9045TB

Applicable materials and industry

Suitable for polyester, microfibre fabric (textile), cellucotton, polyester fibre, etc.

Suitable for jerseys, sportswear, sports shoes, wiping cloth, non-dust cloth, paper diapers, etc.

<< Read More about Galvo laser perforating and cutting of fabrics

People are increasing emphasis on sports and health, while have increasingly high requirements for the sports jersey and shoes.

The comfort and breathability of jersey is very concerned by sportswear manufacturer. Most manufacturers are seeking to change the fabric from the fabric material and structure, and spend a lot of time and effort to promote innovation of fabrics. However, there are many warm and comfortable fabrics with poor ventilation or wicking capabilities. Therefore, the brand manufacturers shift attention to the laser technology.

Combining technical fabrics and laser technology to deep processing of fabrics, is another innovation of sportswear. Its comfort and permeability is also favored by sports stars.

Please fill out the form below to get more information about this laser machine.

We will gladly advise you about cutting and perforating of jerseys fabric to our laser systems and special options for the processing of textile.