Galvo Laser Leather Engraving Cutting Machine for Shoe Industry

Model No.: ZJ(3D)-160100LD

Introduction:

- Laser engraving, perforating and cutting can be done in one step.

- Dual driving system with gear rack structure.

- Optimized galvanometer system.

- Top speed and Large format processing.

BENEFIT

High Speed

High speed double gear rack driving system

Galvo & Gantry Integration

Fast Galvo engraving and large format X-Y axis cutting

High Precision

Precise laser beam size up to 0.2mm

Multi-function

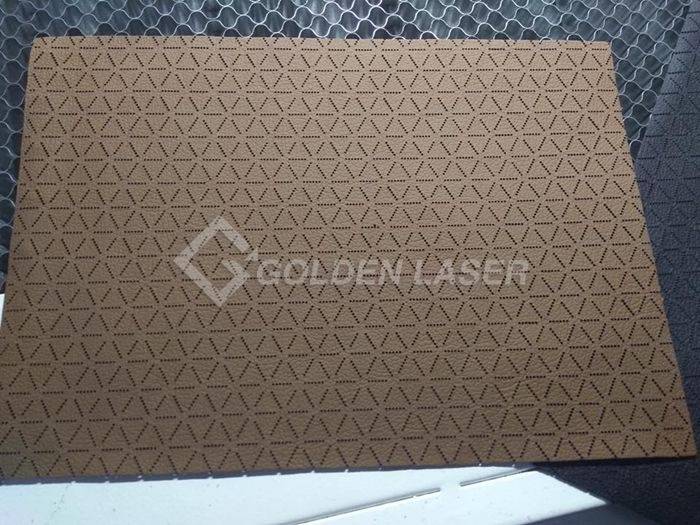

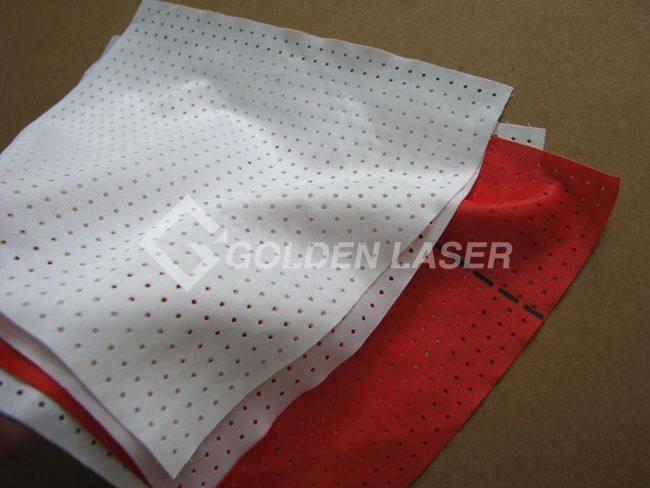

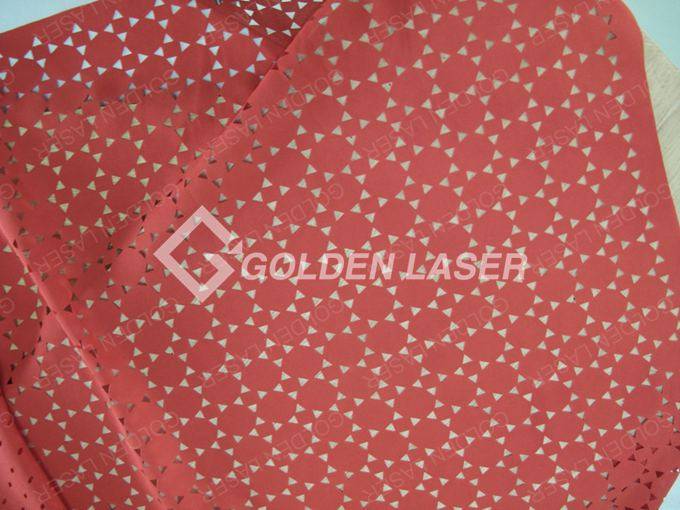

Engraving, perforating, hollowing, cutting of various leather and textile

Flexible

Processing any design. Save tool cost, save labor cost and save materials

Automated

Automatic laser processing roll to roll thanks to conveyor system and auto feeder

Demo Video - How Galvo Laser Machine Works?

LASER ENGRAVING, CUTTING AND PERFORATING OF LEATHER DIRECTLY FROM ROLL AT HIGH SPEED

Technical Parameters

| Model NO. | ZJ(3D)160100LD |

| Laser type | CO2 RF metal laser tube |

| Laser Power | 150W / 300W / 600W |

| Galvo system | 3D dynamic system, galvanometer laser head, scanning area 450×450mm |

| Working area | 1600mm×1000mm (62.9in×39.3in) |

| Working table | Zn-Fe honeycomb vacuum conveyor working table design |

| Motion system | Servo motor |

| Power supply | AC220V±5% 50/60Hz |

| Standard configuration | Constant temperature water chiller, Exhaust fans, Air compressor |

| Optional configuration | Auto feeder, Filtration device, Exhaust system building |

※ Appearance and specifications are subject to change due to updating.

GOLDENLASER – Laser Machines for Shoe Industry Overview

| Products | Laser type & power | Working area |

| XBJGHY160100LD Independent Dual Head Laser Cutting Machine | CO2 glass laser 150W×2 | 1600mm×1000mm (62.9in×39.3in) |

| ZJ(3D)-9045TB Galvo Laser Engraving Machine | CO2 RF metal laser 150W / 300W / 600W | 900mm×450mm (35.4in×17.7in) |

| ZJ(3D)-160100LD Galvo Laser Engraving Cutting Machine | CO2 RF metal laser 150W / 300W / 600W | 1600mm×1000mm (62.9in×39.3in) |

| ZJ(3D)-170200LD Galvo Laser Engraving Cutting Machine | CO2 RF metal laser 150W / 300W / 600W | 1700mm×2000mm (66.9in × 78.7in) |

| CJG-160300LD / CJG-250300LD Genuine Leather Intelligent Nesting and Laser Cutting System | CO2 glass laser 150W ~ 300W | 1600mm×3000mm (62.9in×118.1in) / 2500mm×3000mm (62.9in×98.4in) |

Multi-function integration of laser engraving, hollowing and cutting leather and fabric from roll.

Please contact GOLDENLASER for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

Or are you a dealer or distributor for the machine?