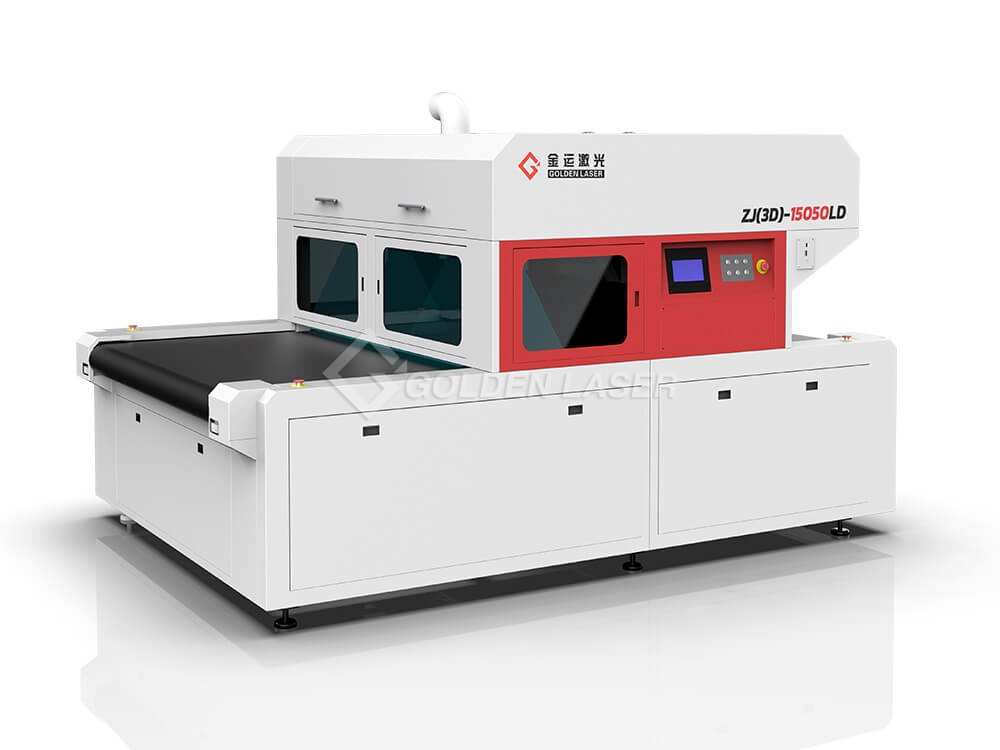

Galvo Laser Perforating Cutting Machine for Sandpaper Abrasive Discs

Model No.: ZJ(3D)-15050LD

Introduction:

- Large-area galvanometer scanning systems.

- Multiple laser sources to increase productivity.

- Automatic feeding and rewinding – conveyor working platform.

- Automated roll to roll processing for abrasive paper.

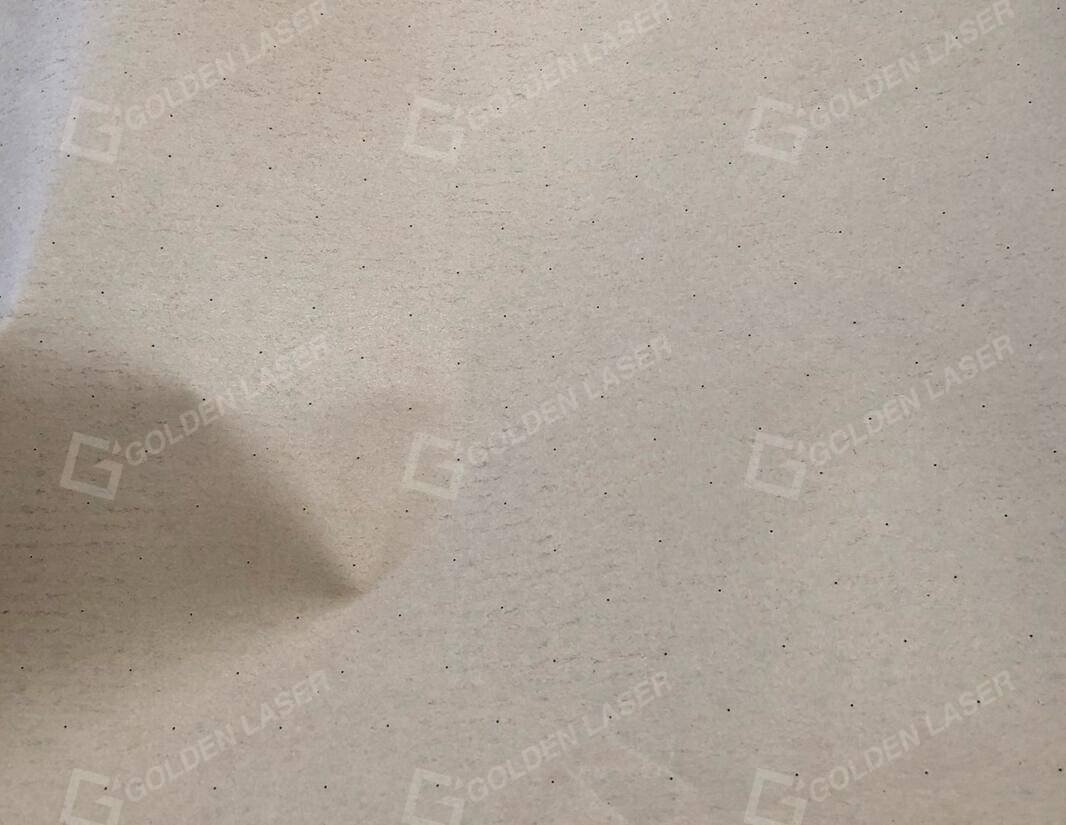

- Fast and efficient. Ultra-fine laser spot. Minimum diameter up to 0.15mm.

Laser Cutting Perforating Machine for Sandpaper

In order to meet the new requirements of abrasive materials manufacturers, GOLDEN LASER developed laser cutting and perforation systems to produce various sizes and shapes, as well as small holes in sandpaper.

Laser offers advantages that outshines traditional method

Clean and perfect laser processing

No burr of cutting edges, no rework necessary

Non-contact laser processing

No tool wear, no deformation of material

Laser beam is always sharp

High repetition accuracy. Consistent superior quality.

Using lasers to produce high quality sandpaper

Laser perforating offers outstanding flexibility and automation capabilities, as well as phenomenal miniaturization potential via spot sizes adjustable down to mere micrometers. Ultra-fine holes are achievable in the sub-millimeter range with very sharp edges and short process times.

Customized Laser Machine Model ZJ(3D)-15050LD

Two Galvo Heads

3D Galvo engraving system (from Germany ScanLab). One time processing area 900×900mm / each head.

Conveyor working table

Conveyor working table 1500×500mm area; Front extended table 1200mm and back extended table 600mm.

CO2 RF metal laser

CO2 RF metal laser tube (from Germany Rofin);

Power: 150 watt / 300 watt / 600 watt

Technical Specifications of the Laser Machine

| Model |

ZJ(3D)-15050LD |

| Laser source |

CO2 RF metal laser |

| Laser power |

150 watt / 300 watt / 600 watt |

| Working table |

Conveyor type |

| Table size |

1500mm×500mm |

| Processing area |

1500mm×1000mm |

| Power supply |

220V / 380V, 50/60Hz |

Laser Systems for Abrasive Industry

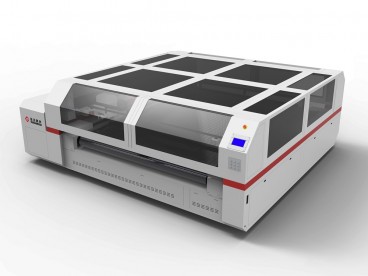

| Model NO. | Laser Systems | Functions |

| ZJ(3D)-15050LD | laser cutting and perforating machine | Cutting shapes and perforating micro-holes on sandpaper. Roll to roll processing. |

| JG-16080LD | cross-laser cutting machine | To cut rectangle across the width of the roll of sandpaper. |

Applicable Material: Sandpaper

Applicable Industry: Skateboard non-slip sanding grip tape, automotive, advertising, metal, constructions, accessories, etc.

Laser Perforating Sandpaper

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?