Laser finishing solutions for labels converting

The unique table size laser die cutter on the market at affordable price

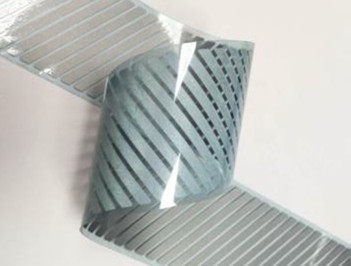

LC230 is a compact, economic and fully digital laser die cutter, available with Single or Dual Laser Heads. LC230 comes standard with unwinding, laser cutting, rewinding and waste matrix removal units. And it is prepared for add-on modules such as UV varnishing, lamination and slitting, etc.

The system can be fitted with barcode readers for automatic pattern changeover on the fly. Stackers or pick-and-place robots can be added for a fully automated solution.

LC230 offers completed digital and automatic solution for roll to roll (or roll to sheet) laser cutting. No extra tooling expense and waiting time needed, ultimate flexibility to fulfill dynamic market demands.

Benefits of Laser Die Cutter

The digital laser finisher “roll to roll” for laser cutting and converting.

Quick Turnover

Eliminates traditional tooling & die fabrication, maintenance and storage. Ideal solution for just-in-time manufacturing and short-runs.

Multiple Processes

Suitable for different kinds of work:

Full cutting, kiss-cutting, perforating, micro perforating, engraving, marking, creasing - in a single processing run.

Digital Workflow

A complete digital workflow solution:

Pattern changeover is as simple as opening a file; no downtime or setup is required.

Precision Cutting

Produce complex geometry and superior part quality that cannot be replicated in the traditional die cutting process.

Vision System - Cut to Print

Vision camera systems or sensors are available for registering printed materials or pre-die cut shapes, allowing precision cutting with cut-print registration of 0.1mm.

Intelligent Software

Self-developed software intelligent algorithms improve cutting accuracy by constantly adjusting the laser processing speed to match different graphics.

PC Workstation

Through the PC Workstation you can manage all the parameters of the laser station, optimize layout for maximum yields.

Modular Design

Extreme Flexibility: A variety of options are available to automate and customize the system to suit a wide variety of converting requirements.

Unlimited Cutting Path

The cutting beam can be moved in any direction and cuts smoothly. Easily create rounded, squared corners or jagged edges for shaped labels.

Modular Stations Provide Endless Versatility

• Slitting (Razor, Scissor & Score Cut)

• UV Varnishing

• Lamination

• Back Score (Slit) the Liner

• Automatic Web Guiding

• Liner Change Assembly (Top or Bottom)

• Barcode Reading - on-the-fly job change

• Matrix Removal

• Dual Rewinder

• Stacking Unit

• Sheeting Unit with Adjustable Conveyor Table

Main Technical Parameter of the LC230 Digital Laser Die Cutter

| Model No. |

LC230 |

| Max. cutting width |

230mm / 9" |

| Max. cutting length |

Unlimited |

| Max. width of feeding |

240mm / 9.4” |

| Max. web diameter |

400mm / 15.7" |

| Web speed |

0-60m/min (Speed varies depending on material and cutting pattern) |

| Accuracy |

±0.1mm |

| Laser type |

CO2 RF metal laser |

| Laser power |

100W / 150W / 300W |

| Power supply |

380V three phase 50/60Hz |

Loading the designs

Support .dxf, .dst, .jpg, .ai, .plt, .bmp. etc.

Parameter setting

Laser power, working speed, labaels quantily to cut, etc.

Start cutting

Computer automatically save the parameters for the same material and patterns

Watch Laser Die Cutting in Action!

Digital Laser Die Cutter for Labels 100 Watts LC230

Technical Parameters of Digital Laser Die Cutter LC230

| Main Technical Parameters |

| Working Area |

Width 230mm (9″), Length ∞ |

| Speed |

0-60m/min (depending on laser power and cut pattern) |

| Machine Dimension |

2400mm (L) X 730mm (W) X 1800mm (H) |

| Weight |

1500Kg |

| Consumption |

2KW |

| Power supply |

380V / 220V, 50Hz / 60Hz, three phase |

| Standard Configuration |

| Unwinder |

|

| Maximum Web Width |

240mm (9.4″) |

| Maximum Web Diameter |

400mm (15.7”) |

| Core |

3 inch |

| Pneumatic Expanding Shaft |

3 inch |

| Tension Control |

Optional |

| Splice Table |

Optional |

| Web Guide |

BST / EURDOW (Optional) |

| Laser System |

| Laser Source |

Sealed CO2 RF laser |

| Laser Power |

100W / 150W / 300W |

| Laser Wavelength |

10.6 micron or other |

| Laser Beam Positioning |

Galvanometer |

| Laser Spot Size |

210 microns |

| Cooling system |

Water cooling |

| Matrix Removal |

| Back side slitting |

|

| Matrix Rewinding |

|

| Pneumatic Expanding Shaft |

3 inch |

| Rewinder |

| Tension Control |

Optional |

| Pneumatic Expanding Shaft |

3 inch |

| Options |

| UV Varnishing unit |

|

| Laminating unit |

|

| Slitting unit |

|

*** Note: As products are constantly updated, please contact us for latest specifications. ***

Golden Laser’s Typical Models of Digital Laser Die Cutters

| Model No. |

LC230

|

LC350

|

| Max. cutting width |

230mm / 9″

|

350mm / 13.7″

|

| Web width |

240mm / 9.4”

|

370mm / 14.5″

|

| Maximum web diameter |

400mm / 15.7″

|

750mm / 29.5″

|

| Web speed |

0-60m/min

|

0-120m/min

|

|

(Speed varies depending on material and cutting pattern)

|

| Laser type |

CO2 RF metal laser

|

| Laser power |

100W / 150W / 300W

|

150W / 300W / 600W

|

| Dimensions |

2400mm (L) X 730mm (W) X 1800mm (H) |

3700mm (L) X 2000mm (W) X 1820mm (H)

|

| Weight |

1500Kg

|

3000Kg

|

| Standard function |

Full cutting, kiss cutting (half cutting), perforation, engraving, marking, etc. |

| Optional function |

Lamination, UV varnish, slitting, etc. |

| Processing materials |

PET, paper, glossy paper, matt paper, polyester, polypropylene, BOPP, plastic, film, polyimide, reflective tapes, fabric, sandpaper, etc. |

| Supported graphics formats |

AI, BMP, PLT, DXF, DST |

| Power supply |

380V 50HZ or 60HZ / Three phase |

Laser Converting Application

Common materials used for the laser die cutting machines include :

Paper, plastic film, glossy paper, matt paper, synthetic paper, cardboard, polyester, polypropylene (PP), PU, PET, BOPP, plastic, film, microfinishing film, etc.

Common applications for the laser die cutting machines include :

- Labels

- Adhesive Labels and Tapes

- Reflective Tapes / Retro Reflective films

- Industrial Tapes / 3M Tapes

- Decals / Stickers

- Abrasives

- Gaskets

Please contact Golden Laser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Roll-to-roll? Or sheetfed?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?