- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

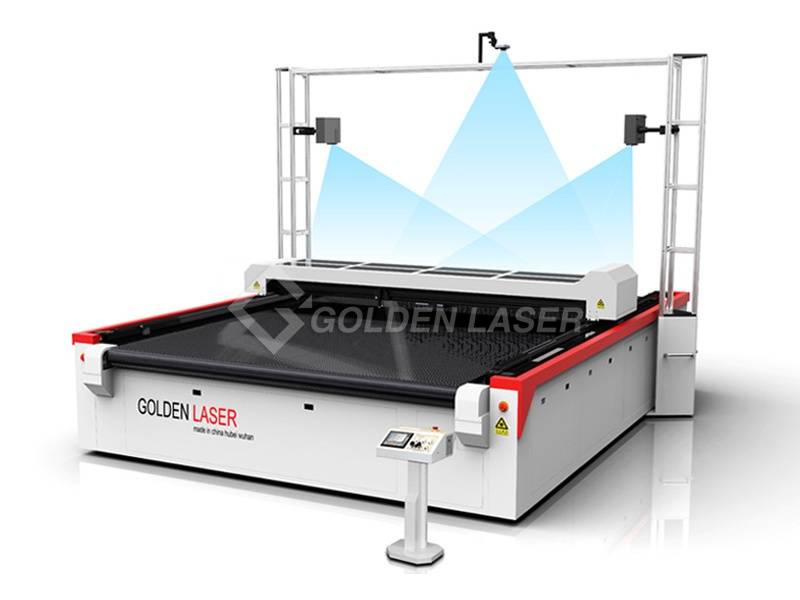

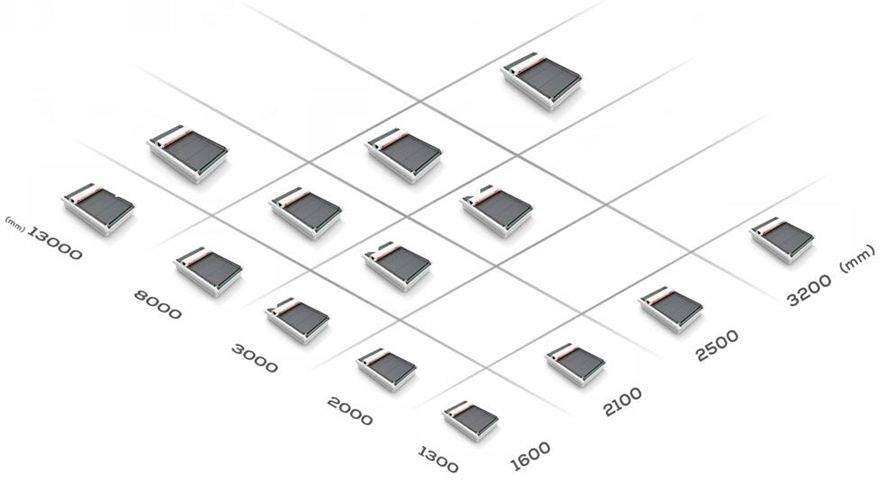

Genuine Leather Laser Cutting Machine

Model No.: CJG-160250LD

Introduction:

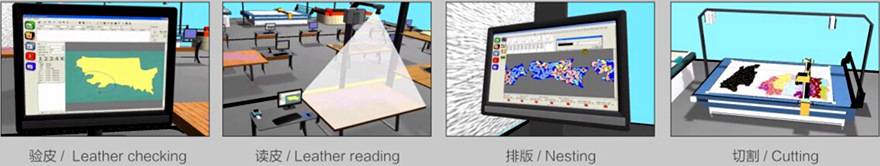

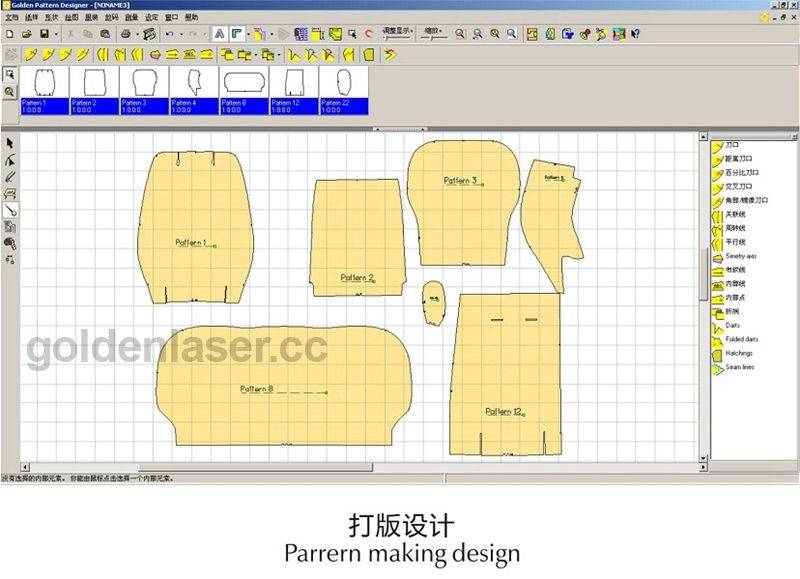

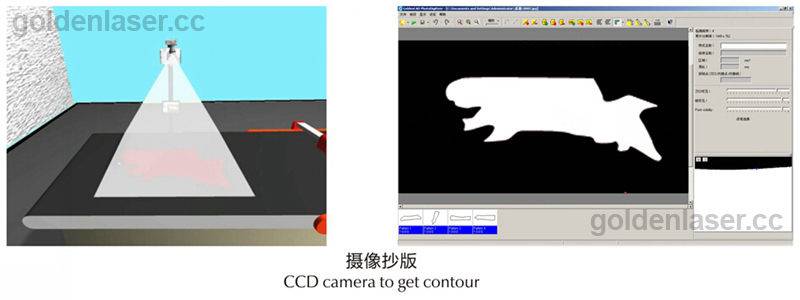

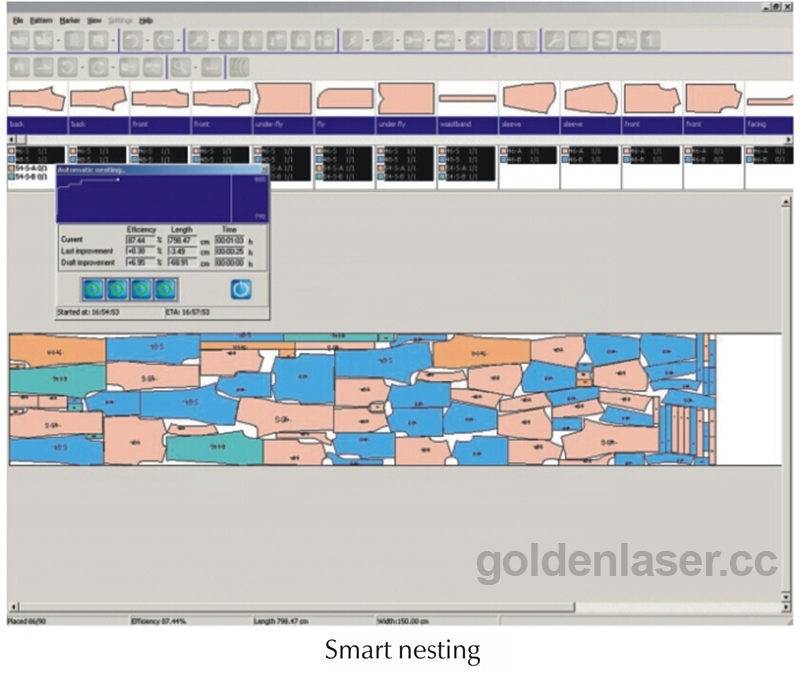

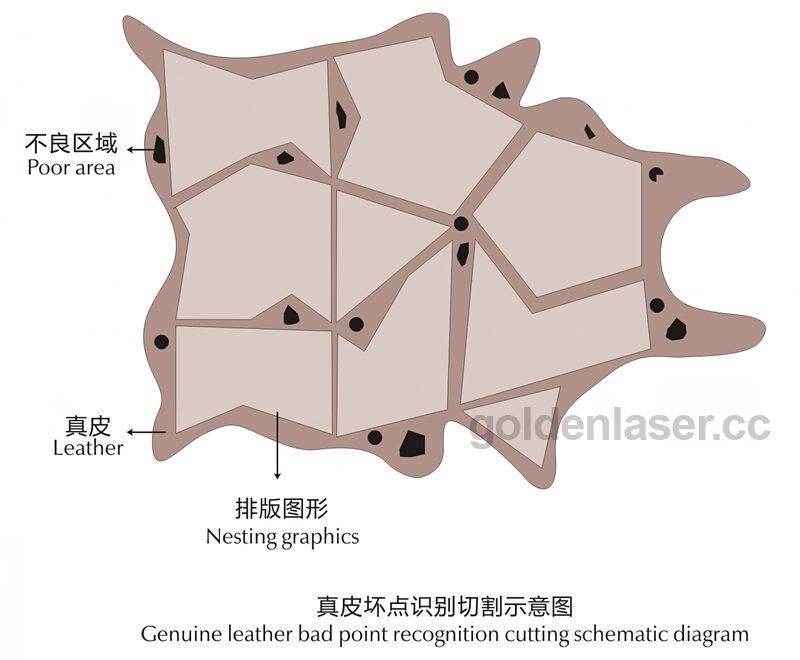

Laser cutting machine with camera and projector. For hides leather goods large format precision cutting. Simplify the complex processing of natural leather cutting to four steps: Inspection; Reading; Nesting; Cutting. High-precision digital camera system, accurately read the contour of leather and avoid poor area and do rapid automatic nesting on sample pieces. During the nesting, it can also project the same pieces, display sample cutting position on the leather and improve the utilization of leather.

Genuine Leather Laser Cutting Machine with Projector and Camera

Advantages

• No required mould, laser processing is flexible and convenient. After setup the pattern, laser can start to process.

• Smooth cutting edges. No mechanical stress, no deformation. Laser processing can save the cost of mold production and preparation time.

• Good cutting quality. Cutting precision can reach to 0.1mm. Without any graphic restrictions.

• It is a complete and practical set of genuine leather laser cutting system, with pattern digitizing, recognition system and nesting software. High degree of automation, improving efficiency and saving material.

Machine Features

• Especially for genuine leather cutting. Suitable for all kinds of genuine leather and hides products cutting processing industries.

• Laser cutting with smooth and precise cutting edge, high quality, no distortion.

• It adopts high-precision digital system that can accurately read the contour of leather and avoid poor area and do rapid automatic nesting on sample pieces (users can also use manually nesting).

Simplify the complex processing of genuine leather cutting to four steps:

1. Inspection 2. Reading 3. Nesting 4. Cutting

• During the time of nesting, it can also project the same pieces, display sample cutting position on the leather and improve the utilization of leather.

• Equipped with large area recognition system, projection system and auto-nesting software.

• It is applicable to car seat cover, sofa and other large-size leather goods precision cutting.