Jeans Laser Engraving Machine

Model No.: ZJ(3D)-9090LD

Introduction:

Denim jeans laser engraving is catering to the demands of replacing traditional washing processes. With 3D dynamic large-format galvanometer marking technology, this system is specifically developed for jeans, denim, garment engraving. Equipped with circulation type material feeding processing technology, the system engraves patterns on specified positions during the process. Thereafter, the material automatically moves to the engraving area with the help of a conveyor.

Jeans Laser Engraving Machine

ZJ(3D)-9090LD

Features of Jeans Laser Engraving System

• This laser system is specially designed for Denim Jeans engraving, successfully replaced traditional processing. energy-saving, eco-friendly, no pollution and strong personalized.

• Circulating convey processing. While in the process, at the same time it also can load material with high productivity.

• This machine is equipped with CO2 RF metal laser and triaxial dynamic large-format galvanometer control system, Low maintenance cost. Fully closed structure. Smoking effect is good. Safe and reliable system.

• It can engrave a variety of personalized designs such as cat whiskers, monkey wash, PP spray, hanging rub, ripped, sandblasting, snow, portrait and other effects with clear texture and never fade.

Highlights of Jeans Laser Engraving System

- Especially suitable for Denim Jeans laser wash processing

- Projection positioning engraving parts, processing more accurate

- Multi-station circulating conveyor, precisely aligning and feeding

- Working Area:900X900mm / 1200X1200mm

- 600 watt / 300 watt CO2 RF metal laser tube

- 3D dynamic large-format galvanometer marking technology

- Energy saving

- Low maintenance

- Hermetic structure

- Low contamination

- Excellent suction effect

- High working efficiency

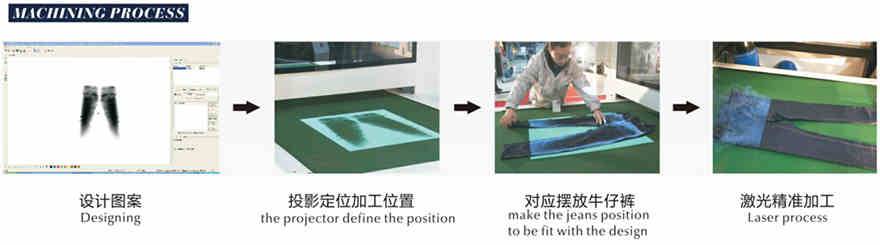

Jeans Laser Engraving Processing Flow

Jeans Laser Engraving Machine Working Scene

| ZJ(3D)-9090LD Denim Jeans Laser Engraving Machine | |||

| Laser Generator and Optic parameters | |||

| Laser Type | CO2 RF metal laser | Laser Power | 600W / 300W |

| Laser Wavelength | 10.6 micro meters | Galvo effective area | 900mmX900mm |

| Galvo process speed | 0-20000mm/s (defined as the process material and requirement) | ||

| Software system | |||

| Control software | Goldenlaser original software | ||

| Software Format | BMP, AI, DST, DXF, PLT, etc. | ||

| Working table parameter | |||

| Working table type | Transport rubber conveyer belt | ||

| Extend feed table area | 1100mm width X 1500mm length | Conveyor speed | 0-600mm/s |

| Assistant System | |||

| Protection System | Full protection with optic part structure | ||

| Control System | GoldenLaser III control card | ||

| Cooling System | Constant temperature water chiller 5KW for laser machine | ||

| Exhaust System | Fixed Upper exhaust fans / Air blow fans | ||

→ General Type Laser Engraving System for Denim Jeans ZJ (3D) -9090TB

→ Affordable Type Laser Engraving System for Denim Jeans ZJ (3D) -15075TB

→ Roll to roll Denim Engraving Laser System ZJ (3D) -160LD

Jeans Laser Engraving Machine Application and Industry

Digital laser processing replaced the traditional Jeans production process of hand brush, sandblasting, whisker, monkey wash, PP spray, hanging rub, ripped, etc. Shorten the process, enhance the added value. Very suitable for denim garment factories, washing laundry, washing and dyeing factories and personalized fashion denim deep processing.

<< More Samples of Denim Jeans laser engraving

Eight Reasons for Choosing Golden Laser – Denim Jeans Laser Engraving Machine

1. Simple Processing, Saving Labor

Laser engraving adopts automatic motion control system and laser non-contact and heat processing principle. Software produces fading, sand blasting, 3D cat whiskers, tattered and other effects instead of the traditional process of “hand brush”. Compared jeans cat whiskers, monkeys, tattered, worn of traditional tedious manual process, Laser engraving only needs to import the designed graphics and multiple processes can be done in one step, more efficient, and can save a lot of labor costs.

2. Conformity, Low Rejection Rate

Just set up the best laser engraving process parameters, to ensure the conformity of the effect of all finished products, avoiding the quality differences of traditional manual processing

3. Personalized Value-Added

Compared to traditional manual processing can only process simple graphics, laser engraving can produce a clear artistic pattern on denim fabric. These patterns may include text, numbers, logos, images. Precise laser engraving process can also present monkeys, whiskers, worn, washing and other effects. Jeans laser engraved graphics without any restrictions, can easily combine with fashion elements to enhance the broad personalized value-added space.

4. Environmentally Friendly

Processing mainly by means of optical, mechanical and electrical, denim laser process completely abandoned all kinds of high pollution sources, such as sand blasting, oxidation, printing and dyeing, which can protect environment by the greatest extent.

5. Wide Range of Application

After many years of accumulated technology and application development, Golden Laser has been developed for multi-platform full range of denim laser engraving equipment. Customers can equip with the most suitable products according to their own needs and processing scale to create the highest profit.

6. Competitive Price

Golden Laser has 14 years of experience in the textile and apparel industry and established healthy patterns of new product development, control costs and more benefits back to customers.

7. Service

Golden Laser has professional sales team, consultant team, and after-sale service team that could ensure customers impeccable service on site as well as remote service over phone or internet video.

8. Win-Win Cooperation

Golden Laser can help business partners set up a joint laboratory to explore creative products and win a position in denim processing market. Reduce investment risk and accelerate transformation of traditional denim enterprise.