Dual Function Fiber Laser Sheet & Tube Cutting Machine

Available for cutting various diameters of tubes and sizes of sheets on one machine.

Cutting tube length 3m, 4m, 6m, diameter from 20-300mm; cutting sheet size 1.5×3m, 1.5×4m, 1.5×6m, 2×4m, 2×6m

Open design for easy loading and unloading.

Single working table, saving space.

Integrated design provides dual cutting functions for metal sheet and tube.

Drawer style tray makes easy collecting and cleaning for the small parts and scraps.

Gantry double driving structure, high damping bed, good rigidity, high speed and acceleration.

The world’s leading fiber laser resonator and electronic components to ensure machine superior stability.

The advantages of fiber laser cutting machine

Low power consumption

Power consumption of fiber laser is only 20%~30% of CO2 laser. The increased electrical efficiency of fiber laser greatly reduces the power consumption of the fiber laser system, saving electricity costs and reducing the initial investment in electrical equipment.

Fast Speed

The efficiency of a fiber laser far exceeds YAG or CO2 laser. Fiber laser cutting of thin metal is double faster than YAG or CO2 laser cutting: carbon steel and stainless steel up to 8 mm (0.31") are metals that typically benefit from fiber laser technology.

Maintenance free

The projected lifetimes of fiber laser is greater than 100,000 hours of continuous or pulsed operation. Fiber laser does not require routine maintenance. No laser gas is required. The laser beam quality is stable over time and is immediately available at startup.

Easy to cut reflective metals

The fiber laser beam is capable of cutting reflective metals with much less energy as the laser is absorbed into the metal being cut. Copper, brass, aluminum and galvanized steel can be easily cut by fiber lasers, besides mild steel and stainless steel.

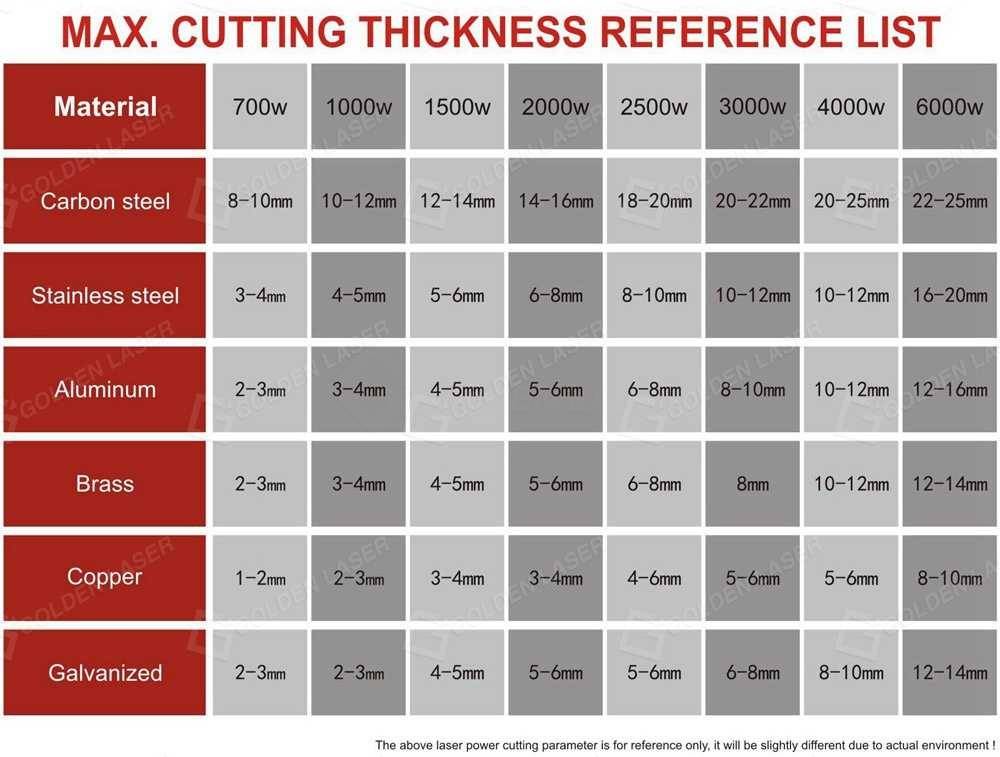

Maximum cutting thickness for different laser powers

Dual CNC Fiber Laser Sheet Metal and Tube / Pipe Cutting Machine

Technical Parameter

|

Model No.

|

GF-1530T

|

|

Laser type

|

Fiber laser (nLight / IPG)

|

|

Laser wavelength

|

1070nm

|

|

Laser power output rating

|

700W 1000W 1200W 1500W 2000W 2500W 3000W

|

|

Working table

|

Fixed working table

|

|

Working area for sheet processing (L×W)

|

1500mm×3000mm

|

|

Pipe/Tube processing (L×Φ)

|

L3000mm, Φ20~200mm

(Φ20~300mm for option)

|

|

Positioning accuracy X, Y and Z axle

|

±0.03mm/m

|

|

Repeat positioning accuracy X, Y and Z axle

|

±0.02mm

|

|

Maximum positioning speed of X and Y axle

|

72m/min

|

|

Acceleration

|

1g

|

|

Control system

|

CYPCUT

|

|

Format supported

|

AI, BMP, PLT, DXF, DST, etc.

|

|

Power supply

|

AC220V 50/60Hz / AC380V 50/60Hz

|

|

Total power consumption

|

12KW

|

|

Floor space

|

4.5mtr x 3.2mtr (GF-1530 fixed table)

|

Main Components and Parts

|

Article Name

|

Qty

|

Origin

|

|

Fiber laser generator

|

1 set

|

nLight / IPG

|

|

Focus lens

|

1 pc

|

ⅡⅥ USA

|

|

Servo motor and driver

|

4 sets

|

YASKAWA (Japan)

|

|

Rack and pinion

|

1 set

|

YYC

|

|

Dynamic focus laser head

|

1 set

|

Raytools (Switherland)

|

|

Control system

|

1 set

|

Cypcut

|

|

Liner guide

|

1 set

|

HIWIN

|

|

Automatic lubricating system

|

1 set

|

Golden Laser

|

|

Water chiller

|

1 set

|

Golden Laser

|

|

Proportional valve

|

1 set

|

SMC (Japan)

|

|

Dual (sheet & tube) Fiber Laser Cutting Machines Optional Models

|

|

Model

|

GF-1540T

|

GF-1560T

|

GF-2040T

|

GF-2060T

|

|

Cut area

|

1.5×4m

|

1.5×6m

|

2×4m

|

2×6m

|

|

Tube length

|

4m

|

6m

|

4m

|

6m

|

|

Laser source

|

IPG/N-light fiber laser resonator

|

|

Laser source power

|

700W ~ 4KW

|

GOLDEN LASER – FIBER LASER CUTTING SYSTEMS SERIES

|

Automatic Bundle Loader Tube Laser Cutting Machine

|

|

Model NO.

|

P2060A

|

P3080A

|

|

Pipe Length

|

6m

|

8m

|

|

Pipe Diameter

|

20mm-200mm

|

20mm-300mm

|

|

Laser Power

|

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W

|

|

Fiber Laser Tube Cutting Machine

|

|

Model NO.

|

P2060

|

P3080

|

|

Pipe Length

|

6m

|

8m

|

|

Pipe Diameter

|

20mm-200mm

|

20mm-300mm

|

|

Laser Power

|

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W

|

|

Heavy Duty Pipe Laser Cutting Machine

|

|

Model NO.

|

P30120

|

|

Pipe Length

|

12mm

|

|

Pipe Diameter

|

30mm-300mm

|

|

Laser Power

|

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W

|

|

Full Closed Fiber Laser Cutting Machine with Pallet Exchange Table

|

|

Model NO.

|

Laser Power

|

Cutting Area

|

|

GF-1530JH

|

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W / 8000W

|

1500mm×3000mm

|

|

GF-2040JH

|

2000mm×4000mm

|

|

GF-2060JH

|

2000mm×6000mm

|

|

GF-2580JH

|

2500mm×8000mm

|

|

Open Type Fiber Laser Cutting Machine

|

|

Model NO.

|

Laser Power

|

Cutting Area

|

|

GF-1530

|

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W

|

1500mm×3000mm

|

|

GF-1560

|

1500mm×6000mm

|

|

GF-2040

|

2000mm×4000mm

|

|

GF-2060

|

2000mm×6000mm

|

|

Dual Function Fiber Laser Metal Sheet & Tube Cutting Machine

|

|

Model NO.

|

Laser Power

|

Cutting Area

|

|

GF-1530T

|

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W

|

1500mm×3000mm

|

|

GF-1560T

|

1500mm×6000mm

|

|

GF-2040T

|

2000mm×4000mm

|

|

GF-2060T

|

2000mm×6000mm

|

|

High Precision Linear Motor Fiber Laser Cutting Machine

|

|

Model NO.

|

Laser Power

|

Cutting Area

|

|

GF-6060

|

700W / 1000W / 1200W / 1500W

|

600mm×600mm

|

Application industry

Sheet metal fabrication, hardware, kitchenware, electronic, automotive parts, advertising, craft, lighting, decoration, jewelry, glasses, elevator panel, furniture, medical device, fitness equipment, oil exploration, display shelf, agriculture and forestry machinery, food machinery, bridge, ship, aerospace, structure parts, etc.

Applicable material

Carbon steel, stainless steel, galvanized sheet, alloy, titanium, aluminum, brass, copper and other metal plates and pipes.

Fiber Laser Cutting Metal Sheet and Tube Samples Demonstration

<< Read more about fiber laser metal cutting samples

Fiber Laser Cutting Metal Thickness for Different Laser Powers

|

Laser Power

|

700W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

8mm

|

10mm

|

O2

|

|

Stainless Steel

|

3mm

|

4mm

|

N2

|

|

Aluminum

|

2mm

|

3mm

|

Air

|

|

Brass

|

2mm

|

3mm

|

N2

|

|

Copper

|

1mm

|

2mm

|

O2

|

|

Galvanized Steel

|

2mm

|

3mm

|

N2

|

|

Laser Power

|

1000W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

10mm

|

12mm

|

O2

|

|

Stainless Steel

|

4mm

|

5mm

|

N2

|

|

Aluminum

|

3mm

|

4mm

|

Air

|

|

Brass

|

3mm

|

4mm

|

N2

|

|

Copper

|

2mm

|

3mm

|

O2

|

|

Galvanized Steel

|

2mm

|

3mm

|

N2

|

|

Laser Power

|

1200W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

12mm

|

14mm

|

O2

|

|

Stainless Steel

|

5mm

|

6mm

|

N2

|

|

Aluminum

|

3mm

|

4mm

|

Air

|

|

Brass

|

3mm

|

4mm

|

N2

|

|

Copper

|

2mm

|

3mm

|

O2

|

|

Galvanized Steel

|

3mm

|

4mm

|

N2

|

|

Laser Power

|

1500W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

12mm

|

14mm

|

O2

|

|

Stainless Steel

|

5mm

|

6mm

|

N2

|

|

Aluminum

|

4mm

|

5mm

|

Air

|

|

Brass

|

4mm

|

5mm

|

N2

|

|

Copper

|

3mm

|

4mm

|

O2

|

|

Galvanized Steel

|

4mm

|

5mm

|

N2

|

|

Laser Power

|

2000W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

14mm

|

16mm

|

O2

|

|

Stainless Steel

|

6mm

|

8mm

|

N2

|

|

Aluminum

|

5mm

|

6mm

|

Air

|

|

Brass

|

5mm

|

6mm

|

N2

|

|

Copper

|

3mm

|

4mm

|

O2

|

|

Galvanized Steel

|

5mm

|

6mm

|

N2

|

|

Laser Power

|

2500W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

18mm

|

20mm

|

O2

|

|

Stainless Steel

|

8mm

|

10mm

|

N2

|

|

Aluminum

|

6mm

|

8mm

|

Air

|

|

Brass

|

6mm

|

8mm

|

N2

|

|

Copper

|

4mm

|

6mm

|

O2

|

|

Galvanized Steel

|

5mm

|

6mm

|

N2

|

|

Laser Power

|

3000W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

20mm

|

22mm

|

O2

|

|

Stainless Steel

|

10mm

|

12mm

|

N2

|

|

Aluminum

|

8mm

|

10mm

|

Air

|

|

Brass

|

8mm

|

8mm

|

N2

|

|

Copper

|

5mm

|

6mm

|

O2

|

|

Galvanized Steel

|

6mm

|

8mm

|

N2

|

|

Laser Power

|

4000W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

20mm

|

25mm

|

O2

|

|

Stainless Steel

|

10mm

|

12mm

|

N2

|

|

Aluminum

|

10mm

|

12mm

|

Air

|

|

Brass

|

10mm

|

12mm

|

N2

|

|

Copper

|

5mm

|

6mm

|

O2

|

|

Galvanized Steel

|

8mm

|

10mm

|

N2

|

|

Laser Power

|

6000W

|

|

Material

|

Clean Cut

|

Cutting Limit

|

Gas

|

|

Mild Steel

|

22mm

|

25mm

|

O2

|

|

Stainless Steel

|

16mm

|

20mm

|

N2

|

|

Aluminum

|

12mm

|

16mm

|

Air

|

|

Brass

|

12mm

|

14mm

|

N2

|

|

Copper

|

8mm

|

10mm

|

O2

|

|

Galvanized Steel

|

12mm

|

14mm

|

N2

|

Please contact Golden Laser for more specification and quotation about fiber laser cutting machine. Your response of following questions will help us recommend the most suitable machine.

1. What type of metal do you need to cut? Metal sheet or tube? Carbon steel or stainless steel or aluminum or galvanized steel or brass or copper …?

2. If cutting sheet metal, what is the thickness? What working size do you need? If cutting metal tube or pipe, what is wall thickness, diameter and length of the pipe / tube?

3. What is your finished product? What is your application industry?

4. Your name, company name, email, telephone (WhatsApp) and website?