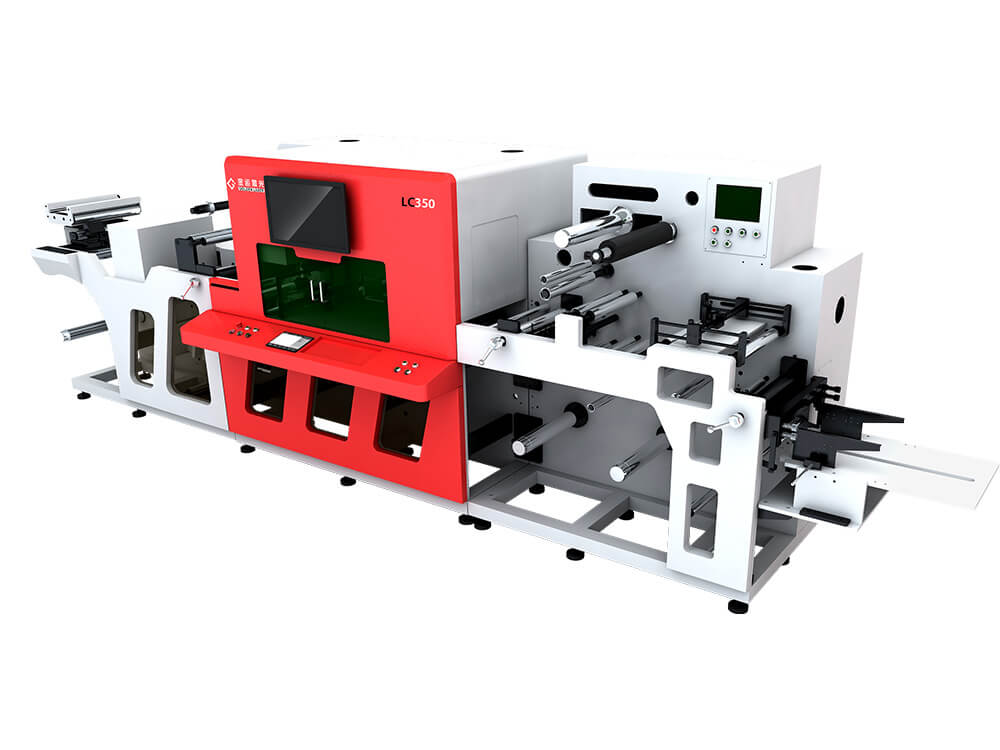

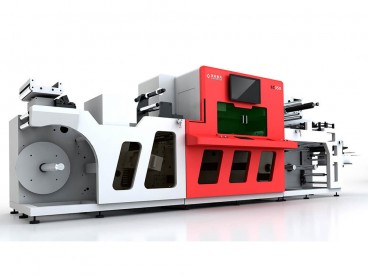

Label Laser Die Cutting Machine LC350

Model No.: LC350

Introduction:

Fully digital, high speed and automatic laser die-cutting and finishing system with roll-to-roll, roll-to-sheet and roll-to-sticker applications.

LC350 laser cutting system delivers high quality, on-demand converting of roll materials, dramatically reducing lead time and eliminating the costs of conventional die cutting through a complete, efficient digital workflow.

- Maximum Web Width : 350mm / 13.7”

- Maximum Web Diameter : 750mm / 23.6”

- Maximum Web Speed : 120m/min

- Laser Power : 150 Watt / 300 Watt / 600 Watt

LC350 Laser Die Cutting Machine is a fully digital laser finishing machine with dual-station lasers. The standard version features unwinding, laser cutting, dual rewinding and waste matrix removal. And it is prepared for add-on modules such as varnishing, lamination, slitting and sheeting, etc. It is possible to cut with different power levels on the same label.

The system can be fitted with Barcode (or QR Code) reader for continuously cutting and seamlessly adjust jobs on the fly. LC350 offers completed digital and automatic solution for roll to roll (or roll to sheet, roll to part) laser cutting. No extra tooling expense and waiting time needed, ultimate flexibility to fulfill dynamic market demands.

Key Features of LC350 Laser Die Cutting Machine

The digital laser finisher “roll to roll” for laser cutting and converting.

Quick Specifications

Main Technical Parameter of the LC350 Digital Laser Die Cutter

| Model No. | LC350 |

| Max. Web Width | 350mm / 13.7” |

| Max. Width of Feeding | 750mm / 23.6” |

| Max. Web Diameter | 400mm / 15.7" |

| Max. Web Speed | 120m/min (depending on laser power, material and cut pattern) |

| Accuracy | ±0.1mm |

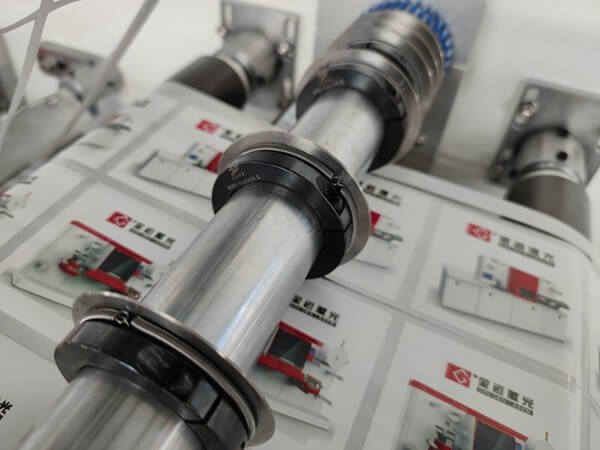

| Laser Type | CO2 RF metal laser |

| Laser Power | 150W / 300W / 600W |

| Laser Beam Positioning | Galvanometer |

| Power Supply | 380V three phase 50/60Hz |

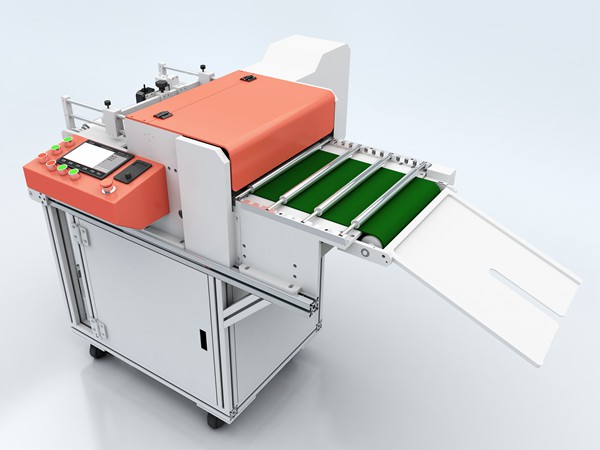

Converting Options of LC350 Laser Die Cutting Machine

Goldenlaser is capable of customizing laser die cutting machines to adapt your specific needs by adding the converting modules. Your new or current production lines may benefit from the following converting options.

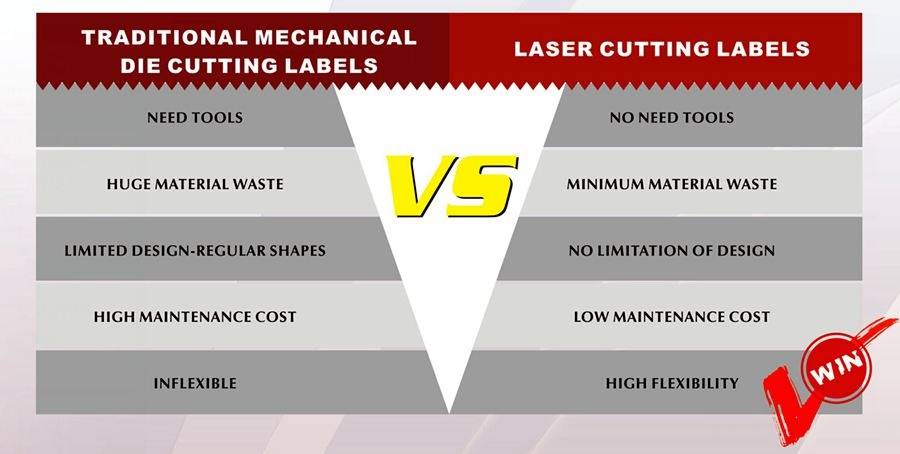

What are the benefits of laser die cutter for labels?

Quick Turnaround

No need dies, you can laser cut your designs anytime you want. Never waiting for a new die to be delivered from the manufacturer.

Fast Cutting

Cutting speed up to 2000mm/second, web speed up to 120 meters/min.

Automation and Easy Operation

CAM/CAD Computer control only need input cutting file in software. Instantly change cutting shapes on the fly.

Flexible and Versatile

Full Cutting, kiss cutting (half cutting), perforating, engraving, and marking, multiple functions.

Slitting, lamination, UV varnishing, and more optional functions to meet customer individual needs.

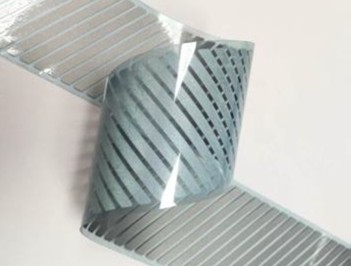

This laser die cutter not only can cut printed label rolls, but also can cut plain label rolls, reflective materials, adhesive labels, double-sided & single-sided tapes, special-material labels, industrial tapes and so on.

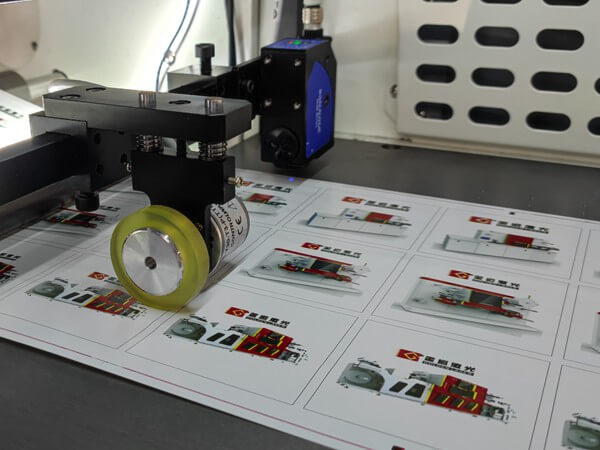

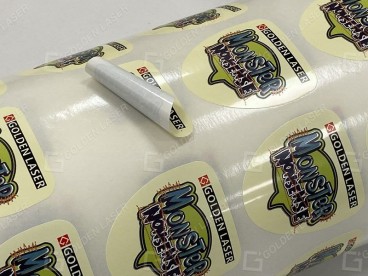

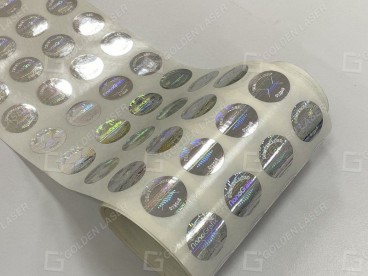

Laser Cutting Samples

Watch Laser Die Cutting in Action!

Digital Laser Die Cutter for Labels with Flexo Unit, Lamination and Slitting

Technical Parameters of LC350 Laser Die Cutting Machine

| Max Cutting Width | 350mm / 13.7” |

| Max Width of Feeding | 370mm / 14.5” |

| Max Web Diameter | 750mm / 29.5” |

| Max Web Speed | 120m/min (Depending on laser power, material and cut pattern) |

| Accuracy | ±0.1mm |

| Laser Type | CO2 RF laser |

| Laser Beam Positioning | Galvanometer |

| Laser Power | 150W / 300W / 600W |

| Laser Power Output Range | 5%-100% |

| Power Supply | 380V 50Hz / 60Hz, Three phase |

| Dimensions | L3700 x W2000 x H 1820 (mm) |

| Weight | 3500KG |

*** Note: As products are constantly updated, please contact us for latest specifications. ***

Goldenlaser’s Typical Models of Digital Laser Die Cutting Machines

| Model No. |

LC350 |

LC230 |

| Max Cutting Width |

350mm / 13.7” |

230mm / 9” |

| Max Width of Feeding |

370mm / 14.5” |

240mm / 9.4” |

| Max Web Diameter |

750mm / 29.5” |

400mm / 15.7 |

| Max Web Speed |

120m/min |

60m/min |

|

(Depending on laser power, material and cut pattern) |

||

| Accuracy |

±0.1mm |

|

| Laser Type |

CO2 RF laser |

|

| Laser Beam Positioning |

Galvanometer |

|

| Laser Power |

150W / 300W / 600W |

100W / 150W / 300W |

| Laser Power Output Range |

5%-100% |

|

| Power Supply |

380V 50Hz / 60Hz, Three phase |

|

| Dimensions |

L3700 x W2000 x H 1820 (mm) |

L2400 x W1800 x H 1800 (mm) |

| Weight |

3500KG |

1500KG |

Laser Converting Application

Common materials used for the laser die cutting machines include :

Paper, plastic film, glossy paper, matt paper, synthetic paper, cardboard, polyester, polypropylene (PP), PU, PET, BOPP, plastic, film, microfinishing film, heat transfer vinyl, reflective film, lapping film, double-sided tape, 3M VHB tape, reflex tape, fabric, Mylar stencils, etc.

Common applications for the laser die cutting machines include :

- Labels

- Printing & Packaging

- Adhesive Labels and Tapes

- Reflective Tapes / Retro Reflective films

- Industrial Tapes / 3M Tapes

- Decals / Stickers

- Abrasives

- Gaskets

- Automotive

- Electronics

- Stencils

- Twills, patches and embellishments for apparel

Laser UNIQUE Advantages for Adhesive Stickers and Labels Cutting

| - Stability and Reliability |

| Sealed Co2 RF laser source, the quality of cut is always perfect and constant over time with low cost of maintenance. |

| - High Speed |

| The Galvanometric system allows the bean to move very quickly, perfectly focalized on the entire working area. |

| - High Precision |

| The innovative Label Positioning System controls the web position on the X and Y axis. This device guarantees a cutting precision within 20 micron even cutting labels with an irregular gap. |

| - Extremely Versatile |

| The machine is very appreciated by label producers as it can create a huge variety of labels, in a single high speed process. |

| - Suitable to work a wide range of material |

| Glossy paper, matt paper, cardboard, polyester, polypropylene, polyimide, polymeric film synthetic, etc. |

| - Suitable for different kinds of work |

| Die cutting any kind of shape – cutting and kiss cutting – perforating – micro perforating – engraving |

| - No limitation of cutting design |

| You can cut different design with laser machine, no matter the shape or the size |

| -Minimal Material Waste |

| Laser cutting is non-contact heat process. tt is with slim laser beam. It will not cause any waste about your materials. |

| -Save your production cost & maintenance cost |

| Laser cutting no need mold/knife, no need to make mold for different design. Laser cut will save you a lot of production cost; and laser machine has long using life, without mold replacement cost. |

<< Read More about Roll to Roll Label Laser Cutting Solution