- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

Laser Cutter for Knitting Vamp, Mesh Fabric Sports Shoe Upper

Model No.: QZDMJG-160100LD

Introduction:

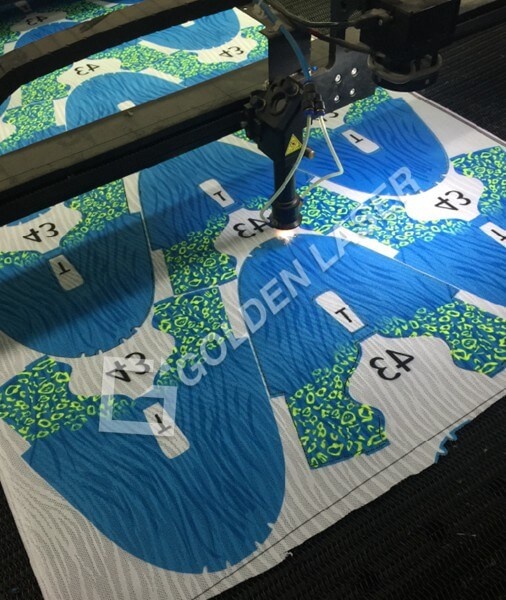

With one HD Camera equipped, the laser system can take photos of the digital printed, knitted, embroidered patterns, recognize the contour of patterns and then give cutting instruction for laser head to execute. The double-laser-head option makes this laser cutter implement high cutting efficiency.

- Laser Type : CO2 glass laser tube

- Laser Power : 80W / 130W / 150W

- Cutting Area : 1600mm×1000mm (63in×39.4in)

- Scan Area : 1500mm×900mm (59in×35.4in)

QZDMJG-160100LD

Versatile Smart Vision Laser Cutting System

Laser Cutting Fly Knitting Vamp Shoe Upper

Knitting Vamp Laser Cutting Workflow

Camera takes photo and extract outline

Automatic match + manual adjustment

Send process order to laser cutter to finish cutting

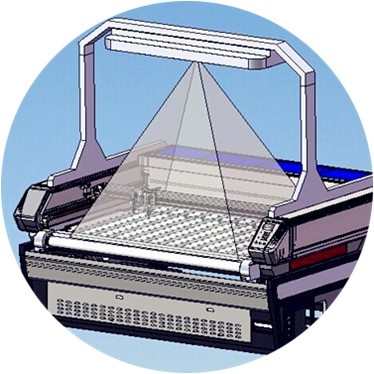

QZDMJG-160100LD is a powerful laser cutting machine with camera.

With one 18-million Pixel DSLR Canon Camera equipped, the laser system can take photos of the digital printed or embroidered patterns, recognize the contour of patterns and then give cutting instruction for laser head to execute.

The two-laser-heads option makes this laser cutter machine implement high cutting efficiency as well.

Highlights of the Smart Vision Laser Cutting System

High resolution camera positioning

- To capture pictures clearer

- Camera shooting the whole format, avoiding splicing graphics

- Supporting higher pixel camera optional

The fifth-generation vision recognition software

- High precision edge-seeking processing mode

- Multi-template processing mode

- Graphics can be partial or total modification

Automatic laser cutting

- With automatic feeder

- Automated continuous processing

- A variety of processing format optional

User-friendly operation system

- Real-time observation machining path

- Quick alignment processing the products that are unable to identify manually

- Using Internet technology to set up centralized control center, to achieve unmanned laser processing plant

Smart Vision System

No limitation of graphic sizes or templates. One time image acquisition by camera, any complex graphics can be precisely cut with the laser system.

Through high precision camera one time imaging for the full format material, this system can directly extract patterns contour and automatic cut. Or using registration marks to achieve aligning and cutting according to the original design. It supports real-time modification in the processing.

Camera

• CANON 18-megapixel high-resolution SLR camera

• 24 million pixel camera for option

• The recognition format can reach 1500 × 900mm. Compared with CCD system, graphics do not need to be spliced, and the recognition accuracy is higher.

• The camera is installed on the top of laser machine. Compared with CCD camera, the recognition format is larger and the laser head processing efficiency is higher.

Software

• It can directly catch outline of the pattern and edge-following cutting

• Compatible with the fifth generation CCD vision template cutting function

• The outlines of the object could display above its corresponding image after matching, convenient for judging the precision directly

• Continuously recognizing, feeding and cutting

• High working efficiency: All different patterns only one time catching.

Laser Cutting Samples