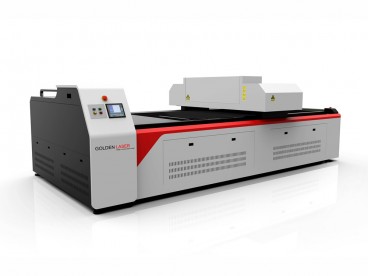

Laser Cutting Engraving Machine with Electric Lift Table

Model No.: MJG-13090SG

Introduction:

- 1300mm×900mm (51”×35”) table dimensions

- Motorized lifting worktable. Lift table goes up to 150mm (6″)

- CO2 glass laser tube 80 watts ~ 150 watts

- Honeycomb table and knife table options

- Chiller, compressor & exhaust fan included

JG13090SG is a cost-effective CO2 laser cutter and engraver that comes packed with user-friendly features to make operation a breeze.

JG13090SG comes with a specialized linear guide rail system for increased accuracy and longevity, an automatic focusing head and more. With a 150W laser tube packed inside, this machine has no trouble with thick acrylic, MDF or other materials.

Machine Features

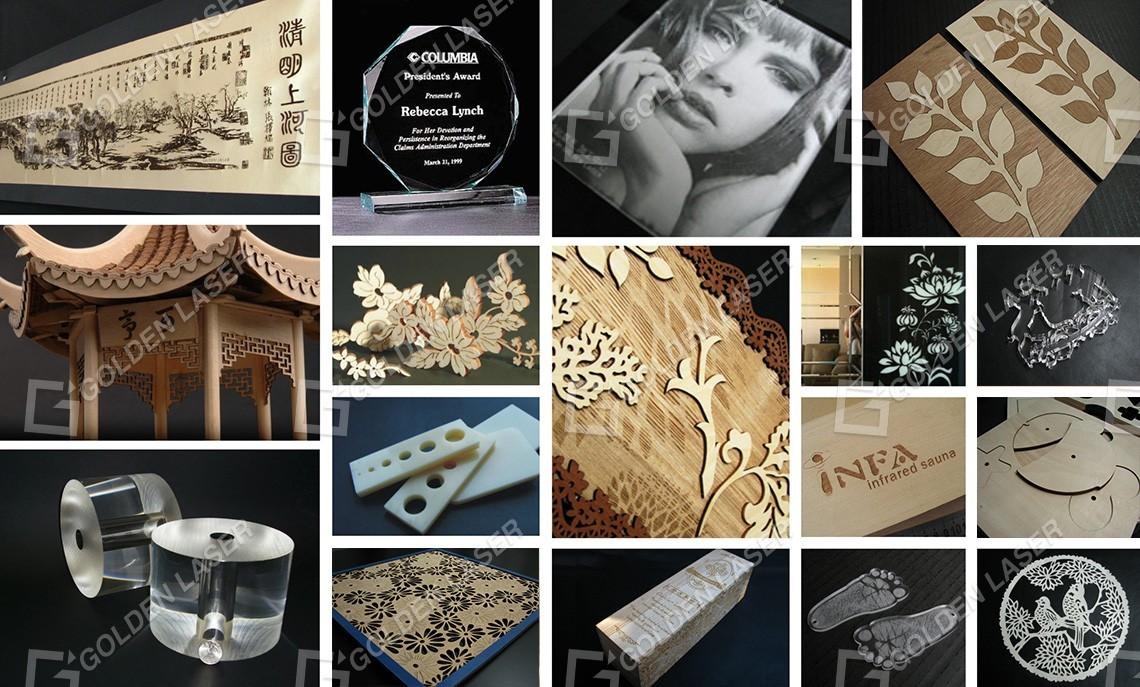

Application Industry

Suitable for acrylic, wood, balsa, plywood, veneer, cardboard, paper, plastic, leather, rubber, foam, EVA and other non-metal materials.

Applicable to advertising, crafts, models, decoration, furniture, packaging industry, etc.

Technical Parameters of CO2 Laser Cutting Engraving Machine JG-13090SG

| Model No. | JG-13090SG |

| Laser type | CO2 DC glass laser tube |

| Laser power | 80W / 110W / 130W / 150W / 300W |

| Working area | 1300mm×900mm (51.1”×35.4”) |

| Working table | Honeycomb working table / knife working table |

| Worktable electric lifting range: 0 – 150mm | |

| Cutting Speed | 0 – 24,000mm/min |

| Positioning accuracy | ±0.1mm |

| Motion system | Step motor |

| Cooling system | Constant temperature water chiller |

| Exhaust system | 550W or 1100W Exhaust fan |

| Air blower | Mini air compressor |

| Power supply | AC220V±5% 50 / 60Hz |

| Graphic Format Supported | PLT, DXF, AI, BMP, DST, etc. |

| External dimensions | 2150mm×1930mm×1230mm |

| Net weight | 500Kg |

| Options | Auto focus system, rotary engraving device, Servo motor |

Goldenlaser MARS Series CO2 Laser Systems Summary

Ⅰ. Laser Cutting Engraving Machine with Table Lifting System

| Model No. |

Laser head |

Working area |

| JG-10060SG |

One head |

1000mm×600mm |

| JG-13090SG |

1300mm×900mm |

Ⅱ. Laser Cutting Engraving Machine with Honeycomb Working Table

| Model No. |

Laser head |

Working area |

| JG-10060 |

One head |

1000mm×600mm |

| JG-13070 |

One head |

1300mm×700mm |

| JGHY-12570 II |

Dual head |

1250mm×700mm |

| JG-13090 |

One head |

1300mm×900mm |

| MJG-14090 |

One head |

1400mm×900mm |

| MJGHY-14090 II |

Dual head |

|

| MJG-160100 |

One head |

1600mm×1000mm |

| MJGHY-160100 II |

Dual head |

|

| MJG-180100 |

One head |

1800mm×1000mm |

| MJGHY-180100 II |

Dual head |

Ⅲ . Laser Cutting Machine with Conveyor Belt

| Model No. |

Laser head |

Working area |

| MJG-160100LD |

One head |

1600mm×1000mm |

| MJGHY-160100LD II |

Dual head |

|

| MJG-14090LD |

One head |

1400mm×900mm |

| MJGHY-14090D II |

Dual head |

|

| MJG-180100LD |

One head |

1800mm×1000mm |

| MJGHY-180100 II |

Dual head |

|

| JGHY-16580 IV |

Four head |

1650mm×800mm |

Applicable Materials and Industry

Suitable for acrylic, wood, double color plates and other non-metal materials.

Applicable to advertising, crafts, models, decoration, furniture, etc.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?