Laser Cutting Machine for Tent, Awning, Marquee, Canopy

Model No.: CJG-320500LD

Introduction:

Over-large format flatbed CO2 laser cutting machine. Designed for tent, awning, marquee, canopy, sunshade, paraglider, parachute, sailing cloth, inflatable castle materials cutting. Suitable for cutting nylon, polyester, canvas, polyamide, polypropylene, Oxford cloth, nylon, nonwoven, ripstop fabrics, Lycra, Mesh, EVA sponge, acrylic fabric, ETFE, PTFE, PE, PU or AC coating material, etc.

Wide Area Laser Cutting Machine CJG-320500LD

Machine Features

• Over-large format flatbed laser cutting machine with the stable patented rainbow structure.

• Designed for tent, awning, marquee, canopy, sunshade, paraglider, parachute, sailing cloth, inflatable castle materials cutting. Suitable for cutting polyester, canvas, tarpaulin, polyamide, polypropylene, Oxford cloth, nylon, nonwoven, ripstop fabrics, Lycra, Mesh, EVA sponge, acrylic fabric, ETFE, PTFE, PE, vinyl, PU or AC coating material, etc.

• Automation. Auto feeding system, vacuum conveyor and collecting working table.

• Over-width working size. 3m, 3.2m, 3.4m, 3.5m optional.

• Over-long material continuous cutting. Capable for cutting 20m, 40m or even longer graphics.

• Saving labor. From design to cutting, only need one person to operate.

• Saving material. User-friendly Marker software, saving 7% or more materials.

• Simplify the process. Multiple use for one machine: cutting fabrics from roll to pieces, marking number on pieces, and drilling (small holes), etc.

Laser Cutting Machine Advantage

• Faltbed Laser cutting with over-large working area

• Smooth, cleaning cutting edge, no reworking necessary

• No fraying of fabric, no deformation of fabric

• Automated production process with conveyor and feeding systems

• Simple production via a PC design grogram

• Complete extraction and filtering of the cutting emissions

Conveyor working table

- › It can process extra length material, and do the continuous processing for material in roll.

- › It makes sure the maximum plainness and the lowest reflectivity.

- › If equipped with the auto-feeder, it can achieve full automatic processing.

Auto feeder

› Automatic feeding system, rectify deviations automatically.

CJG-320500LD Laser Cutting Machine Configuration

| Cutting Area | 3200mm×5000mm (126”×197”) working size customization acceptable |

| Working Table | Vacuum adsorption conveyor working table |

| Laser Type | CO2 DC glass laser tube / CO2 RF metal laser tube |

| Laser Power | CO2 DC glass laser 130 watts, 150 watts / CO2 RF metal laser 150 watts, 300 watts |

| Software | GOLDENLASER cutting software, Vision System, CAD Pattern Designer, Auto Marker |

| Fully Automatic | The gear feeder (optional), the rectify deviation feeding system (optional) |

| Optional | Red light positioning system, Mark pen |

| *** Note: As products are constantly updated, please contact us for latest specifications. *** | |

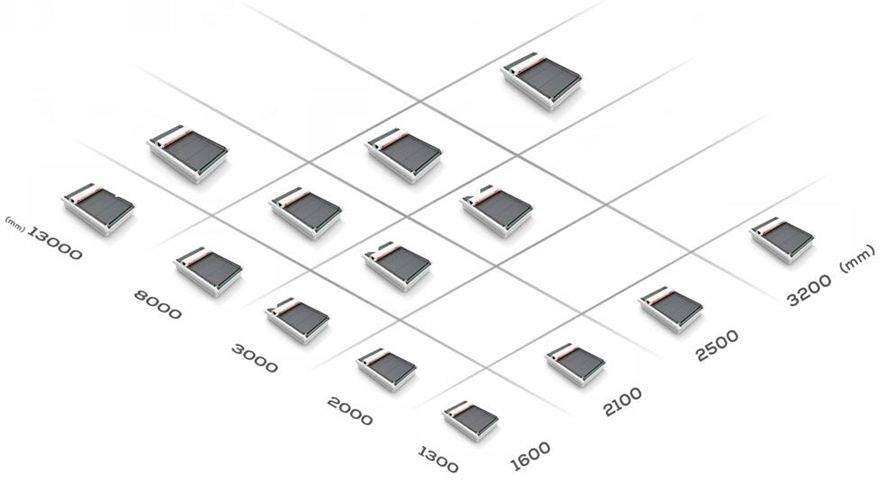

GOLDEN LASER – CO2 Flatbed Laser Cutting Machine

|

Flatbed CO2 Laser Cutting Machine with Conveyor Belts |

Model NO. |

Working Area |

|

CJG-160250LD |

1600mm×2500mm (63” ×98.4”) |

|

|

CJG-160300LD |

1600mm×3000mm (63” ×118.1”) |

|

|

CJG-210300LD |

2100mm×3000mm (82.7” ×118.1”) |

|

|

CJG-250300LD |

2500mm×3000mm (98.4” ×118.1”) |

|

|

CJG-210600LD |

2100mm×6000mm (82.7” ×236.2”) |

|

|

CJG-210800LD |

2100mm×8000mm (82.7” ×315”) |

|

|

CJG-2101100LD |

2100mm×11000mm (82.7” ×433”) |

|

|

CJG-3401100LD |

3400mm×11000mm (133.8” ×433”) |

|

|

CJG-300500LD |

3000mm×5000mm (118.1” ×196.9”) |

|

|

CJG-320500LD |

3200mm×5000mm (126” ×196.9”) |

|

|

CJG-320800LD |

3200mm×8000mm (126” ×315”) |

|

|

CJG-3201000LD |

3200mm×10000mm (126” ×393.7”) |

WORKING AREAS CAN BE CUSTOMIZED

Laser Cutting Machine Application Field

Suitable for cutting polyester, nylon, PVC fabric, Oxford fabric, polyamide fabric, Tarpaulin, canvas, polyamide, polypropylene, nonwoven, ripstop fabrics, Lycra, Mesh, EVA sponge, acrylic fabric, ETFE, PTFE, PE, vinyl, etc.

Laser Cutting industrial Fabrics Sample

Applicable to tent, awning, marquee, canopy, sailcloth, parachute, paraglider, parasail, inflatable castle ,sunshade, umbrella, soft signage, rubber boat, fire balloon, etc.

As the leader of laser solution for flexible fabrics, GODLEN LASER developed large format Flat bed Co2 laser cutting machines for industrial fabric cutting.

Integrated laser cutting, precision unwinding and rewinding, auto marker, continuous cutting of super long material, auto-recognition cutting, marking, scoring and order management together.

Super large working size, fast speed, and high precision, with CE approval.

At present, GOLDEN LASER has developed more than 30 models of laser cutting machines for industrial fabrics and flexible materials. There are 4 series:

(1) Synchronous Belt Series: Synchronous belt transmission with accurate transmission. Stable performance, high efficiency, lubrication-free and easy maintenance. Compared with other laser cutting machines, it has lower cost.

(2) Galvanometer Series: High speed Galvo scanner. Processing speed can reach up to 8000mm/s. Especially suitable for high speed processing of small images.

(3) Galvanometer with X, Y Axis Series: Combining X, Y laser head cutting and Galvo head engraving. No need re-locating. High precision, high efficiency and more convenient.

(4) Double Y-axis Series: with flying route and double Y-axis structure (principal axis and auxiliary axis). The double Y-axis share the weight of gantry and can achieve large format high speed cutting (1200mm/s).

Laser Cutting Machine for Textiles Brief Introduction

Compared with traditional knife or punching processing, laser is advanced CNC technology and a unique non-contact processing, working without any graphical limits and will not produce any mechanical deformation. Laser processing has the advantages of high precision, high speed, no fraying, and high quality results. In addition, applicability of laser processing is more flexible. Laser can do cutting, engraving, hollowing, punching and other processing for a variety of textile, fabrics, garment accessories, leather, fur, shoe, plush toy, home textile, upholstery, carpet, automotive interior, car seat cover, etc. Laser processing technology is more sophisticated, creative and unique.

Golden Laser Technology Advantages:

1. Automatic edge-finding and cutting technology with optic Camera software

2. Multi-head digital movable cutting for plush toys industry

3. Efficient and smart nesting technology

4. Large format high speed engraving and punching technology for home textile fabrics

5. Advantage pattern digitizing technology

6. Long strip flying marking and cutting technology without splicing traces

7. Advanced solutions for genuine leather cutting

8. Super-long material continuous cutting

9. High performance of spreading, feeding and rewinding system

Advantages of Laser Cutting

No burr/fraying with laser cutting

Laser cutting is done by high temperature process. It can make cut edge to close up automatically. Hence, no need to recut the patterns after one-time cutting.

No distortion to the processed fabric

In the process of cutting, laser dose not touch the processed fabric, but laser beam works on the fabric.

High precision

Diameter of the laser beam can be focalized into 0.1mm (we adopt top lens imported from world famous company II-VI-INFRARED).

Cutting is done exactly according to uploaded graphics through computer control.

High efficiency and easy operation

Just upload the graphics into the cutting machine and laser will cut fabric into shapes as designed.