- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

Fabric Laser Cutting Machine with Stripe and Plaid Matching Function

Model No.: CJGV160200LD

Introduction:

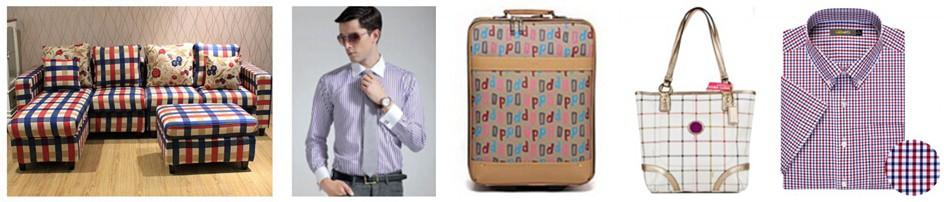

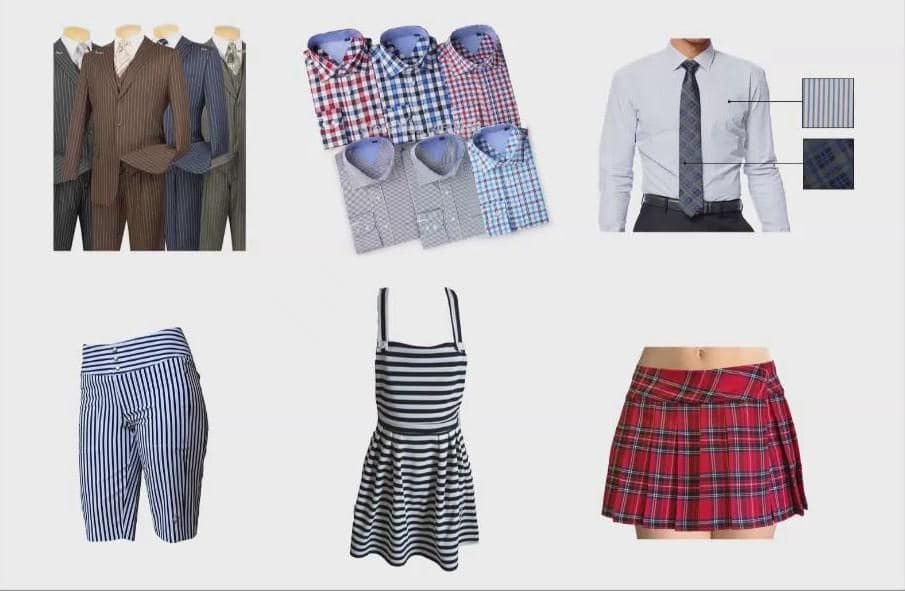

The “stripe and plaid matching” is often encountered in the business of cloth sewing, especially using patterned, striped or plaid fabrics to produce suits, shirts, fashion clothing, footwear and home textile. At the moment when focusing on improving the added value and grade of products, the “stripe and plaid matching” process has become the standard for measuring the quality of such textile products.

Stripe and Plaid Matched Cutting - Option for Goldenlaser’s CO2 Flatbed Laser Cutter

Complete solution for optimization of production processes using stripes, plaids or patterned fabrics.

Stripes or Plaids Matched Laser Cutting Technique

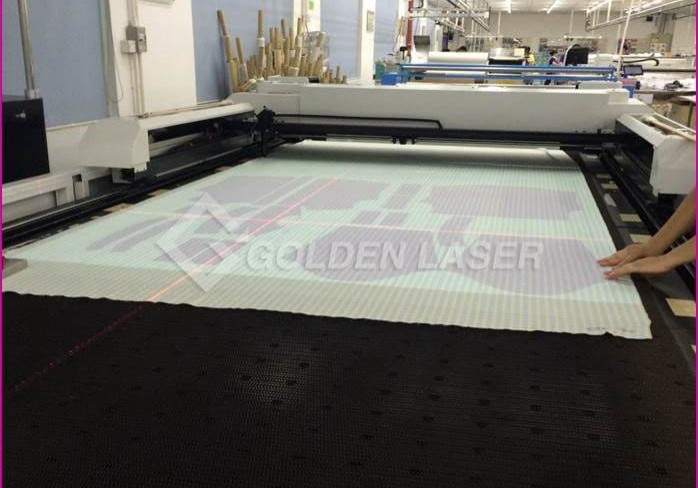

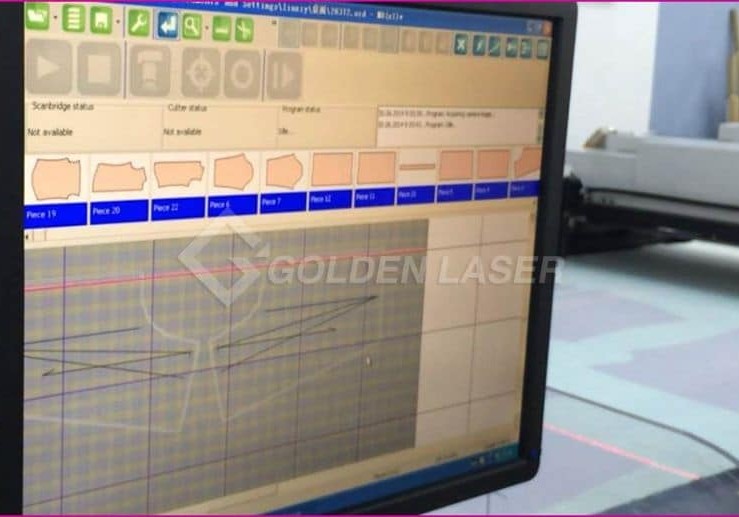

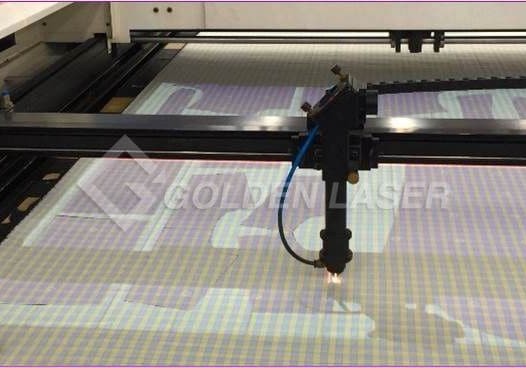

CCD camera, which is installed in the rear of the laser cutting bed, can recognize materials information such as stripes or plaids according to color contrast. The nesting system can perform automatic nesting depending on the graphical information and pieces identified requirement as well as adjusting the pieces angle to avoid stripes or plaids distortion caused by the feeding. After nesting, the projector would emit red light to mark the cutting lines on materials for calibration.

Machine Features

WORKFLOW

The Laser Cutting System delivers a complete solution for automatic alignment of markers to fabric stripes and plaids.

Step 1

Conveying Fabric from Roll

Step 2

Projection Positioning

Step 3

Capture, Marker Matching

Step 4

Import Cutting File

Step 5

Start Laser Cutting

Technical Specifications

| Laser type | CO2 DC glass laser / RF metal laser |

| Laser power | 150W |

| Working area | 1600mm×2000mm |

| Working table | Conveyor working table |

| Processing speed | 0-600 mm/s |

| Positioning accuracy | ±0.1mm |

| Motion system | Servo motor |

| Cooling system | Constant temperature water chiller |

| Power supply | AC220V±5% 50/60Hz |

| Graphics format supported | AI, BMP, PLT, DXF, DST |

| Standard collocation | 2 sets of German cameras, 1 set of 550W top exhaust fan, 2 sets of 1100W bottom exhaust fans, mini air compressor |

Laser Cutting Samples & Applications