Laser Cutting Solutions for Filter Media

Filtration Industry Introduction

As an important environmental protection and safety control process, filtration has been widely used in many fields, from industrial gas-solid separation, gas-liquid separation, solid-liquid separation, solid-solid separation, to air purification and water purification of daily home appliances. Specific applications include waste gas emission treatment in power plants, steel plants, cement plants, air filtration in textile and garment industry, sewage treatment, filtration and crystallization in chemical industry, air filtration in automobile industry, oil circuit filtration, and air filtration in household air conditioners and vacuum cleaners.

Currently, the filter materials are mainly fiber materials, woven fabrics. In particular, fiber materials are mainly synthetic fibers such as cotton, wool, linen, silk, viscose fiber, polypropylene, nylon, polyester, polyurethane, aramid, as well as glass fiber, ceramic fiber, metal fiber, etc.

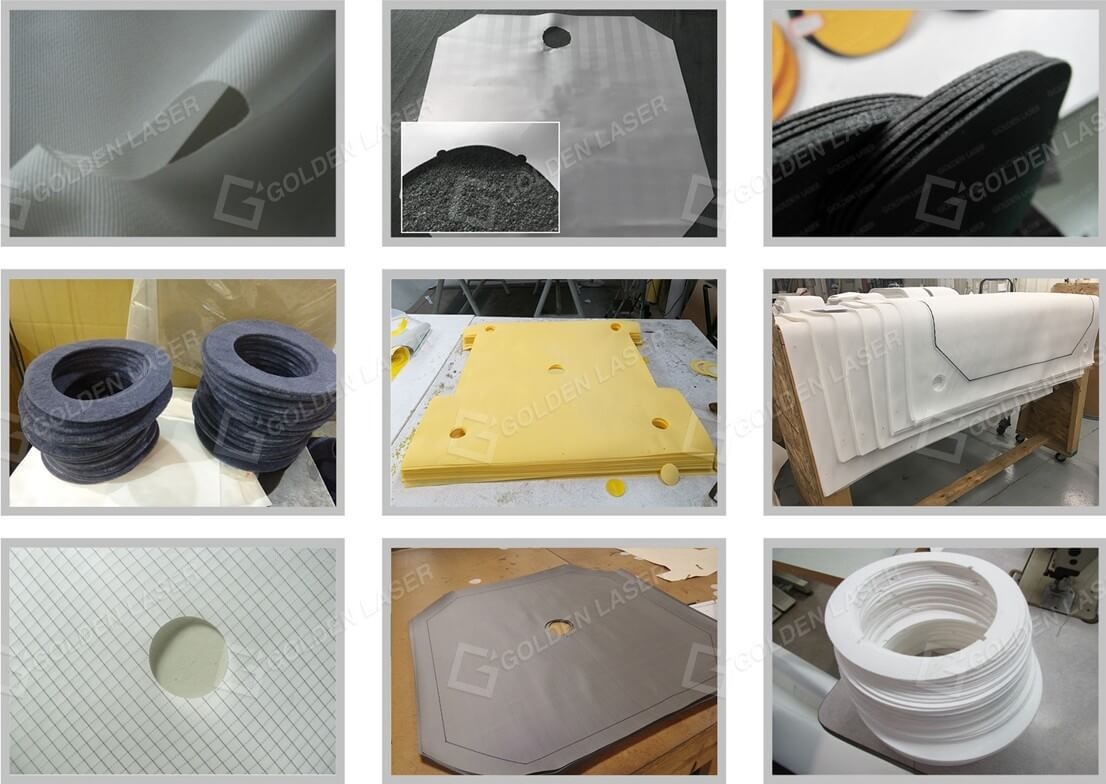

With the continuous expansion of the application fields of filtration, new filter materials are constantly emerging, and the filtration products range from filter press cloth, dust cloth, dust bag, filter screen, filter cartridge, filter barrels, filters, filter cotton to filter element.

Goldenlaser offers CO₂ laser cutters for technical textiles

Large format CO2 laser cutting machine is ideal for cutting filtration medium thanks to the non-contact process and high precision achieved by the laser beam. In addition, the thermal laser process ensures the cutting edges are automatically sealed when cutting technical textiles. Since the laser cut filter cloth does not fray, subsequent processing becomes easier.

What benefits do goldenlaser CO2 laser cutting machines have for cutting filter media?

Laser cutting has become a trend for filter industry

Exact fabric shapes can be made through CAD programming and exchanged to our CO2 laser cutters. You are guaranteed exactness, speed and a definitive in quality of filter media processing.

Applications in filter industry

• Dust collection bags / Filtration press cloth / Industrial filtration belts / Filter cartridge / Filter paper / Mesh fabric

• Air Filtration / Fluidization / Liquid filtration / Technical fabrics

• Drying / Dust Filtration / Screening / Solid filtration

• Water filtration / Food filtration / Industrial filtration

• Mining filtration / Oil and gas filtration / Pulp and paper filtration

• Textile air dispersion products

Filter materials suitable for laser cutting

Filter fabric, glass fiber, non-woven fabric, paper, foam, cotton, polypropylene, polyester, polyamides, nylon, PTFE, sox duct and other industrial fabrics.

We recommend the CO2 laser machines for cutting filter cloth

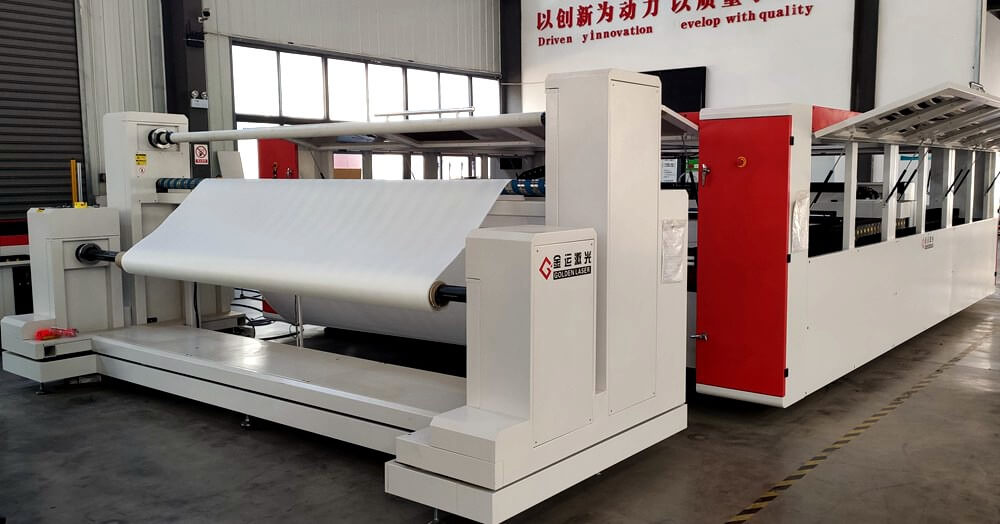

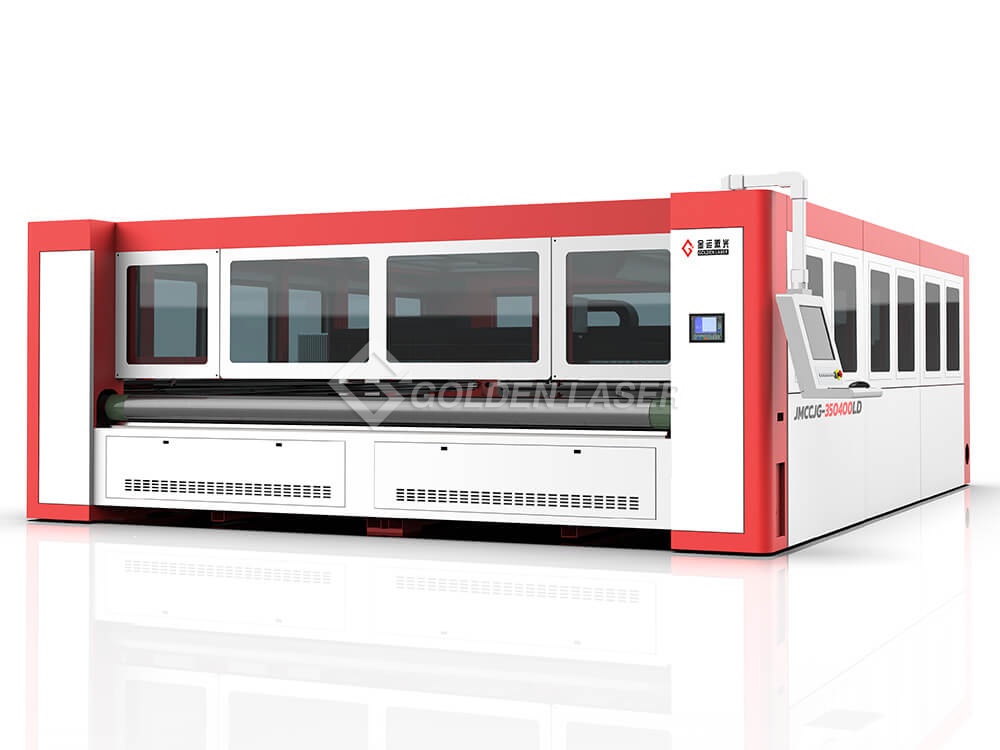

GOLDENLASER JMC Series High Speed High Precision CO2 Flat Bed Laser Cutter in Details

Four Reasons

to Choose GOLDENLASER JMC SERIES CO2 Laser Cutting Machine

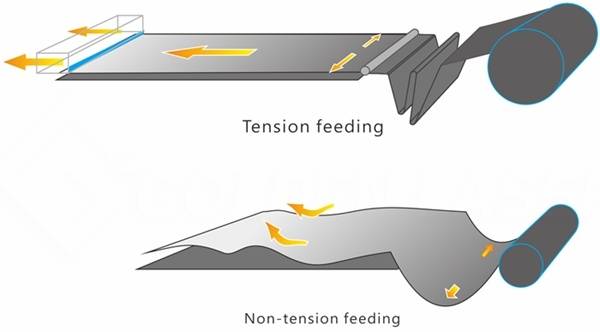

1. Precision tension feeding

No tension feeder will easy to distort the variant in the feeding process, resulting the ordinary correction function multiplier; Tension feeder in a comprehensive fixed on both sides of the material at the same time, with automatically pull the cloth delivery by roller, all process with tension, it will be perfect correction and feeding precision.

2. High-speed cutting

Rack and pinion motion system equipped with high-power laser tube, reaches to 1200 mm/s cutting speed, 8000 mm/s2 acceleration speed.

3. Automatic sorting system

Fully automatic sorting system. Material feeding, cutting, sorting at one time.

4. Working areas can be customized

2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), Or optional. The largest working area is up to 3200mm×12000mm (126in×472.4in)