Laser Kiss-Cutting

Laser Kiss Cutting is a specialized and precise cutting technique that utilizes a laser to create shallow cuts or score lines on a thin, flexible material while leaving the backing or substrate intact. This process is often used in various industries, including label manufacturing, packaging, and graphics production, where the goal is to produce adhesive-backed products, stickers, decals, or intricate shapes with clean, sharp edges.

Laser kiss cutting offers several advantages, including high precision, speed, and the ability to cut intricate shapes with fine detail. It is commonly used in applications where maintaining the backing or substrate's integrity is essential, as it ensures easy handling and application of the final product.

Laser Kiss Cutting is a laser-based cutting technique that delicately scores or cuts thin, flexible materials, allowing the top layer to be cleanly separated from its backing while preserving the integrity of the underlying substrate. This method is widely employed for the efficient production of adhesive-backed items like labels, decals, and custom-shaped graphics.

Advantage of Laser Kiss-Cutting

Some of the many advantages of laser kiss-cutting with Golden Laser’s equipment

Laser kiss-cutting for digital converting

Laser kiss cutting stickers roll to roll

Laser converting is used to perform converting processes that would be difficult or impossible to achieve with conventional mechanical methods.

Laser kiss cutting, a typical digital converting application, is particularly used in the production of adhesive labels.

Laser kiss cutting allows to cut the top layer of a material without cutting through an attached material. By using the right settings, the label can be cut without cutting the backing material like an adhesive foil.

This technique makes production particularly efficient and advantageous, since the costs and time required to set up the machine are eliminated.

In this sector, the materials most used for kiss cutting are:

• Paper and derivatives

• PET

• PP

• BOPP

• Plastic film

• Double sided tape

Laser kiss cutting for textile decoration sectors

In the textile segment, semi-finished fabrics and finished garments can be embellished via laser kiss cutting and laser cutting. For the latter, laser kiss cutting is exceptionally beneficial for the production of personalized decorations.

This method enables the creation of a variety of effects, including appliqués, embroideries, patches, heat transfer vinyl, and athletic tackle twill.

In this category of applications, two fabric sections are typically joined together. In the subsequent step, cut out a shape from the fabric's surface layer using laser kiss-cutting. The topmost figure is then eliminated, revealing the underlying illustration.

Laser kiss cutting is primarily applied on the following textile types:

• Synthetic fabrics in general, in particular polyester and polyethylene

• Natural fabrics, especially cotton

When it come to adhesive backed athletic tackle twill, the "Laser Kiss Cut" process is especially suitable for multi-color, multi-layer athletic tackle twill for Jersey player nameplates and back and shoulder numbers.

Laser equipment suitable for laser kiss-cutting

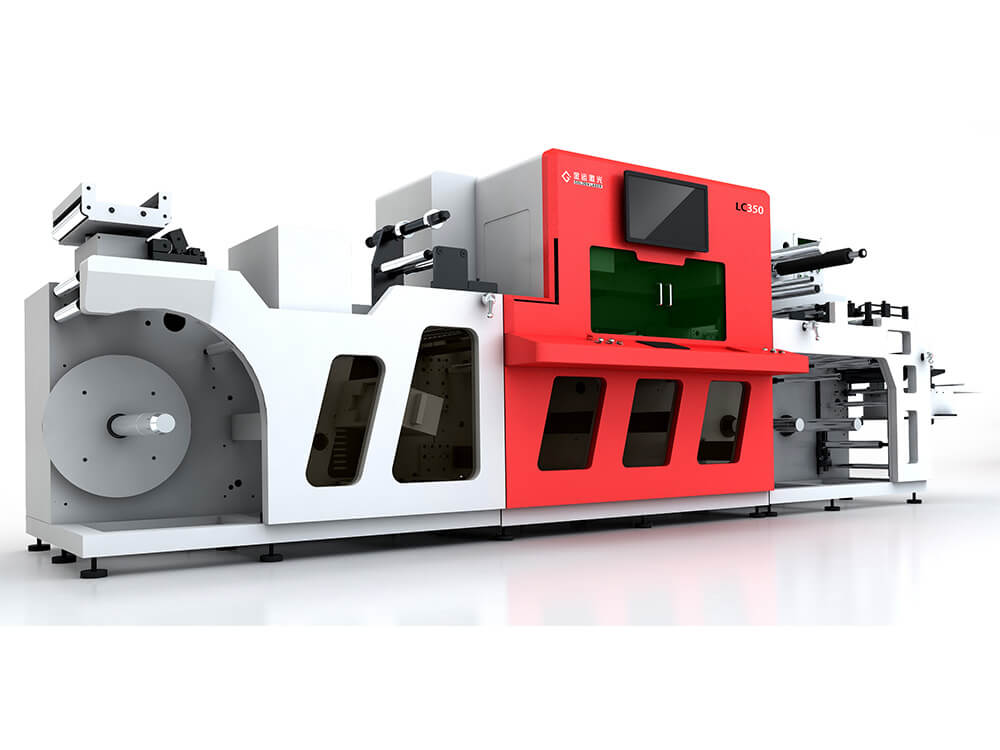

LC350

Roll to Roll Laser Cutting Machine

LC350 is fully digital, high speed and automatic with roll-to-roll application. It delivers high quality, on-demand converting of roll materials, dramatically reducing lead time and eliminating the costs through a complete, efficient digital workflow.

LC230

LC230 is a compact, economic and fully digital laser finishing machine. The standard configuration has unwinding, laser cutting, rewinding and waste matrix removal units. It is prepared for add-on modules such as UV varnish, lamination and slitting, etc.

LC8060

Sheet Fed Laser Cutting Machine

LC8060 features continuous sheet loading, laser cutting on-the-fly and automatic collection working mode. The steel conveyor moves the sheet continuously to the appropriate position under the laser beam.

LC5035

Expand production versatility by integrating a Golden Laser LC5035 into your sheet-fed operations and gain the ability to full cut, kiss cut, perforate, etch and score in a single station. The ideal solution for paper products like labels, greeting cards, invitations, folding cartons.

ZJJG-16080LD

Flying Galvo Laser Cutting Machine

ZJJG-16080LD adopts full flying optical path, equipped with CO2 glass laser tube and camera recognition system. It is an economical version of gear & rack driven type JMCZJJG(3D)170200LD.

JMCZJJG(3D)170200LD

Galvo & Gantry Laser Engraving Cutting Machine

This CO2 laser system combines galvanometer and X-Y gantry, sharing one laser tube. The galvanometer offers high speed engraving, marking, perforating and cutting of thin materials, while X-Y Gantry allows processing of larger profile and thicker stock.