Laser cutting of spacer mesh fabrics and car heated seats

Car seats are essential for passengers among all other automotive interior upholstery. Glassfiber composite materials, thermal insulation mats and knitted spacer fabrics in the manufacture of car seats are now increasingly being processed by lasers. No need to store dies tool in your manufactory and workshop. You can realize textiles processing for all kinds of car seats with laser systems.

Not just the stuffing inside the chair, the seat cover also plays a role. Seat cover, made of leather of synthetic leather, is suitable for laser processing as well. CO2 laser cutting system is suitable for cutting technical textiles, leather and upholstery fabrics in high precision. And Galvo laser system is ideal to perforate holes on seat covers. It can perforate any size, any amount and any layout of holes on the seat covers easily.

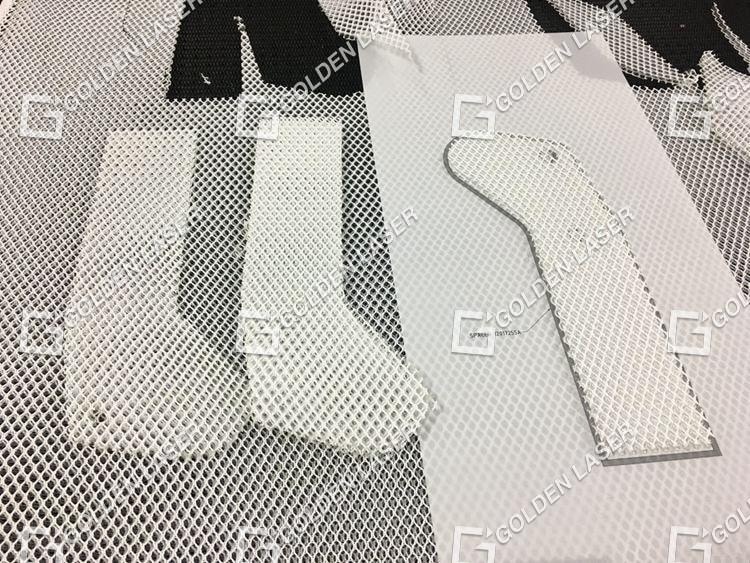

Thermal technology for the car seats is a quite common application now. Each technology innovation not only upgrades the products but also pays close attention to the users. The optimal goal of thermal technology is to create the highest level of comfort for passengers and elevate the driving experiences. The traditional process to manufacture automotive heated seat is to die cut the cushions first and then stitch the conductive wire on the cushion. Such a method results in poor cutting effect leaves material scraps everywhere and is time-consuming. While laser cutting machine, on the other hand, simplifies the whole manufacturing steps, improves the production efficiency, and saves production materials and time for manufacturers. It highly benefits the customers with high-quality Climate Control Seats.

Related Seat Applications

Infant car seat, booster seat, seat heater, car seat warmers, seat cushion, seat cover, car filter, climate control seat, seat comfort, armrest, thermoelectrically heat car seat