Cutting and Perforating Holes of Textile Ventilation Ducts with Laser

The air dispersion fabric is definitely a better solution for ventilation while it is a big challenge to make the constant holes along the 30 yards long or even longer fabrics and you have to cut the pieces out besides for making the holes. Only laser can realize this process.

Goldenlaser specifically designed CO2 laser machines that fulfill the exact cutting and perforating of textile ventilation ducts made of specialty fabrics.

Benefits of Laser Processing Textile Ventilation Ducts

Smooth and clean cutting edges

Cutting the dispersion holes constantly matching the drawing

Conveyor system for automatic processing

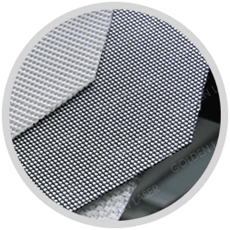

Applicable Materials

Types of Common Fabric Duct Materials for Air Dispersion Suitable for Laser Cutting and Perforating

Polyether Sulfone (PES), Polyethylene, Polyester, Nylon, Glass Fiber, etc.

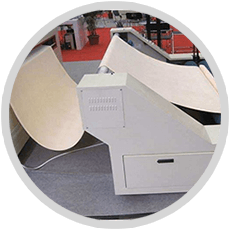

Laser Machines Recommendation

• Features a gantry laser (for cutting) + a high speed galvanometric laser (for perforation and marking)

• Automatic processing directly from roll with the help of feeding, conveyor and winding systems

• Perforation, micro perforation and cutting with extreme precision

• High-speed cutting for plenty of perforation holes within a short time

• Continuous and full-automatic cutting cycles of infinite lengths

• Specifically designed to laser process of specialty fabrics and technical textiles

Model No.: ZJ(3D)-16080LDII

• Equipped with two galvanometer heads that work simultaneously.

• Laser systems use the flying optics structure, providing a large processing area and high precision.

• Equipped with a feeding system (correction feeder) for continuous automated processing of rolls.

• Uses world-class RF CO2 laser sources for superior processing performance.

• Specially developed laser motion control system and flying optical path structure ensure precise and smooth laser movement.