Would you like to get more options and availability of Goldenlaser Machines and Solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

Laser Cutting Machine for 3M VHB Tape

3M™ VHB™ tapes are a line of double-sided foam tapes constructed from high-performance acrylic adhesives that are available in a variety of sizes. Compared to traditional double-sided foam tapes, 3M™ VHB™ tapes are capable of forming bindings of remarkable strength and have superior endurance and flexibility. In industrial production, 3M™ VHB™ adhesive tapes need to be matched to the demanding requirements, produced with the exact shape, fit and function required.

Laser cutting is a technology that utilizes a high-energy laser beam to precision cut shapes or designs out of materials. Many 3M materials are well suited to be laser cut to specific specifications and manufacturing needs.

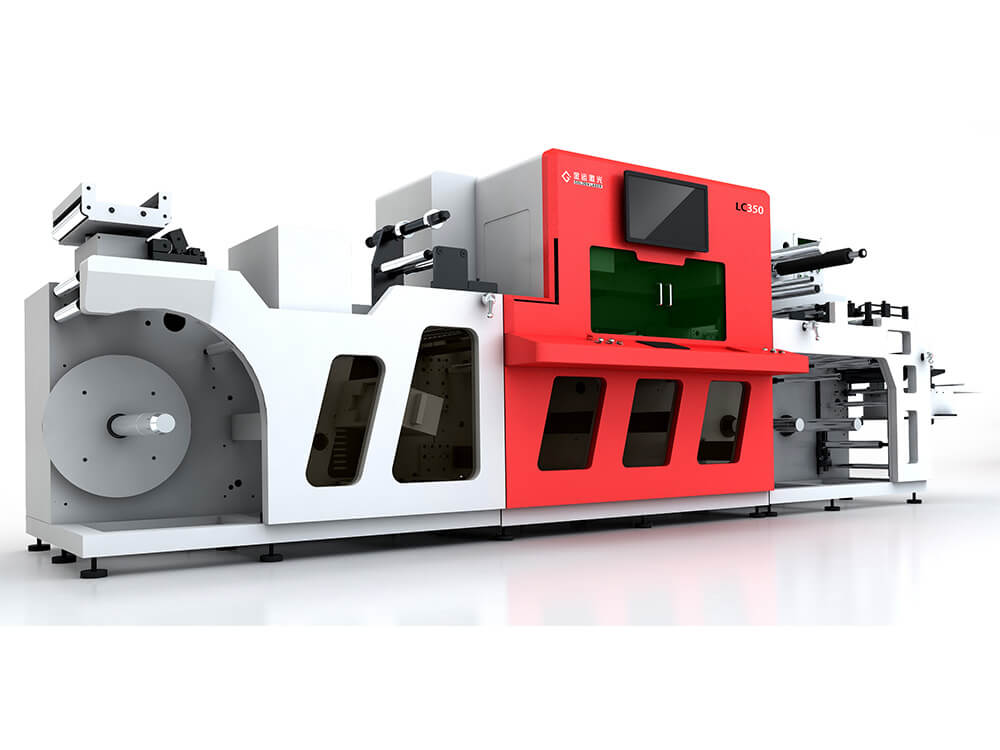

Goldenlaser developed digital laser die cutters designed to cater for the precise performance specifications and continuous cutting jobs that are of concern to converters today.

Recommended Laser Machines

Goldenlaser offers digital roll-to-roll laser cutting machines for 3M VHB Double Sided Tape

| Model No. |

LC350 |

LC230 |

| Max. cutting width |

350mm |

230mm |

| Max. cutting length |

Unlimited |

|

| Max. width of feeding |

370mm |

240mm |

| Max. web diameter |

750mm |

400mm |

| Max. web speed |

120m/min |

60m/min |

|

(depending on laser power, material and cut pattern) |

||

| Accuracy |

±0.1mm |

|

| Laser source |

CO2 RF laser |

|

| Laser power |

150W / 300W / 600W |

100W / 150W / 300W |

| Laser power output range |

5%-100% |

|

| Power supply |

380V 50/60Hz Three phase |

|

| Diameter |

L3700 x W2000 x H1820mm |

L2400 x W1800 x H1800mm |

| Weight |

3500KG |

1500KG |

Watch Roll to Roll Laser Cutting 3M VHB Tapes in Action

Benefit of Laser Cutting 3M™ VHB™ Tape

Laser die-cutting offers a number of benefits to 3M tape converters, including: speeding up the assembly process, optimizing the manufacturing process and improving the quality of custom adhesive tapes.

- No Tooling Cost

With conventional die cutting, unique shapes can be expensive in tooling cost. With laser cutting no tooling cost is required, because there is no tool, except the laser itself! Laser die cutting helps to eliminate the storage, lead times, and costs of traditional dies.

- High Precision

With conventional die cutting, meeting certain tolerance expectations on highly complex parts can be a challenge. Laser die cutting provides for better accuracy and tighter tolerances, allowing for more complex geometries to be created.

- Increased Flexibility in Designs

One of the downsides of using conventional die cutting is that once the tool is made it can be difficult to adjust. Another benefit of laser die cutting is that design changes can be made very quickly, and there are unlimited cutting paths available.

- Contactless Machining, No Tool Wear

When cutting VHB™ tape with a conventional die cutter or knife cutter, the blade can easily become dull due to the adhesive of the VHB™ tape sticking to the blade. However, laser cutting is a non-contact process with no tool wear.

- Increased Edge Quality

3M VHB tapes are easily laser converted into any perform shape or profile. With or without carrier films and protective liners, single sided or double-sided adhesives can be cleanly laser cut, creating clean, consistent cutting edges.

- Full Cut, Kiss Cut & Engrave on Same Layout

With laser die cutting, there are a variety of unique capabilities and functions options available, including full cutting (cut through), kiss cut, engraving on same layout.

Applications of Laser Cutting

Laser die cutting is used to optimize processes, applications, and production across a wide range of industries including electronic, automotive, printing, packaging, medical, metalworking, woodworking, HVAC and other specialty industries.

Laser cutting 3M tape roll to sheet

When you need just-in-time manufacturing, laser technology is the ideal converting solution. Machines with this capability increase the accuracy of your overall production by ensuring clean lines and precise detailing on your finished products. You may want to consider laser cutting if you are currently converting components from the following materials: