Do you have questions or are there technical matters you would like to discuss? If so, you are very welcome to contact us! Please just complete the form below. Our specialists are always happy to help and will get back to you promptly.

Laser Cutting of Synthetic Textiles

Laser processing available on synthetic textiles:

1. Laser cutting

The energy of the CO2 laser beam is readily absorbed by the synthetic fabric. When the laser power is high enough, it will cut through the fabric completely. When cutting with a laser, most synthetic fabrics vaporize quickly, resulting in clean, smooth edges with minimal heat-affected zones.

2. Laser engraving (laser marking)

The power of the CO2 laser beam can be controlled in order to remove (engrave) the material to a certain depth. The laser engraving process can be used to create intricate patterns and designs on the surface of synthetic textiles.

3. Laser perforation

CO2 laser is capable of perforating tiny and accurate holes on synthetic fabrics. Compared to mechanical perforation, laser offers speed, flexibility, resolution and accuracy. Laser perforation of textiles is neat and clean, with good consistency and no subsequent processing.

The benefits of cutting synthetic textiles using lasers:

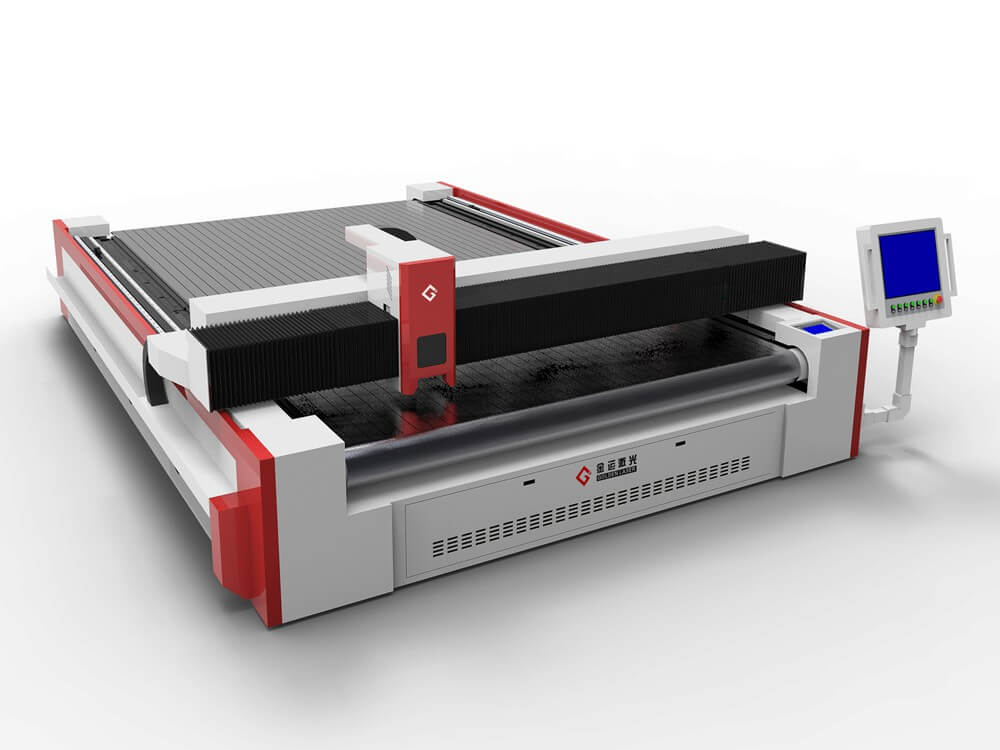

The Advantages of goldenlaser's laser cutting machines for fabric:

Material information for the laser cutting of synthetic textiles:

Synthetic fibers are made from synthesized polymers based on raw materials such as petroleum. The different types of fibers are produced from widely diverse chemical compounds. Each synthetic fiber has unique properties and characteristics that suit it for specific applications. Four synthetic fibers - polyester, polyamide (nylon), acrylic and polyolefin - dominate the textile market. Synthetic fabrics are used in a broad variety of industries and sectors, including, apparel, furnishing, filtration, automotive, aerospace, marine, etc.

Synthetic fabrics are usually composed of plastics, such as polyester, that respond very well to laser processing. The laser beam melts these fabrics in a controlled manner, resulting in burr-free and sealed edges.