Enhancing your business with laser cutter

Intelligent Production or Industrial 4.0 doesn’t need to be complicated or unreachable as it sounds. Golden Laser specifically serves large, medium-sized and small factories and helps upgrade production mode by implanting laser technology into manufacturing procedures. In this article, we give you an insight into the benefits a laser cutting machine can bring to your business.

1. When size matters

With the forming of the global market, more much competing and more demands of personalized products, the way of Make-To-Stocks (MTS) is changed to Make-To-Order (MTO). As a result of MTO, orders come in all sizes – small and large – and they all require proper finishing. Not to discuss the defects of manual processing, we shall focus on the point where a flatbed laser cutter can come in “handy”, to not only shorten you precious time but save your money as well.

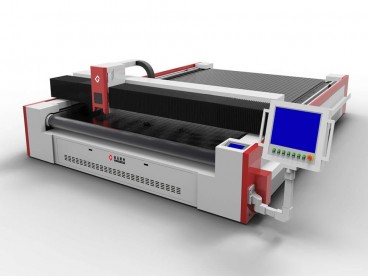

With Golden Laser, you can obtain excellent accuracy using automated laser systems. A flatbed laser cutter would be your best workmate, especially when you want to cut a wide variety of materials and applications. Golden Laser’s range of flatbed cutter sizes can serve each and everyone and we will help you decide which laser system suits best for you.

2. Cut a large variety of jobs with the same flatbed cutter

If you aspire to grow your business, you have to be ready to take on any job. Whether this means cutting 1.000 embroidery patches of the same size or few material samples for an upcoming promotion, you need a system that is cut out for any job, each time again.

The list below is merely a fragment of what a Golden Laser flatbed cutting machine can finish for you:

· Apparel and sportswear

· Automotive Interior Upholstery

· Abrasive Papers

· Patches and flags

· Filter Cloth

· Fabric Air Dispersion

· Insulation Materials

· Textiles (Mesh fabrics, flags, banners,…)

3. Optimize your workflow with these media handling features

Did you know that your future technical textile laser cutter from Golden Laser has many features to improve your workflow? The turnover time to make each order will be greatly shortened with these features!

Get your production up and running with the following options:

· The Auto Feeder can hold the roll flexible materials and continually deliver materials into the machine.

· The Enclosed Doors make the processing safer and reduce stimulating air and dust that may be generated during processing.

· The Marking Systems can draws graphics and labels on your material.

· The Honeycomb Conveyor makes continuous processing of your products.

· The Red Light position can check whether your roll material on both sides is aligned.

· The Automatic Oiler can oil the track and rack to avoid them rusting.

4. Automated Software to make your workflow even more efficient

If you want to boost efficiency, Golden Laser’s Auto Maker Software will help to deliver fast with uncompromised quality. Our nesting software with the help of which your cutting files will perfectly be placed on the material. You will optimize the exploitation of your area and minimize your material consumption with the powerful nesting module.

Golden Laser, a laser cutting machine manufacturer, offers a robust, versatile and flexible laser finishing solution, which will help companies to increase their productivity, to provide their customers with a high quality finished product.