Golden laser at ITMA in Barcelona

ITMA – the International Exhibition of Textile Machinery, which has been held every four years, came to an end on September 29th after lasting for 8 days. As the leading enterprise for laser application in textile and garment industry and the pioneer of laser application industry, GOLDEN LASER took part in the exhibition and drew great attention from the industry.

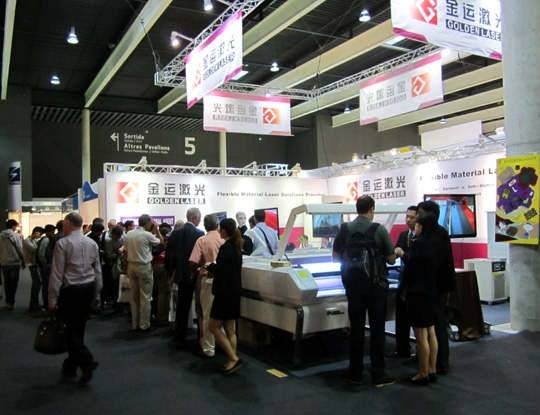

ITMA, as the world’s largest top professional international exhibition concerning textile and garment machinery field, is recognized as the platform that connected global textile machinery design, processing manufacturing and technical application. ITMA 2011 gathered 1000 enterprises from 40 countries which have shown their products vigorously. At his exhibition, exhibition area of GOLDEN LASER reached 80 m2.

After our great success in Munich Germany in 2007, GOLDEN LASER introduced new products–the four series of MARS, SATURN, NEPTUNE and URANUS laser machines at this exhibition. During the exhibition, we attracted 1000 clients to register their information and the clients made an intense echo.

The NEPTUNE series which innovatively integrate the computer embroidery machine and laser cutting and engraving machine, has greatly enriched traditional embroidery process. The introduction of this series aroused wide attention of the clients from India and turkey. As what the India client said ‘the come out of this series will make an extraordinary sense on the process innovation of Indian traditional garment industry’.

The SATURN series is specially developed for continuous engraving on large format materials. Its application will not only highly raise the additional value of home textile products, but also it may replace the traditional washing process in the field of jean pattering that is becoming more and more popular in Europe and America.

Soccer, basketball and other sports are very popular in Europe and America districts, which has brought about the booming of sportswear ‘jersey’ production. Spraying digital printing or screen printing process is usually applied in the colorful pictures of jerseys. After spraying digital printing or screen printing is finished, edge-following cutting is used on the pictures. However, hand cutting nor electrical cutting can not make precise cutting, which may lead to low qualifying rate of the products. The URANUS series high-speed cutting machine increases the speed by one time comparing with the common cutting machine and has auto-recognition cutting function as well. It can do continuous automatic edge-following cutting on jerseys and other types of garments. It can cut with high precision and higher efficiency. So, when it was presented on the GOLDEN LASER exhibition showcase, it logically attracted a lot of garment producers from Europe and America, and some of them even signed the orders.

The MARS series is considered as the combination of art and technique. It first uses automobile technology in laser equipment production. So, it drew many distributors to purchase the machine. This series applies flow-line industrial production model and uses mould production. It first realizes apparatus standardization and modularization and greatly reduces the failure rate of the equipment. In appearance,it has streamline design and baking varnish process which is always used in automobile industry. One of our clients said “MARS laser machine is not only an excellent product but also a piece of artwork worth of processing.”

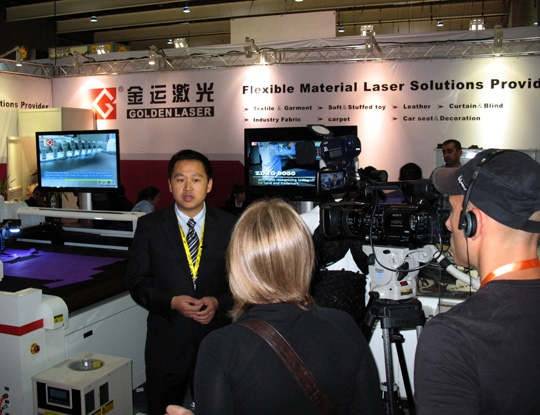

At this exhibition, GOLDEN LASER displayed both the machines and the videos at the exhibition. To our surprise, many of our clients directly signed the purchase contract after they watched the videos even without seeing the real machine. We believe that shows that our customers have deep trust in the products from GOLDEN LASER and it also proves that GOLDEN LASER has a great influence on the foreign market. Undoubtedly, that means the customers have shown great recognition on GOLDEN LASER and other laser enterprises in China.