Vision Camera Laser for Dye-sublimation Printed Fabrics and Textiles Cutting

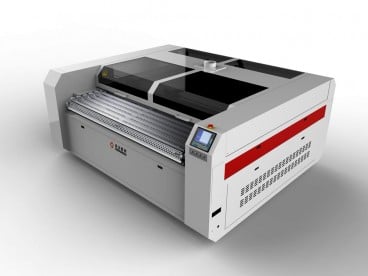

Traditional manually cutting or mechanical cutting has many limitations on processing digital printing sublimation fabrics such as sportswear, fashion garment, team jerseys, etc. Nowadays vision laser cutting machine from Goldenlaser becomes an ideal choice for the printed materials of all shapes and sizes precise cutting.

Goldenlaser CAD vision scanning laser system solves the problem of position deviation, rotation angle, and elastic stretching during the cutting process.

How Scanning Laser Cutter work automatically?

1. Loading the dye-sublimated roll fabrics to the conveyor working table of laser cutter with auto-feeder.

2. HD Cameras scan the fabrics, detect and recognize the printed contour, and send the information to the laser cutter.

3. Set the cutting parameters. Press “start” button on the laser cutter. Then the laser cutting machine will do cutting automatically.

4. Laser cutting and repeat the whole process.

What advantages can Goldenlaser Vision Laser Cutting Machine bring to you?

- Save tool cost and labor cost

- Simplify your production, automatic cutting for roll fabrics

- High output (500 sets of jersey per day per shift – only for reference)

- No required the original graphics files

- High precision

In addition to the above applications, Goldenlaser Vision Laser Cutting Machine can also be applied in jersey, swimwear, cycling apparel, team uniforms, sports shoes, banners, flags, bags, suitcases, soft toys, etc. Goldenlaser’s laser cutting system gives you the capability to create custom prototypes and mass produce for your application, no matter how small or large it is. You will receive the highest-precision cutting, accuracy, and product consistency that you deserve.