SGIA Expo 2015, Golden Laser again cooperation with sports brand giant

2015 SGIA Expo (Atlanta, November 4~6) , is the screen printing and digital printing industry event, is by far the largest and most authoritative screen printing, digital printing and Imaging technology exhibition in the United States, is also one of the world’s three most popular printing exhibition.

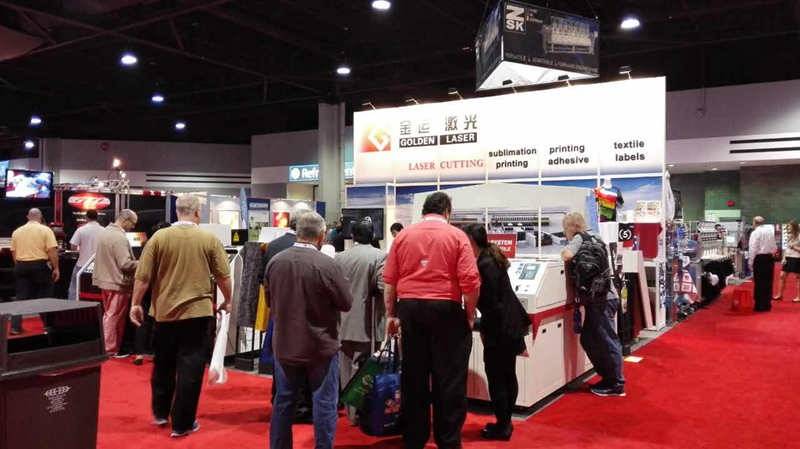

On the morning of the first day SGIA Expo 2015 Overview

On the morning of the first day SGIA Expo 2015 Overview

On the first day of SGIA Expo 2015, passionate visitors in an endless stream came to visit our booth to look for the best laser solution!

In recent years, we have been exploring to take advantage of the laser for the deep processing of printing fabrics, especially the stretch printed fabric. This time, we took the lead in the Expo to present printed fabric recognizing, cutting & perforating integrated laser solution that provide highly efficient automated processing methods for the apparel manufacturers. This solution has been recognized by visitors. And on the spot, sportswear giants Nike reached agreement with us and make an order for jersey high-speed laser perforating system.

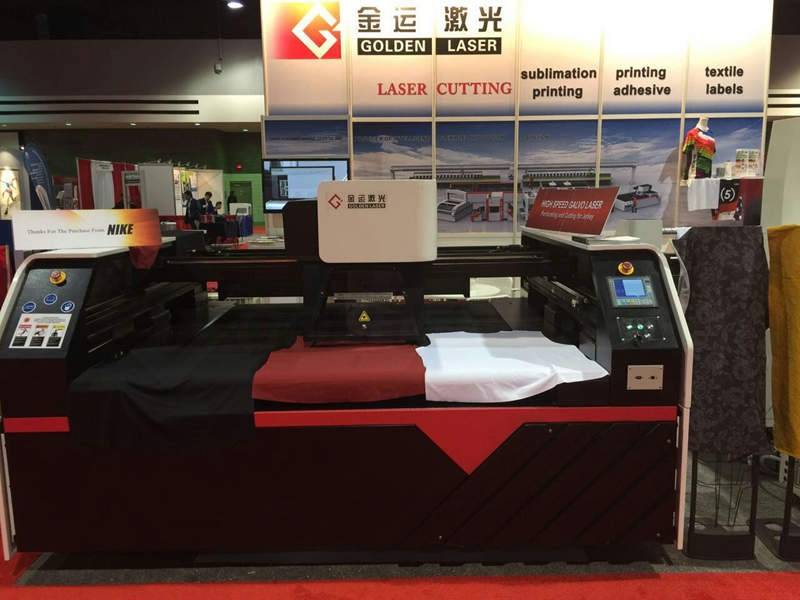

Jersey high-speed laser perforating system

Jersey high-speed laser perforating system

Jersey high-speed laser perforating system is specifically developed for sportswear breathable fabrics. To test the fabrics, perforating time is only 25 seconds for an approximately 70cm * 90cm sportswear fabric piece, and the effect is even, clean and fine, which makes them very satisfied.

We also tested other fabrics, laser perforating about 34 cm * 14 cm jersey fabric, the time required is only 4 seconds, perforating effect is also very delicate.

According to the characteristics of sportswear small batch customization demand, we developed VisionLASER intelligent recognition laser cutting system, to realize the automatic identification printing sportswear fabric cutting.

Vision Laser Cutting System for Sportswear

Vision Laser Cutting System for Sportswear

When we talked to on-site visitors, we have a smart Vision laser system that can cut 200~500 sets of different sizes of sportswear per day, they all exclaimed “Amazing”!

As we know, the traditional custom sportswear is made by manual or electric scissors. It is inefficient, error, tedious process, not suitable for small quantities or custom clothing. However, using this laser system, just need to put the printed fabric roll in to the feeder, and then you can get accurate cutting fabric. Do not need manual intervention completely. Do not need printing sample pattern. The laser machine will scan the pattern, identify the cutting contour, and finally alignment cutting. Fast cutting efficiency and good quality.

Every year, SEMA Expo shows the world’s most advanced printing technology and the most popular printing applications, let us feel the Americas is the uncompromising sports hot land. In October this year, we have also set up the Americas overseas marketing service center. We will continue to provide users with better products, and more comprehensive support and services.