OEM/ODM Factory for Smart Vision CO2 Laser Cutter for Fabric with Camera to Sri Lanka Manufacturer

Detail:

Versatile Vision CO2 Laser Cutter with Camera

ZDMJG-160100LD

• One shot format up to 1600mm, direct extraction of contour cutting, process supporting partial or total modification.

• This laser cutter can realize continuous feeding, auto-recognition and cutting, process can be adjusted, without affecting the cutting accuracy, avoid errors due to feeding.

• Software enables man-machine interaction, real-time validation cutting path.

• This laser cutter can achieve inside and outside contour cutting.

• When cutting multiple graphics, you can specify the size of the graphic cut.

• It has the 5th generation CCD multi-template cutting function.

• The projector can be mounted on the inner projection format graphics exact positioning without alignment template

• The projector can be mounted alternatively to precise positioning projection of the graphics within the format, no required alignment template.

| Two recognition mode | |

| Edge-seeking recognition mode | Multi-template recognition mode |

| √√√ No limitation of graphic size or templates. One time shooting of camera, any complex graphics can be precisely cut. | |

|

|

|

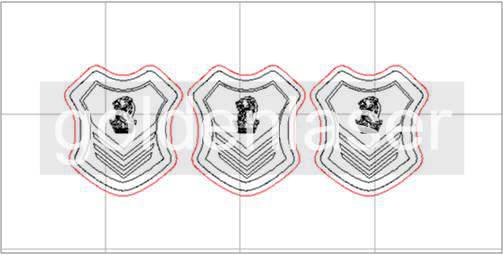

Machining process (As shown above) 1、Camera shooting graphics 2、Vision software to extract contour of graphics (the red mark part as above) 3、Laser cutting along the red outline |

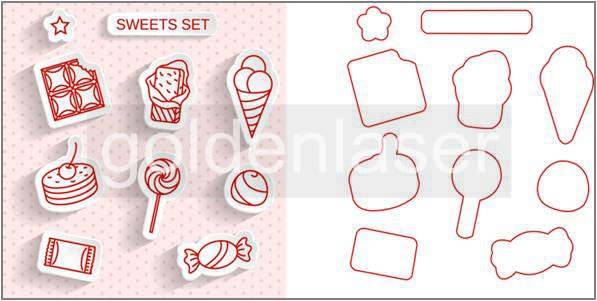

Machining process (As shown above) 1、The camera captures the whole pattern 2、Import graphics templates in the Template Management (the vector drawing part as above) 3、Laser cutting with template |

| Advantages: Always recognition of the contour of graphics even if material is deformed stretching. | Advantages: suitable for any graphics |

The 5th Generation Intelligent Vision System

› Camera up to 25 FPS, one time calibrate for work.

› Professional light sources, red and white light convert freely, equipped with cooling systems.

› Up to 100 graphics multimode processing, multi-layer settings for half-cut and full-cut.

› Precise joint identify cutting for large graphics.

› Support extra assembly on any Golden Laser machine.

Multi-templates Feature Points Positioning Cutting

Multi-templates Feature Points Positioning Cutting

› Suitable for positioning cutting of various small size patterns

› It can set positioning template of the whole pattern or partial pattern

› Supported not more than 100 graphics cutting at the same time and no limitation on angles.

Mark Point Positioning Cutting and Joint Identify Cutting

› Suitable for oversized graphics or printed garment pattern cutting.

› No limitation on graphic size, shape or marshalling sequence.

› Oversized pattern profile can be extracted through precise joint shooting.

› You can choose any two points of pattern as the Mark Point.

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for , The product will supply to all over the world, such as: Canada, Pretoria, Moscow, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.