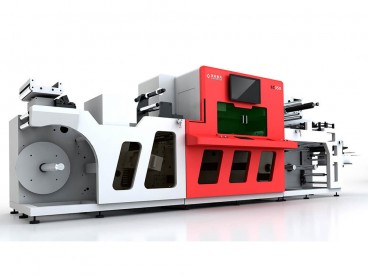

Roll-to-Part Sticker Laser Cutting Machine

Model No.: LC350

Introduction:

This Roll-to-Part Laser Die Cutting Machine includes an extraction mechanism that separates your finished sticker items onto a conveyor. It works well for label converters who need to full cut labels and components as well as extract the finished cut parts. Typically, they are label converters that handle orders for stickers and decals.You have access to a wide range of add-on converting options to improve your label applications. Roll-to-Part Laser Die Cutting System from Goldenlaser is now essential for success in the label manufacturing sector.

This Laser Die Cutting Machine is capable of handling not only roll-to-roll labels, but can also operate as a roll-to-sheet and roll-to-part finishing solution. It includes an extraction mechanism that separates your finished sticker items onto a conveyor. It works well for label converters who need to full cut labels and components as well as extract the finished cut parts. Typically, they are label converters that handle orders for stickers and decals. You have access to a wide range of add-on converting options to improve your label applications. The Goldenlaser’s Roll-to-Part Laser Die Cutting System is now essential for success in the label manufacturing sector.

Through continuous technical advancement and the implementation of software integration solutions, Goldenlaser has established itself as the industry's preeminent provider of laser die cutting solutions. Label converters all around the world are continuing to reap the advantages of Goldenlaser's laser die cutting solutions, which include improved profit margins, enhanced cutting capabilities, and remarkable production rates. Goldenlaser's digital laser cutting systems deliver full automation for label manufacturing, which reduces the operator's workload and simplifies even the most difficult assignments.

Watch roll-to-part laser cutting of sticker in action!

Modular Multifunctional Integration

Modules and add-on converting options of Goldenlaser’s laser die cutting machine

Laser cutting systems can be custom-built by Goldenlaser with your preferred add-on converting options. The modular alternatives listed below may provide versatility to your new or current product lines while also boost your label applications:

Technical Specifications

Main technical parameters of the 2 standard models of roll-to-part laser die cutter

| Model No. | LC350 |

| Max Web Width | 350mm / 13.7” |

| Max Width of Feeding | 370mm |

| Max Web Diameter | 750mm / 23.6” |

| Max Web Speed | 120m/min (depending on laser power, material and cut pattern) |

| Laser Source | CO2 RF laser |

| Laser Power | 150W / 300W / 600W |

| Accuracy | ±0.1mm |

| Power Supply | 380V 50Hz / 60Hz, Three phase |

Applications

Typical applications of Goldenlaser's laser die cutting machine

Many of our customers now have possibilities in both new and current markets thanks to laser converting systems from Goldenlaser. Typical applications include:

Sticker Laser Cutting Samples

For more information on how Goldenlaser can provide a laser cutting solution for your specific needs, please contact us by filling out the ‘Contact Form’ below.

LC350 laser die cutting machine technical parameters

| Max Cutting Width | 350mm / 13.7” |

| Max Width of Feeding | 370mm / 14.5” |

| Max Web Diameter | 750mm / 29.5” |

| Max Web Speed | 120m/min (Depending on laser power, material and cut pattern) |

| Accuracy | ±0.1mm |

| Laser Type | CO2 RF laser |

| Laser Beam Positioning | Galvanometer |

| Laser Power | 150W / 300W / 600W |

| Laser Power Output Range | 5%-100% |

| Power Supply | 380V 50Hz / 60Hz, Three phase |

| Dimensions | L3700 x W2000 x H 1820 (mm) |

| Weight | 3500KG |

| Model No. |

LC350 |

LC230 |

| Max Cutting Width |

350mm / 13.7” |

230mm / 9” |

| Max Width of Feeding |

370mm / 14.5” |

240mm / 9.4” |

| Max Web Diameter |

750mm / 29.5” |

400mm / 15.7 |

| Max Web Speed |

120m/min |

60m/min |

|

(Depending on laser power, material and cut pattern) |

||

| Accuracy |

±0.1mm |

|

| Laser Type |

CO2 RF laser |

|

| Laser Beam Positioning |

Galvanometer |

|

| Laser Power |

150W / 300W / 600W |

100W / 150W / 300W |

| Laser Power Output Range |

5%-100% |

|

| Power Supply |

380V 50Hz / 60Hz, Three phase |

|

| Dimensions |

L3700 x W2000 x H 1820 (mm) |

L2400 x W1800 x H 1800 (mm) |

| Weight |

3500KG |

1500KG |

The main sectors for our laser die-cutting machine include:

Labels, abrasives, automotive, aerospace, composites, electronics, gaskets, medical, packaging, plastics, and self-adhesive tapes.

| Labels | Automotive | Abrasives |

|

|

|

| Self-Adhesive Tapes | Electronics Sector | Gaskets |

|

|

|

| Plastics | Aerospace/Composites | Medical Sector |

|

|

|

Please contact us for more information. Your response of following questions will help us recommend the right machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your end product?