- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

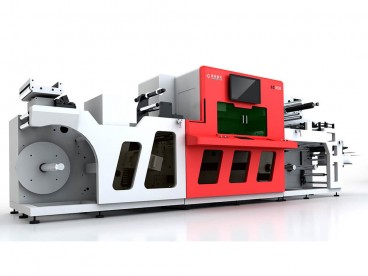

Roll to Roll Laser Cutter for Abrasive Materials

Model No.: LC800

Introduction:

The LC800 Roll-to-Roll Laser Cutter is a highly efficient and customizable solution, specifically designed for cutting abrasive materials up to 800 mm in width. This machine stands out for its versatility, enabling precise cutting of various shapes such as multi-hole discs, sheets, triangles, and more. Its modular design makes it ideal for automating and streamlining abrasive material conversion processes, significantly boosting productivity.

Features of LC800 Laser Die Cutting Machine

The digital laser finisher “roll to roll” for laser cutting and converting.

The LC800 is a powerful and configurable laser cutting machine designed for abrasive materials with a width of up to 800 mm. It is a versatile laser system capable of cutting all possible hole patterns and shapes, including discs with multi-holes, sheets, and triangles. With its configurable modules, the LC800 provides the solution to automate and enhance the efficiency of any abrasives converting tool.

The LC800 can cut a large variety of materials, such as paper, velcro, fiber, film, PSA backing, foam, and cloth.

The working area of the Roll-to-Roll Laser Cutter Series can vary with a maximum material width. For wider materials from 600mm up to 1,500 mm, Golden Laser offers the series with two or three lasers.

There is a wide range of laser power sources available, varying from 150 watts to 1,000 watts. The more laser power, the higher the output. The coarser the grid, the more laser power is needed for a high cut quality.

The LC800 benefits from the powerful software control. All designs and laser parameters are stored in automated databases, making the LC800 very easy to operate. One day of training is sufficient to operate this laser machine. LC800 enables you to process a wide range of materials and cut an unlimited selection of shapes and patterns while cutting the material 'on the fly.'

LC800 Roll to Roll Laser Cutter Workflow

A roll of abrasive material is loaded on the pneumatic unwinder shaft. From the splice station the material is transported automatically into the cutting station.

In the cutting station, two laser heads operating simultaneously to first cut the multi-holes and then separate the disc from the roll. The entire cutting process runs continuously 'on the fly'.

The discs are then transported from the laser processing station to a conveyor where they are dropped into a hopper or palletised by a robot.

In the case of discrete discs or sheets, the trim material is stripped off and wound onto the waste winder.

Watch Laser Cutting of Sanding Discs in Action!

Roll to Roll Laser Die Cutter for Abrasives with Dual Laser Heads

The advantages of the LC800 Roll to Roll Laser Cutter are:

Specifications

| Model No. | LC800 |

| Max. Web Width | 800mm / 31.5" |

| Max. Web Speed | Depending on laser power, material and cut pattern |

| Accuracy | ±0.1mm |

| Laser Type | CO2 RF metal laser |

| Laser Power | 150W / 300W / 600W |

| Laser Beam Positioning | Galvanometer |

| Power Supply | 380V three phase 50/60Hz |