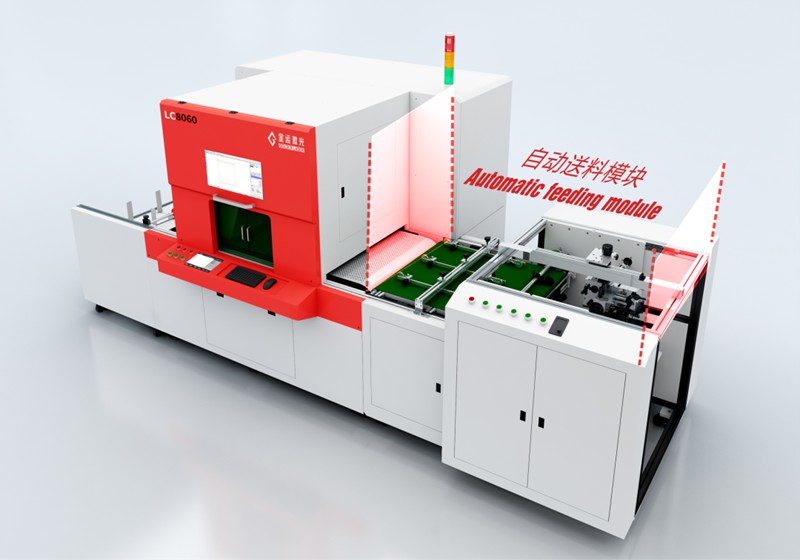

Sheet Fed Laser Cutting Machine

Model No.: LC8060 (Dual Head)

Introduction:

LC8060 sheet fed laser cutter features continuous sheet loading, laser cutting on-the-fly and automatic collection working mode. The steel conveyor moves the sheet continuously to the appropriate position under the laser beam with no stop or start delay between sheets. Eliminating the time and cost of making dies, it is ideally suited to sheet labels, custom shaped cards, prototypes, packaging, carton, etc.

- Enhanced productivity

- Toolless Cutting

- Remove layout constraints

- Decreased costs for scrap materials

- Task reloading in minutes

Sheet Fed Laser Die Cutting Machine

Goldenlaser designs and manufactures high speed and intelligent sheet fed laser die-cutting system that brings innovative and versatile laser die cutting solutions.

LC8060 Sheet Fed Laser Cutter features continuous sheet feeding, dual head laser cutting on-the-fly and automatic collection working mode. The steel conveyor moves the sheet continuously to the appropriate position under the laser beam with no stop or start delay between sheets. LC8060 is ideal for sheet label cutting and other jobs requiring die cutting, kiss cutting as well as creasing. Eliminating the time and cost of making dies, it is ideally suited to short-run labels, custom shaped cards, prototypes, packaging, carton and other projects that would normally require more expensive mechanical dies.

Laser Cutting Module

Self-developed special vision software with high-definition industrial cameras to read barcodes for jobs changeover.

Single, dual or multi-head lasers can be selected according to processing efficiency requirements and material characteristics. The type and power of the laser can be customized and selected on demand.

Features

Specification

| Model | LC8060 |

| Design type | Sheet fed |

| Max cutting width | 800mm |

| Max cutting length | 600mm |

| Accuracy | ±0.1mm |

| Laser type | CO2 laser |

| Laser power | 150W / 300W / 600W |

| Dimensions | L4470 x W2100 x H1950(mm) |

Watch Sheet Fed Laser Cutter LC8060 Working in Action!

Technical Parameters of Sheet Fed Laser Cutting Machine LC8060

| Model | LC8060 |

| Design type | Sheet fed |

| Max cutting width | 800mm |

| Max cutting length | 600mm |

| Accuracy | ±0.1mm |

| Laser type | CO2 laser |

| Laser power | 150W / 300W / 600W |

| Dimensions | L4470 x W2100 x H1950(mm) |

→ LC350 Laser Die Cutting Machine (Roll-to-Roll or Roll-to-Sheet or Roll-to-Part)

→ LC230 Laser Die Cutter (Roll-to-Roll or Roll-to-Sheet or Roll-to-Part)

Applicable material

Glossy paper, coated paper, self adhesive paper, kraft paper, fluorescent paper, pearlescent paper, cardstock, PET, BOPP, PP, plastics, vinyl, foils, leather, fabric, etc.

Applicable industry

Printing & Packaging, RFID, Automotive, Membrane Switches, Abrasive Materials, Industrial, Gaskets, Flexible Circuitry, etc.

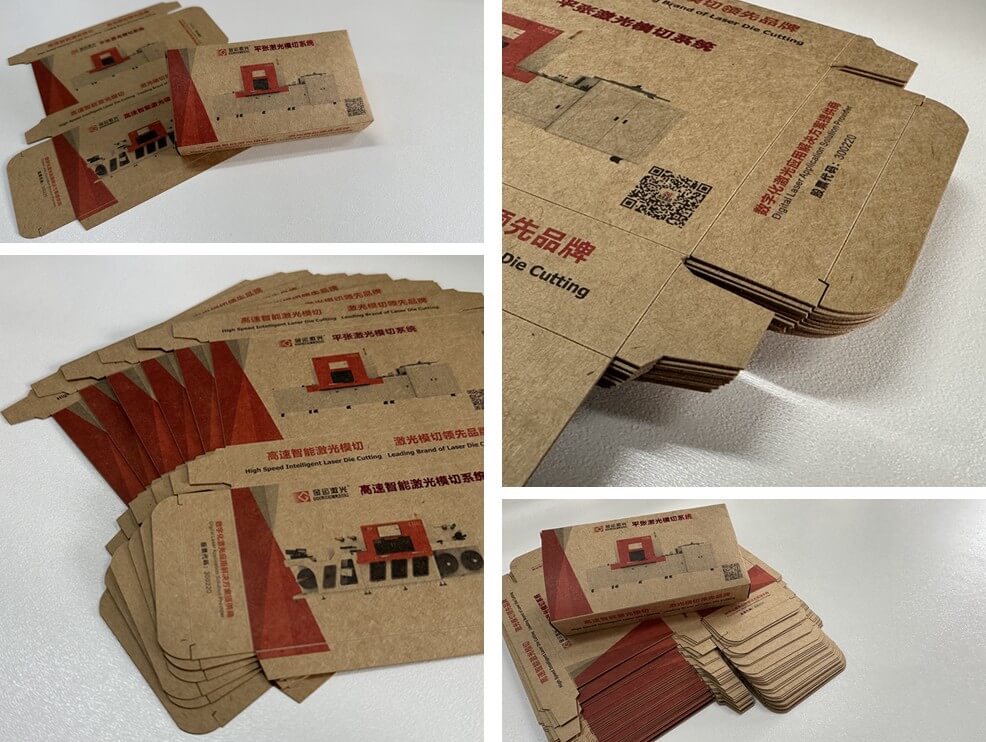

Sheet Fed Laser Cutting Samples – Paper Cartons

Sheet Fed Laser Cutting Samples – PET Cartons

Please contact goldenlaser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What specific material do you need to laser cut? What is the size and thickness?

2. What is your application industry?