Metal laser yekucheka, iyo inoshamisa maindasitiri runako!

Metal laser processing, inongoda kugadzira magiraidhi pakombuta, unogona kugadzira iyo yaunoda magirafu nekukasira, iine mabhenefiti emifananidzo isina muganho, saizi uye kudzika kunogadziriswa, kurongeka kwepamusoro, kukurumidza, kutsetseka uye kusununguka-kusina, "hapana kubata" - hapana kupwanya. zvinhu. Laser processing yave mubatsiri anokosha weindasitiri yekugadzira simbi, uye yakawana zvakakosha zvehupfumi nemagariro.

Laser Engraving

Kubva pane CNC yekudzora tekinoroji, ine laser senge yekugadziridza svikiro, laser etching pane izvo zvinhu, ichisiya yakanaka tsoka.

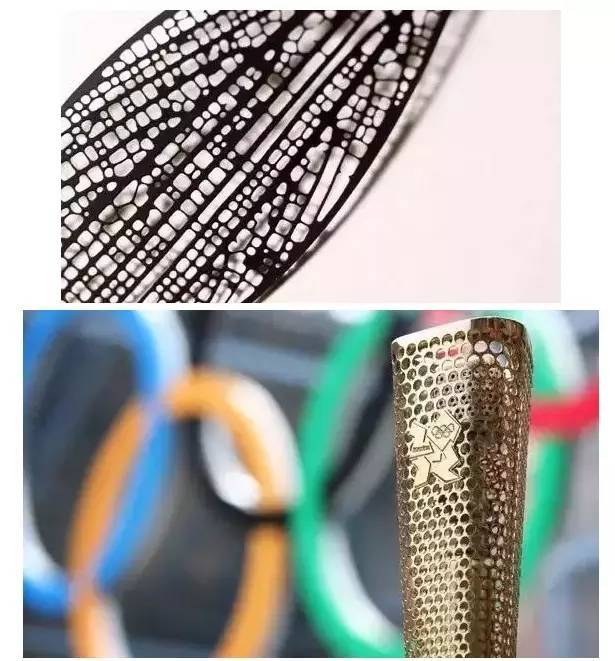

Laser hollowing

Laser hollow inotaridza iyo matatu-dimensional uye yakadzama pfungwa yesimbi, zvekuti inoburitsa yakasarudzika tekinoroji uye hunyanzvi hwekukwezva.

Indasitiri Applications

1. Craft chipo

Nekuda kwekugadzirwa kwesimbi kwakaoma, iyo yapfuura simbi craft inodhura zvakanyanya. Kuuya kwemidziyo yelaser, haingoite kuti simbi yesimbi ivandudze kugadzirwa, kuderedza mutengo, uye kuita kuti ive inokwanisika "matoyi".

2. Magonhi nekushongedza kweWindows

Magonhi esimbi nemafafitera echinyakare anotonhora uye asina kujeka. Iyo laser yekucheka hollowing zvinhu mukushongedza kwekuvaka, magonhi nemahwindo zvinogara zvichichinja, zvichipa kunzwa kunofadza.

3. Zvishongo zvemwenje

Yakanakisa uye inoyevedza laser hollow mitsara, yakasanganiswa nehunyanzvi hwejometri mapatani esimbi yakavharwa, kuitira kuti mwenje wesimbi uwane pekutangira kwerunako.

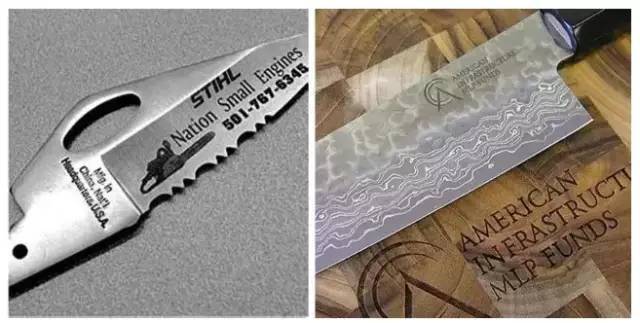

4. Banga

Laser kumaka pane simbi banga maturusi kuita kuti kuwanikwa kushandiswa kunogonawo kukosheswa.