Mashiinka Goynta Laser-Laser-goynta CO2 Mashiinka Goynta Laser

Sida soo saaraha mashiinka goynta laser, Golden Laser waxay bixisaa naqshadaynta, wax soo saarka, bixinta, adeegga iibka ka dib iyo xalalka farsamada.

LAASERKA DAHABKA AH - CO2 sariir lehMashiinka Goynta LaserAstaamaha

I. Mashiinka Goynta Laser Visionloogu talagalay Dhar-Sublimation Dharka Isboortiga, Dharka baaskiilka, Dharka dabaasha, boorarka, calanka

LAASERKA DAHABKA AH – Mishiinka Goynta CO2 ee fidsan

Mashiinka goynta laser Vision waa mid ku habboon jarida daabacaadda dhijitaalka ah ee sublimation dhar-dhareedka dhammaan qaababka iyo cabbirrada. Kamaradu waxay baadhaan dunta, ogaadaan oo aqoonsadaan konturrada daabacan, ama waxay soo qaadaan calaamadaha diiwaangelinta oo waxay gooyaan naqshadaha la doortay iyagoo leh xawaare iyo saxnaan. Gaadhi-qaade iyo feedhiyaha otomaatiga ah ayaa loo isticmaalaa si loo sii gooyo si joogto ah, wakhtiga loo badbaadiyo loona kordhiyo xawaaraha wax soo saarka.

√ Quudinta tooska ah √ iskaanka duulista √ Xawaaraha sare

→Baadh (ogaanshaha iyo garashada) duub duuban oo dhar ah oo xisaabta ku dar wixii dhimis ah ama qalloocan taas oo dhici karta inta lagu jiro habka sublimation oo si sax ah u gooyay naqshad kasta.

●Sawirka duulista qaab weyn.Waxay ku kacaysaa kaliya 5 ilbiriqsi si loo aqoonsado goobta shaqada. Iyadoo lagu quudinayo dharka maro-qaadiyaha dhaqaaqa, kamarada waqtiga-dhabta ah waxay si degdeg ah u aqoonsan kartaa garaafyada daabacan waxayna natiijada u gudbin kartaa gooyaha laysarka. Ka dib marka la gooyo dhammaan goobta shaqada, habka ayaa lagu soo celin doonaa iyada oo aan faragelin gacanta ah.

●Ku wanagsan la macaamilka sawirada kakan.Garaafyada ganaaxa iyo faahfaahsan, software-ku wuxuu soo saari karaa garaafyada asalka ah iyadoo loo eegayo booska dhibcaha calaamadda wuxuuna samayn karaa goyn. Saxnimada goynta waxay gaartaa ±1mm.

● Ku fiican goynta dharka fidsan.Si toos ah u xidhidhiyaha Goynta cidhifku waa nadiif, jilicsan oo siman oo leh sax sare.

II.Mashiinka Goynta Laser ee DharkaGoynta Codsiga Warshadaha

•Dufcadaha dhexdhexaadka ah & kuwa yar yar iyo noocyada kala duwan ee wax soo saarka dharka, gaar ahaan ku habboon dharka gaarka ah.

•Ku habboon jarista noocyada kala duwan ee dharka. Goynta naqshad kasta oo garaafyo ah. Cidhifyada goynta siman oo sax ah. Cidhif xidhan Ma jiro gees guban ama jaban. Tayada goynta heer sare ah.

•Ku wareeji miiska shaqada oo leh nidaamka quudinta tooska ah (ikhtiyaar), xaqiiji quudinta joogtada ah iyo goynta wax soo saarka tooska ah.

•Qaab-dhismeedka dhidibka-Y-da oo laba-laaban Jidka iftiinka laysarka ee duulaya. Nidaamka gawaarida ee Servo, goynta xawaaraha sare. Nidaamka goyntani wuxuu samayn karaa buul dheeri ah oo dheeri ah iyo qaab buuxa oo isdaba-joog ah oo auto-quudinta iyo jarista hal qaab oo ka sarreeya aagga goynta mashiinka.

•Buug-gacmeedka gaarka ah iyo qaabeynta is-dhexgalka tooska ah ee tooska ah wuxuu u shaqeeyaa, hagaajinta isticmaalka walxaha ilaa xad. Waxa kale oo ay leedahay qaab-samaynta, sawir-qaadista, iyo hawlo qiimayneed, habboon oo la taaban karo.

•Mashiinka goynta laser-ka waxaa lagu qalabeyn karaa qaab weyn oo aqoonsi auto-aqoonsi ah iyo nidaamka projector ee goynta saxda ah iyo goynta gaarka ah.

III.Shaandhee Medias, Wershadaha Wershadaha & Codsiga Goynta Laser-ka Farsamada

Goynta laser waxay aad ugu habboon tahay warbaahinta shaandhada. Si loo daboolo shuruudaha gaarka ah ee ku saabsan goynta shay, GOLDENLASER waxay bixisaa noocyo kala duwan oo awood layser ah iyo xalal goynta laser oo dhamaystiran.

●Saxnimada goynta waxay gaari kartaa 0.1mm

●Daawaynta kulaylka, xidhitaanka cidhifyada tooska ah ee cidhifka goynta siman

●La heli karo si loo dejiyo xilliga isticmaalka cidhifka maro iyadoo loo eegayo shuruudaha isticmaalaha.

●Calaamadee qalinka iyo laysarka beddelka tooska ah, dhammaystir habka feerashada, calaamadaynta iyo goynta hal tallaabo.

●Naqshad garaafyo caqli leh iyo software buul leh, hawlgal fudud, oo diyaar u ah jarista qaabab kasta.

●vacuum adsorption miiska shaqada, si fiican u xalliso dhibaatada diirimaad cidhifyada marada.

●Suunka qaadaha birta ah, oo leh nidaam quudin joogto ah iyo nidaam ururin, waxtar sare leh.

●Qaab dhismeedka si buuxda u xidhan si loo hubiyo in boodhka goyntu aanu daadan, ku haboon in lagu shaqeeyo dhirta wax soo saarka degdega ah.

IV.Buulka Maqaarka iyo Nidaamka Goynta Laser-kaDaboolka Kursiga Baabuurka, Bacaha, Kabaha

Xidhmada Nidaamka Goynta Maqaarka -Xidhmada buulka maqaarka oo ka kooban qaybaha soo socda:Moodooyinka/Amarrada Hargaha, Buul-saarka caadiga ah, Digitizing maqaarka iyo Maqaarka Goynta & Ururinta.

Faa'iidooyinka

•Habka laser-ku waa dabacsan yahay oo habboon. Ka dib dejinta qaabka, laser wuxuu bilaabi karaa inuu shaqeeyo.

•Cidhifyada goynta jilicsan. Ma jiro cadaadis farsamo, ma laha qallafsanaan. Ma jiro caaryo loo baahan yahay Habaynta laser waxay badbaadin kartaa kharashka wax soo saarka caaryada iyo wakhtiga diyaarinta.•Tayada goynta wanaagsan. Goynta saxda ah waxay gaari kartaa ilaa 0.1mm. Iyadoon wax xaddidaad ah lahayn.

Tilmaamaha Mashiinka

•Gaar ahaan ku habboon goynta maqaarka dhabta ah.

•Waa set dhamaystiran oo wax ku ool ah oo ah habka goynta laser maqaarka dhabta ah, oo leh nashqada digitizing, nidaamka aqoonsiga iyo software buul. Heer sare oo otomaatig ah, hagaajinta waxtarka iyo kaydinta alaabta.

•Waxa ay qabataa hab sax ah oo sax ah oo digitizing ah kaas oo si sax ah u akhrin kara jaan-goynta maqaarka kana fogaan kara aagga liidata oo si toos ah buul uga samayn kara qaybo muunad ah (isticmaalayaasha sidoo kale waxay isticmaali karaan buul gacan-qabsi ah).

U fududee habka adag ee goynta maqaarka dhabta ah ilaa afar tallaabo

| Hubinta maqaarka | Akhrinta Hargaha | Buul | Goynta |

V. Dharka alaabta guriga, Dharka-korka, Saloofada, Codsiga Goynta Laser-ka

●Lagu dabaqay fadhiga fadhiga, joodariga, daahyada, barkimada dharka alaabta guriga iyo warshadaha dharka. Goynta dharka kala duwan, sida dhar fidsan, polyester, maqaar, PU, cudbi, xariir, badeecooyin dheeri ah, xumbo, PVC iyo walxo isku dhafan, iwm.

●set Full of xal goynta laser. Bixinta digitizing, nashqada muunada, samaynta calaamadaynta, goynta joogtada ah iyo xalalka ururinta. Mashiinka goynta laser-ka dhijitaalka ah oo dhamaystiran wuxuu bedeli karaa habka habraaca dhaqameed.

●Badbaadinta alaabta. Software samaynta sumadeeyaha waa sahlan tahay in lagu shaqeeyo, xirfad-samaynta sumadeeyaha tooska ah. 15 ~ 20% walxaha waa la badbaadin karaa. Looma baahna calaamadiye xirfad leh.

●Yaraynta foosha. Laga soo bilaabo naqshadeynta ilaa goynta, kaliya u baahan hal hawlwadeen si uu ugu shaqeeyo mashiinka goynta, badbaadinta qiimaha shaqada.

●Goynta laser, saxnaanta sare, cirifka goynta qumman, iyo goynta laser waxay gaari kartaa naqshad hal abuur leh. Habaynta aan xidhiidhka ahayn Meesha Laserku waxay gaadhaysaa 0.1mm. Habaynta leydi-xagal, godan iyo garaafyo kale oo adag.

VI. Baarashut, Paraglider, Sailcloth, Codsiga Goynta Laser-ka

● Qaab dhismeedka qaanso-roobaadka ee rukhsadda leh, wuxuu ku takhasusay qaab dhismeed ka ballaaran.

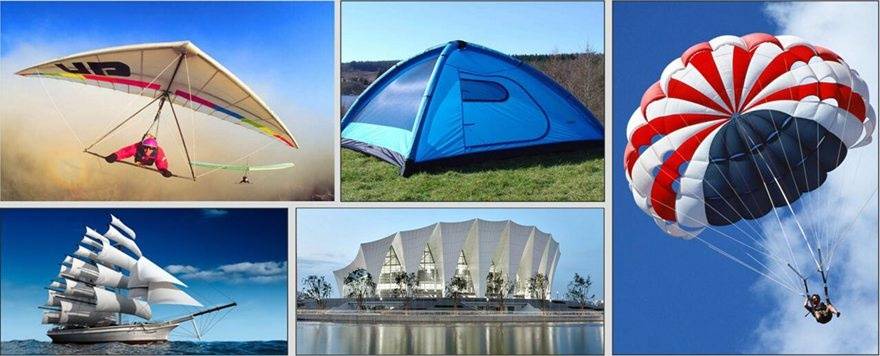

● Loogu talagalay in lagu gooyo boorarka bannaanka, baarashuudka, paraglider, teendhooyin, marada shiraaca, alaabta la buufin karo. Ku habboon jarida PVC, ETFE, PTFE, PE, maro suuf ah, maro Oxford, naylon, nonwoven, PU ama alaabta daahan AC, iwm.

● Automation Nidaamka quudinta otomaatiga ah, suumanka qaada vacuum iyo ururinta miiska shaqada.

● Walax-dheer goyn joogto ah. Awood u leh inuu gooyo 20m, 40m ama xitaa sawirro dheer.

● Badbaadinta shaqada. Laga soo bilaabo naqshadeynta ilaa goynta, kaliya u baahan hal qof si uu u shaqeeyo.

● Kaydinta alaabta. Software-ka calaamadeeyaha-saaxiibtinimada leh, badbaadinaya 7% ama agab ka badan.

● Fududee habka. Isticmaalka badan ee hal mashiin: goynta dharka laga soo bilaabo duub ilaa gabal, calaamadinta nambarka qaybaha, iyo qodista, iwm.

● Mashiinadan taxanaha ah ee laysarka si loo gaaro goynta hal maro ama goynta badan ayaa si guul leh loogu isticmaalay wax soo saarka tirada badan.

| LAASERKA DAHABKA AH - CO2 Habaynta Mashiinka Goynta Laser Flatbed | ||

| Aagga Goynta(aqbal habaynta) |

|

|

| Shaxda Shaqada | Vacuum adsorption conveyor miiska shaqada | |

| Nooca Laser | CO2 DC tube laser galaas / CO2 RF biraha laser tube | |

| Awoodda leysarka | 80W ~ 500W | |

| Software | GOLDENLASER Software-ka goynta, Naqshadeeye Naqshadeeyaha CAD, Calaamadaha Auto, Software-ka calaamadeeyaha, Nidaamka Digitizing maqaarka, VisionCUT, nidaamka sawir-qaadista sambalka | |

| Si Toos ah u Dhan | Gear feeder (ikhtiyaar), hagaajin nidaamka quudinta weecan (ikhtiyaar) | |

| Ikhtiyaari | Meelaynta iftiinka cas (ikhtiyaar), qalin calaamadee (ikhtiyaar) | |