- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

Mashiinka dharka la jeexjeexay ee xargaha gacanta

Moodel Maya.: JycCG / Jyccjg taxanaha

Hordhac:

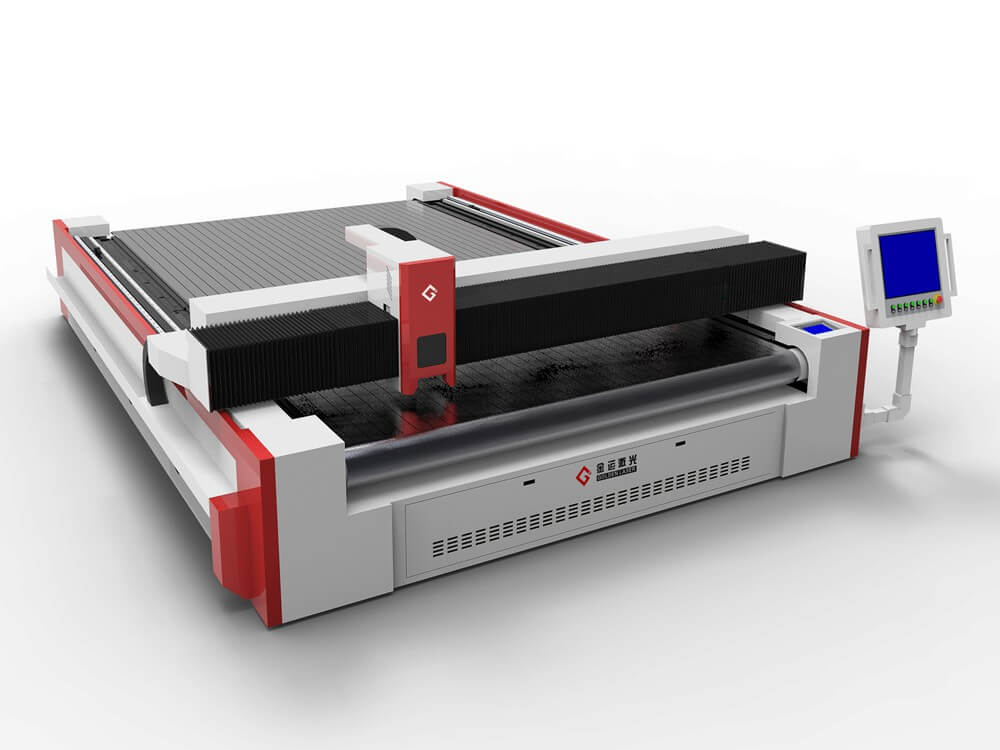

- Mashiinkan The The The The The TE2 flatded leybed lesbed lesbed-ka laseed ayaa loogu talagalay in lagu duubto dharka oo dhan iyo qalab jilicsan si otomaatig ah oo si isdaba joog ah loo jaray.

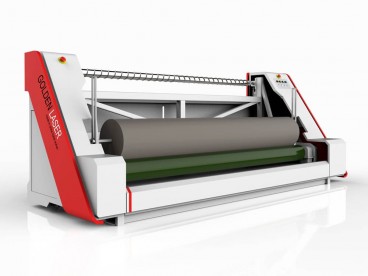

- Waxaa kaxeeyey qalabka iyo xarkaha leh gawaarida spoo, curcurka laser wuxuu bixiyaa xawaaraha ugu sarreeya iyo dardargelinta.

- Xirmooyinka softiweerka iyo xulasho dheeraad ah ayaa la socda nidaamka goynta laser-ka ah waxaa la siiyaa si loo gaaro howsha dijitaalka iyo caqliga leh.

Qalabka gogosha laxanka ee Co2 ayaa loogu talagalay in loo yaqaan 'lesbs lesbs leser' loogu talagalay in lagu duubo dhar-xirta oo ballaaran iyo qalab jilicsan si otomaatig ah oo si isdaba joog ah loo jaray. Ay kaxeeyaanGear iyo Racklaserso matoorXakamaynta, Mashiinka Goynta Laser wuxuu bixiyaa sax sax ah oo tayo sare leh xawaaraha goynta ugu sarreeya iyo dardargelinta. Mashiinka laser goynta laser waxaa lagu heli karaa awood jilicsan oo laga bilaabo 150 Watka ilaa 800 Watta. -Ga / -daMiiska goynta qaabka goyntawaxaa lagu dabaqi karaa inta badan duub dharka dharka caadiga ah.

Iyada oo ay ikhtiyaar u tahayauto-quude, Qalabka duudduuban waxaa lagu quudiyaa miiska goynta si toos ah loona jaro si isdaba joog ah. Mashiinka ayaa la jiranuugista faaruqahoosta ka hooseeyala gudbiyoShaxda Shaqada ah, oo hubisa in agabku miiska dul fadhiyo. Kala duwanNidaamka HimiladaWaxaa lagu qalabeyn karaa mashiinkan laser ee loogu talagalay arjiyada kaladuwan sida kuraas dheelitiran oo daabacan oo daabacan. Iyo Mark Pen ama Furninta Jet-Jet ee Jeup-ka ayaa la heli karaa si loogu sameeyo calaamadaha tolidda ama ujeedo kale.

Astaamaha mashiinka

Tilmaamaha waxqabadka sare ee loo yaqaan 'Claser Teced Mashiinka Laser'

•WaxanMashiinka goynta leserWaxay bixisaahawlgal dhakhso leh oo aad u sax ahWaad ku mahadsan tahay qaybaha tayo sare leh.Si aad ah loo ku tiirsan yahay iyo dayactir bilaash ah.

Nidaamka wadista darawalnimada ee sare iyo nidaamka wadista.Iyada oo leh tuubbada la dhisayo ee korantada leh, oo xawaare ku socda ilaa 1,200mm / s, dardargelinta illaa 8,000mm / s2, waxayna ilaalin kartaa xasilloonida muddada-dheer.

Jabbaan YaassAwa serso matoor

- Hubso in saxda ah ee saxda ah, isku halaynta, iyo waxqabadka.

•WaxanMashiinka laserla yimaadoNidaamka Conveyor. Mashiinku wuxuu si toos ah u quudiyaa walxaha joogtada ah ee isgoysyada joogtada ah ee isku xirka sariirta oo tirtiraya waqtiga hoos udhaca si loo gaaro wax soosaarka ugu badan ee suuragalka ah ee suurtagalka ah.

Intaa waxaa sii dheer, TheFaafida vacuumShaqada ayaa leh shaqadaAdkeynta cadaadiska cadaadiska tabanSi loo hubiyo in loo yaqaan 'florka suufka inta lagu jiro goynta laser goynta.

• Quudiyeyaasha otomaatigga ahlasixitaanka qalloocaShaqada (ikhtiyaari) si loo hubiyo quudinta saxda ah.

• Buugga gaarka ah iyo is dhexgalka otomaatiga ahkumbuyuutarrada kumbuyuutarkaHawsha ayaa hagaajin karta isticmaalka dharka si aad u xun.

• Oo ay wehelisoNidaamka qiiqa, madaxa laser iyo nidaamka qiiqa la isku daro; Saamaynta daal wanaagsan, si loo hubiyo in boodhku uusan wasakheyn qalabka.

• Waa macquul in la dhammaystiroQaabka oo dhamaxa qaabkan dheeroo leh dherer qalad ah oo ka badan qaabka goynta.

• -Ga / -daNidaamka goynta leser is moobeelaNaqshadeynta sida ay macaamiisha ka baaraandegaan macaamiisha.

Faahfaahin Degdeg ah

| Nooca laser | Co2 bir bir bir ah |

| Awooda laser | 150W 300W 600W 800W |

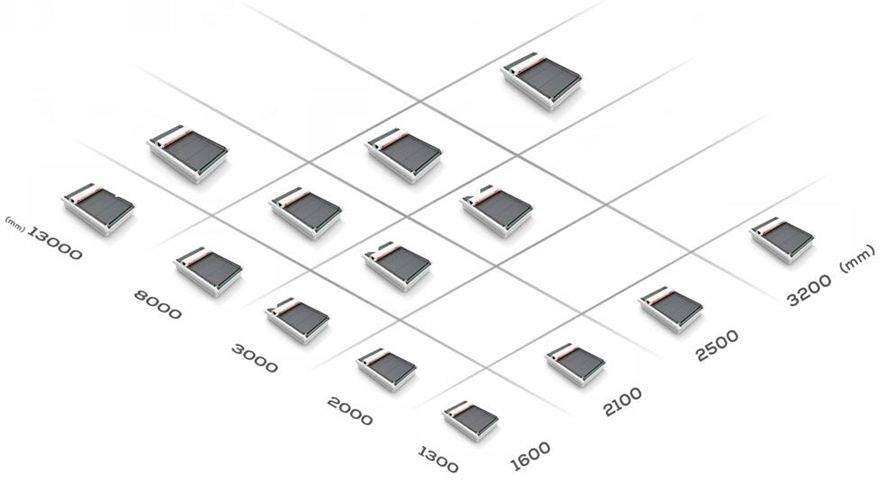

| Goobta shaqada | 2000mm ~ 8000mm (l) × 1300mm ~ 3200mm (w) |

| Shaxda Shaqada | Miis-ka-aruumka FACUUM |

| Nidaamka Dhaqdhaqaaqa | Gudbinta Rack iyo Pinion, Sermo Gawaarida wadista |

| Xawaaraha gooynta | 0 ~ 1,200mm / s |

| Sheelarayn | 8,000mm / s2 |

| Nooca laser | CO2 DC Glat Laser |

| Awooda laser | 150W 300W |

| Goobta shaqada | 2000mm ~ 8000mm (l) × 1300mm ~ 3200mm (w) |

| Shaxda Shaqada | Miis-ka-aruumka FACUUM |

| Nidaamka Dhaqdhaqaaqa | Gudbinta Rack iyo Pinion, Sermo Gawaarida wadista |

| Xawaaraha gooynta | 0 ~ 600mm / s |

| Sheelarayn | 6,000mm / s2 |

Laser goynta shaqada

SIDEE AYAA LACAG LA'AANTA XARUNTA MARKA LASED EE MARKA FARSAMADA?

Waxyaabaha ugu sareeya ee ceas-ka qubka leh

FARSAMADA FARSAMADA FARSAMADA FARSAMADA FARSAMADA IYO kordhinta suurtagalnimada

Daboolka difaaca amniga

Samaynta hawl-galinta saase aamin ah oo yareynaya caloosha iyo boodhka laga yaabo in la soo saari karo inta lagu gudajiro.

Waxaa la heli karaaBuuxaIkhtiyaarka si aad u buuxiso Ilaalinta Alaabada Alaabada Laser ee Laser.

Quudinta baabuurta

Waa unug quudin ah oo ku shaqeeya is-dhexgalka laser goynta leser. Quudiyeyaashu waxay u wareejin doonaan qalabka loo duubo miiska goynta miiska ka dib markaad duubtid liiska quudinta. Waxaad dejin kartaa xawaaraha quudinta kaladuwan iyadoo loo eegayo xawaaraha mashiinka ugu weyn. Q waxtarka leh wuxuu leeyahay dareeraha inuu hubiyo booska saxda ah ee maaddada. Quudiyeyaasha waxaa lagu qalabeyn karaa iyadoo lagu dhejinayo dhexroor dhexroor oo kala duwan oo loogu talagalay duub kala duwan. Roller pneumatic-ka kala duwan ayaa loo isticmaali doonaa dharka lagu xiro oo leh xiisad kaladuwan, dhumucdan ... cutubkani wuxuu kaa caawinayaa inaad garowdo geedi socodka goynta otomaatiga ah ee otomatiga ah.

Nuugista faaruqa

Jadwalka faaruqa ah wuxuu hoos yimaadaa miiska goynta, waxaa jira godad taxane ah oo miiska dushiisa ah oo miiska korkiisa ku jiido dusha sare. Jadwalka faaruqa ah wuxuu oggol yahay inuu si buuxda u helo dusha sare, ma jiraan wax lagu helo jidka jidka laser ee laser-ka halka goynta. Taageerayaasha adag ee daallan, waxay sidoo kale kaa caawineysaa ka hortagga qiiqa iyo boodhka markii goynta.

Nidaamka Himilada

Nidaamka aragtida ayaa ah xulasho muhiim ah markii aad rabto inaad gooyso dusha. Si kasta oo loogu talagalay daabacaadda grobure ama kontoroor, waxaad u baahan doontaa aaladdan si aad u aqriso dusha sare ama xogta gaarka ah ee meelaynta iyo goynta. Sawirka iskaanka ah iyo iskaanka calaamadaha calaamadaha ayaa ku habboon dalab kala duwan. Waxaan bixinaa ikhtiyaarro aragtiyo kaladuwan oo codsiyo kaladuwan ah.

Calaamadeynta cutubyada

1. Mark qalin qalin

Inta badan gogo 'goynta leser goynta, gaar ahaan dharka dharka, waa in la tolo ka dib goynta. Waxaad u adeegsan kartaa qalinka calaamadaynta si aad u sameyso calaamadaha goynta goynta si aad uga caawiso shaqaalaha si aad u tolo tolidda samafalka. Waxa kale oo aad u isticmaali kartaa qalinka calaamadaynta si aad u sameysid calaamado gaar ah oo ku saabsan goynta goynta sida tilmaanta sheyga, cabirka sheyga, taariikhda soo-saarista sheyga iyo iwm ... waxaad dooran kartaa midab midab leh oo ah midabka qalabkaaga.

2. Daabacaadda Jet-jet-jet

Isbarbardhigaya "qalinka Mark" tikniyoolajiyadda daabacaadda-jet-jet waa geedi socod aan taabaneyn, sidaa darteed waxaa loo isticmaali karaa noocyo badan oo kala duwan oo noocyo badan oo kala duwan oo kala duwan. Waxaana jira jaakooyin kaladuwan oo ikhtiyaar ah sida khad kacsan iyo khad aan kacsan, si aad u isticmaasho warshado kala duwan.

Tilmaanta casaanka cas

- Nidaamka Raadinta Laser Laser

Tilmaamuhu Liiska casaanka wuxuu ka caawiyaa sidii loo tixraaci lahaa halka ay ku soo degi doonaan shaygaaga wax lagu aadi doono maaddadaada adoo raaci doona jilitaanka naqshadaada oo aan shaqeynin laser. Iyo sidoo kale meesha aad ka bilowdid.

Labaal madaxa

Laba madax oo laser ah

Labada madax ee laser waxaa lagu dhejiyay isla gaant'da, kaas oo u saamaxaya laba qaab oo isku mid ah in si isku mid ah loo gooyo.

Madax-bannaan oo madaxbanaan

Madaxa madax-bannaan ee madaxa-bannaan waxay yareyn karaan naqshado kala duwan isla waqti isku mid ah. Waxay kordhisaa waxtarka goynta iyo soo-saarista wax soo saarka ee shahaadada ugu weyn.

Madaxa Galvo

Galvo Laser waxay isticmaashaa xawaare sare, muraayadaha gawaarida gawaarida lagu wado si ay ugu hoggaansamaan naser the the the the the the the the the the the the the to lend-ka laser. Waxay kuxirantahay booska gudaha garoonka calaamadaynta laser, dokumku wuxuu saameeyaa sheyga xagal weyn ama ka yar oo rabitaan ah. Cabbirka duulista ee calaamadaha waxaa lagu qeexaa xagasha ka-goynta iyo dhererka focal ee indhaha. Maaddaama aysan jirin qaybo la dhaqaajin karo (marka laga reebo muraayadaha) lo'da laser-ka ah ayaa lagu hagi karaa xasaasiyad aad u sarreysa oo ku habboon oo ku habboon waqtiyada suulka sare iyo calaamadaha tayo sare leh.

Nidaamka kala-sooca otomatiga ah

Heerka sare ee otomatiga inta lagu gudajiro soo dejinta iyo kala-soocidda ayaa sidoo kale dardar gelisa hanaannadaada wax soo saarka ee ku xiga.

Faa'iidooyinka dharka dharka lagu gooyo ee loo gooyo nidaamyada laser ee Dahabka

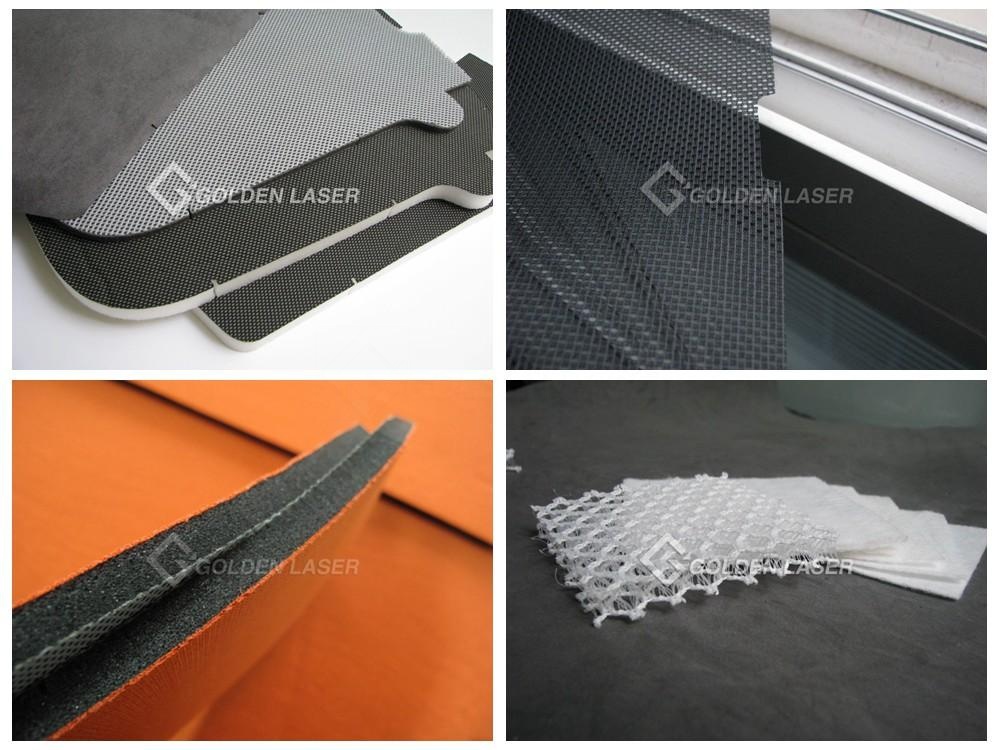

Nadiifinta cidhifyada - gogosha aan lahayn

Laser otomatic wuxuu si otomaatig ah u qorayaa geesaha goynta ah sidaas darteedna, waxay ka hortagtaa in ay fuulmaan. Marka la barbar dhigo goynta farsamada, goynta leysarku wuxuu badbaadiyaa tillaabooyin badan oo shaqo oo ku saabsan howsha dheeriga ah.

Joojinta joogtada ah ee liiska

Laser goynta dharka iyo dharka tooska ah ee duubista ah waxay u mahadcelinayaan nidaamka isku-darka iyo quudyaha otomatiga ah. Awood u leh qaabeynta qaab-dheer ee ultra.

Laser goynta tafaasiisha aad u fiican

Laser wuxuu ku habboon yahay goynta qaab ahaan qaab macquul ah oo adag iyo naqshado, xitaa goynta godad aad u yar (godad laser).