- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

Mashiinka Himilada Laser goynta goynta ee loogu talagalay suuxinta daabacan

Moodel No. CJGV-180120LLD

Hordhac:

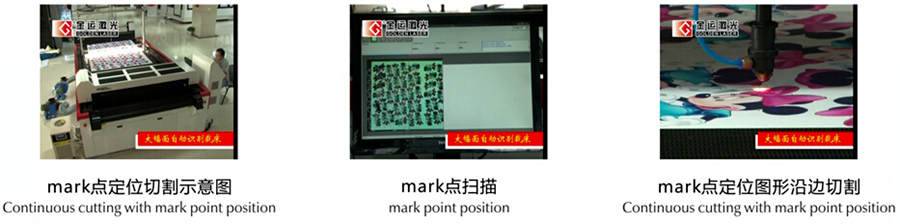

Jarida laser ee lagu dhajinayo nidaamka aqoonsiga aragga wuxuu u adeegaa makiinad goyn oo goyn ah oo laser ah oo loogu talagalay dharka lagu daabaco ee lagu daabaco dharka. Kaamirooyinka Sawir dharka inta lagu gudajiro koritaanka, la garto oo aqoonsado qaababka daabacan ee grontan ama soo qaado calaamadaha diiwaangelinta daabacan, oo u dir macluumaadka goynta mashiinka goynta laser. Hawshani waxay ku celcelinaysaa ka dib markii mashiinku dhammeeyo si loo jaro qaabka hadda jira. Hawsha oo dhan gebi ahaanba si otomaatig ah ayaa loo gartaa.

- Aagga Shaqada:1800mm × 1200mm / 70.8 "× 47.2"

- Aagga Sawirka Kaameeraha:1800mm × 800mm / 70.8 "× 31.4"

- Aagga Ururinta:1600mm × 600mm (63 "× 23.6")

- Awoodda laser:150W, 300W

- Xawaaraha Jarida:0-800 mm / s

-Ga / -daNidaamka Himiladawaa xalka softiweerka / qalabka ah ee loogu talagalay in lagu ogaado / lagu hagaajiyo qaabka iyo booska qaababka iyadoo loo eegayo dharka ku saleysan aqoonsiga indhaha ee ku saleysan aqoonsiga indhaha. -Ga / -daNidaamka Himiladawaxaa lagu dhex daraa mashiin go 'leysar goyn ah waxayna siisaa xalka dabacsan ee codsiyada kala duwan.

Haddii aad ku jirtid warshadahadharka isboortiga,Fashion dhakhso leh, Ganacsiyada Ganacsi, Qurxinta gudaha or Saxeex jilicsan, illaa intaad u baahan tahay baahidaBilimada Dheecaanka daabacan ee Dhameystiran, theHimilada LaserWaxay u adeegtaa sidii nidaam goyn oo laser oo dhammaystiran.

Faahfaahinta

| Goobta shaqada | 1800mm × 1200mm / 70.8 "× 47.2" |

| Aagga Sawirka Kaameeraha | 1800mm × 800mm / 70.8 "× 31.4" |

| Nooca laser | Glass Glass / Co2 bir bir ah |

| Awooda laser | 150W, 300W |

| Shaxda Shaqada | Shaxda Shaqada Concleyor |

| Nidaamka Dhaqdhaqaaqa | Serso matoor |

| Wax-kombiyuutar | Xirmooyinka Softenlaser CAD |

| Fursadaha kale | Quudiyeyaasha gawaarida gawaarida gawaarida gaduudan |

Sidee nidaamka aragtidu u shaqeeyaa?

> Cameras Skaanka dharka lagu jiro inta lagu gudajiro isku-darka,ogaada oo aqoonsada qaababka daabacan or Soo qaado calaamadaha diiwaangelinta daabacan ee daabacan, oo u dir macluumaadka goynta mashiinka goynta laser. Hawshani waxay ku celcelinaysaa ka dib markii mashiinku dhammeeyo si uu u jaro daaqadda goynta hadda jirta. Hawsha oo dhan gebi ahaanba si otomaatig ah ayaa loo gartaa.

> Nidaamka aragtida waxaa lagu waafajin karaa goos goos goos ah oo ka mid ah cabbir kasta; Qodobka kaliya ee kuxiran ballaca goynta ayaa ah tirada kaamirooyinka.

> Waxay kuxirantahay goynta loo baahan yahay in la jaro tirada kaamirooyinka loo kordhin doono / hoos u dhaca. Inta badan codsiyada wax ku oolka ah, 90cm oo ballaadhan oo goyn ah ayaa u baahan 1 kamarad.

On-duulitaanka-duulista ee aqoonsiga aragga

Kor u qaadista heerkaaga wax soo saarka ee nidaamka aragtida. Tikniyoolajigaan laser-ka sareIsla markiiba iska baar waxyaabaha daabacanWax ka qabadka hawl wadeenka, oo aan loo baahnayn in la jaro faylasha.

Ka baaraandegista sare ee dharka daabacan waxay ku kalsoonaan kartaa mashiinka goynta hirarka laser ee laser. Ku raaxayso faa'iidooyinka aShaqo-wadaag otomaatig ah, oo yaraaday xilliyada shaqo la'aanta iyo isticmaalka ugu badan ee wax ugu yar ee qashinka.

Aqoonsiga kamaradda ee-casriga ah waxaa loo isticmaalaa in si dhakhso ah loo iska baaro maaddada oo si otomaatig ah loo abuuro weelasha goynta. Bedel ahaan, astaamaha ayaa si sax ah loogu akhriyi karaa kamaradda, iyagoo u oggolaanaya falanqayntayaga caqliga leh si ay ugu magdhabaan wixii cillado ah. Marka laser la jaro gogosha ka bax mashiinka, si fiican ayey u jareen, marka loo eego qaabeynta. Waqti kasta mar kale.

Tiknoolajiyadda aragga ayaa awood u leh inay si dhakhso leh u baarto maaddada sariirta goynta, si otomaatig ah u abuuro vector gooye oo jarjar liiska oo dhan oo ka dhex-dhexaadin la'aan. Looma baahna in loo baahdo in la abuuro faylal la jaro / Naqshado. Iyada oo keliya dhagsii badhanka, fayl kasta oo naqshadeyn ah oo lagu rakibay mashiinka waxaa lagu gooyn doonaa cidhifyada tayada leh.

Mashiinka goynta aragtida laser-ka waxaa lagu qalabeeyaa isha lesa ee tayada ugu fiican ee laser-ka oo uu ku fiicnaan doono jawiga soosaarka mugga sare.

Conceyor-ka faaruqinta ayaa si sax ah u quudin doona oo yareyn doona qaab kasta oo dherer ah ama naqshad buufin leh oo leh xawaare aan la xarayn.

Ka daawo aragtida Hisoer Laser goynta ficil

Muuqaalka Himilada ee Laser Laser goynta goynta ee ku-meel-gaarka ah ee lagu keydiyo ee lagu daabaco dharka lagu daabaco iyo maaskaro