Metal laser cutting, the stunning industrial beauty!

Metal laser processing, only need to design graphics on the computer, you can make the desired graphics immediately, with advantages of graphics unlimited, size and depth adjustable, high precision, fast, smooth and burr-free, “no contact” – no crush the material. Laser processing has become an indispensable helper of the metal processing industry, and has achieved significant economic and social benefits.

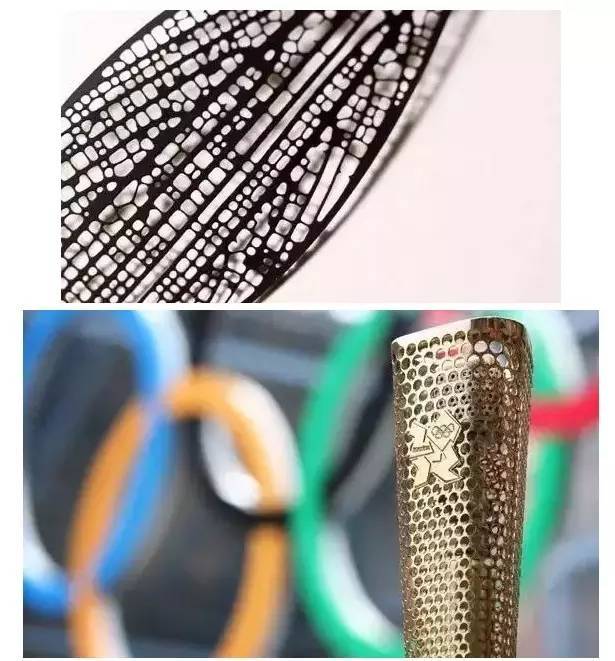

Laser Engraving

Based on CNC control technology, with laser as the processing medium, laser etching on the material, leaving a beautiful footprint.

Laser hollowing

Laser hollow outlines the three-dimensional and solemn sense of metal, so that it exudes a unique technology and artistic charm.

Industry Applications

1. Craft gift

Due to metal processing difficultly, the previous metal craft is very expensive. The advent of laser equipment, not only makes the metal craft improve production efficiency, reduce cost, and make it become affordable “toys”.

2. Doors and Windows decoration

The traditional metal doors and windows are cold and dull. The laser cutting hollowing elements into architectural decoration, doors and windows become ever-changing, giving a pleasing feeling.

3. Lighting ornaments

Elegant and graceful laser hollow lines, coupled with innovative geometric patterns for a simple metal enclosure, so that the metal lighting to find the starting point for the beauty.

4. Knife

Laser marking on the metal knife tools to make it available for use can also be appreciated.