Stainless Steel Laser Cutting for Decoration Industry

As a result of strong corrosion resistance, high mechanical properties, the surface not fade over time, the color with the angle of light having different color changes and other characteristics, stainless steel is widely used in decorative engineering industry. For example, in a variety of top clubs, public recreation places and other local decoration, stainless steel is used as curtain wall, hall wall, elevator decoration, signs advertising, front screens and other decorative materials applications.

However, the stainless steel plate made of stainless steel products is a very complex technical process. The production process requires a lot of processes, such as cutting, folding, bending, welding and other mechanical processing. Among them, the cutting process is a more important process. There are many kinds of stainless steel cutting traditional processing method, but low efficiency, poor quality of molding and seldom meet the needs of mass production.

At present, the stainless steel laser cutting machine - fiber laser cutting machine is widely used in the metal processing industry because of its good beam quality, high precision, small slit, smooth cut, flexible cutting graphics, etc., in the decoration industry is no exception. Here we take a look at the stainless steel laser cutting machine in the decorative industry applications.

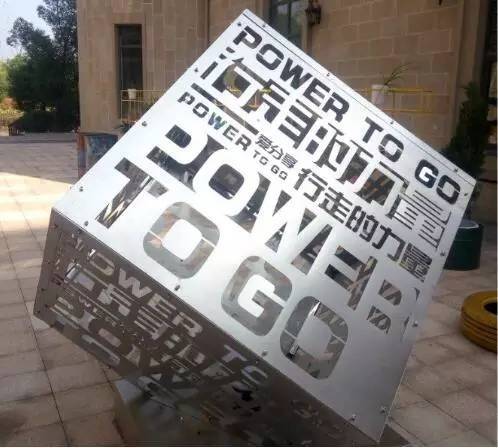

Laser cutting stainless steel screen

Laser cutting stainless steel architectural decoration

Fiber laser cutting machine is constantly improve the high-tech, information technology. Relative to the traditional mechanical manufacturing technology, laser cutting is another revolution, resulting in a huge promoting role for stainless steel decoration engineering industry. With the increasingly fierce market competition, the technology will play an increasingly important role, and bring huge economic benefits.