- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

Auto Feti ea ho fofa ea ho fofa ea ho fofa ea ho fofa ka masela a hatisitsoeng a hatisitsoeng

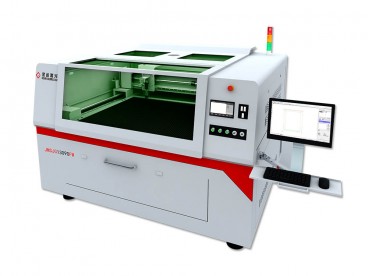

Mohlala no .: CJGV-1801330ld

SELELEKELA:

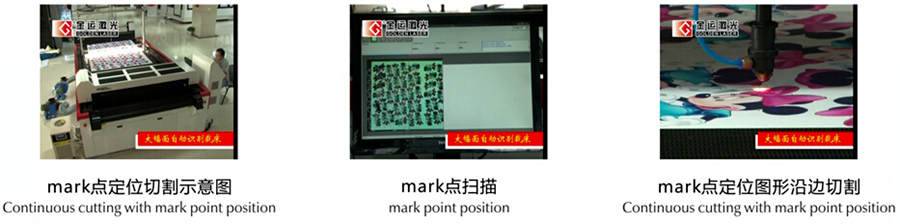

Sistimi ea pono ea pono ke software e ncha e ntlafalitsoeng e thehiloeng tsamaisong ea taolo ea rona ea taolo ea Laser. Mochini o sehiloeng oa Vision laser o ka lemoha ka bohona mme o khaole litšoantšo tse hatisitsoeng ka boselamoneng a hatisitsoeng, kapa ts'ebetsong sebakeng sa metopa e boletsoeng. E sebelisoa haholo liaparong le metsero le lipalesa, li-sportswrel tsa jeme, li-cycling vitat, katse e kholo e hatisitsoeng, jj.

Mochini o sehiloeng oa Visio oa Vision bakeng sa masela a hatisitsoeng a hatisitsoeng

√Ho fepa ka koloi √Ho fofa scan √Lebelo le phahameng √Kananelo e bohlale ea patsi ea lesela le hatisitsoengSistimi ea pono ea pono ke software e ncha e ntlafalitsoeng e thehiloeng tsamaisong ea taolo ea rona ea taolo ea Laser. PonoMochine o sehiloeng oa LaserO ka lemoha ka bohona mme a khaole litšoantšo tse hatisitsoeng ho masela a hatisitsoeng, kapa a sebetsa sebakeng se boletsoeng ho ea ka boemo ba metsero ea lesela. E sebelisoa haholo liaparong le metsero le lipalesa, lipapali tsa lipapali tse hatisitsoeng, tsa folakha, katse e kholo e hatisitsoeng, jj.

• Ho seha tharollo ea ho otlolla masela a hatisitsoeng a hatisitsoeng le ho loma vamp

• Ho seha tharollo ea ho otlolla masela a hatisitsoeng a hatisitsoeng le ho loma vamp

>Kopanya le ho khaola

Molemo: software e ka sekaseka ka kotloloho le ho ntša greetoctor cotour, ha ho hlokahale setšoantšo sa pele.

E loketse ho seha litšoantšo tse hatisitsoeng tse hatisitsoeng ka contour e boreleli.

> Mareka Polelo Boemo le ho Seha

Molemo: Ha ho na moeli ho li-graphics / tse fumanehang ho li-graphics tsa Graphics / tse holimo

• Ho bapisoa le Sistimi ea CCD ea CCD ea CCD

MOTLATSI OA MOTLATSI>Lebelo le phahameng le tšosang, sebaka se seholo se sekaseka.

> Tšoantšiso e iketsa eka pele e tšoantšitse: Ha ho na setšoantšo sa mantlha sa pele.

> E fumaneha ho seha sebopeho se seholo le li-graphic tse ling tse telele.

• Tekanyetso e hatisitsoeng ea fabric

1. Sebopeho se seholo se fofang.Ho nka metsotsoana e 5 feela ho amohela sebaka sohle se sebetsang. Ha u ntse u fepa lesela ke morekisi ea tsamaeang, khamera ea nako ea nnete e ka u thusa ho tseba litšoantšo tse hatisitsoeng ka potlako le ho fana ka liphetho holaser cuttingmochini. Kamora ho kuta sebaka sohle se sebetsang, ts'ebetso ena e tla phetoa ntle le ho kenella ha ho kenella.

2. E ntle ha u cheka litšoantšo tse rarahaneng.Ka mohlala a khaola lintlha. Bakeng sa litšoantšo tse ntle le tse qaqileng tse qaqileng, sokotso li ka holisa litšoantšo tsa mantlha ho latela lintlha tsa lintlha tsa Mareka le ho liha. Ho nepahala ho hoeletsang ho fihlela ± 1mm

3. E ntle ho seha lesela le otlolohileng.Bohale bo bofu bo hloekileng, bo bonolo ebile bo boreleli ka ho nepahala haholo.

4. Tšu ea letsatsi le letsatsi ea mochini o le mong ke liaparo tse 500 ~ 800.