- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

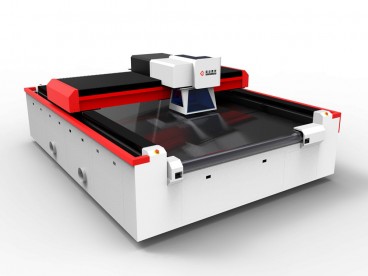

Galvo Laser e sehiloeng le Mochini o Potlatseng Bakeng sa Lesela la Jersey

Model no .: ZJJG (3D) 170200ld

SELELEKELA:

- Mochini o ikhethileng oa laser o ile a kopanya letlapa le kopaneng le phapanyetsano e ka mo phethoang, e lebisang jerssey, polyester, microfiber, e bile e otlolla microfile.

- 150w kapa 300w Rf ea raese ea tšepe ea tšepe.

- Sebaka sa ho sebetsa: 1700mm × 2000mmmm (66.9 "* 78.7")

- Ho tsamaisa tafole ea ho sebetsa ka thepa ea likoloi.

Mochini oa lebelo le phahameng oa pharane le mochine oa gantry oa laser

Mohlala: Zjjg (3D) 170200ld

√ e sehiloeng √ ho khethoa √ e kopanyang

Zjjg (3D) 170200ld ke khetho e ntle bakeng sa papali ea lipapali ea lipapali ea ho khaola ebile ea e nyenyefatsa.

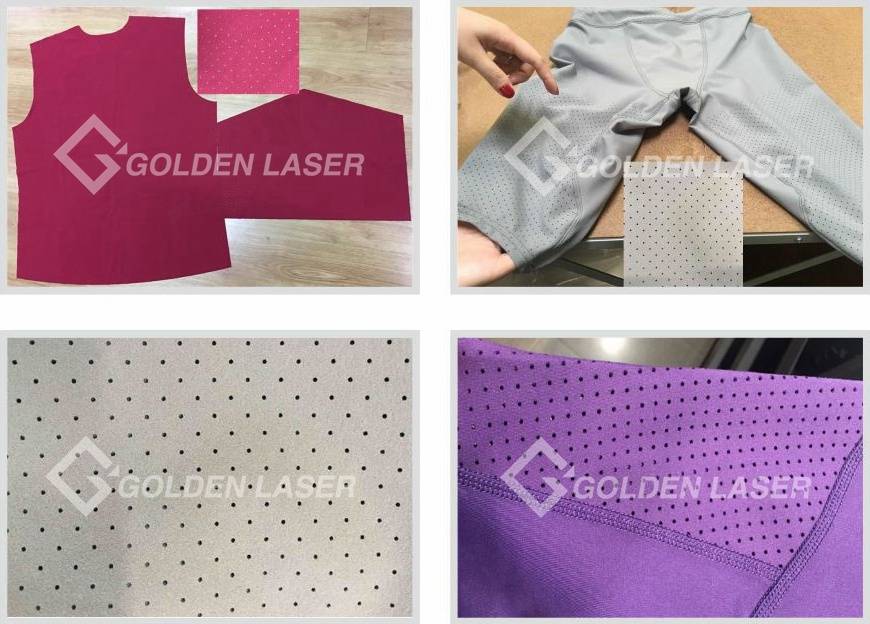

Ho na le mekhoa e 'meli e fapaneng ea ho etsa litšoantšo tsa lipapali le boroko. Mokhoa o le mong oa tloaelehileng ke ho sebelisa masela a lipapali tse seng li ntse li na le masoba a phefumolohang. Likopano tsena li etsoa ha li loma, 'me re li bitsa "masela a pique". Mofuta oa lesela le ka sehloohong ke k'hothone, e nang le sethepu se senyenyane. Ho tlohela mosebetsi le mongobo oa Wicking ha ho monate haholo.

Lesela le leng le sebelisoang haholo le sebelisoang hohle le omella masela a mesh. Hangata hona ke bakeng sa kopo ea lipapali tsa lipapali tsa boemo ba lipapali.

Leha ho le joalo, bakeng sa litšoantšo tse phahameng tsa ho qetela, lisebelisoa li maemong a phahameng haholo, Swandex, ka likhohlano tse phahameng, e phahameng haholo. Masela ana a sebetsang a theko e phahameng haholo ebile a sebelisoa haholo 'me a sebelisoa haholo ka li-jerseys, feshene ea feshene, le mekhoa ea feshene ea feshene, le liaparo tse ngata tse ngata. Mabout a phefumolohang ka kakaretso a entsoe likarolong tse khethehileng tsa jemen tse kang santis tsa seretse, morao, tse khuts'oane, tse khutšoane. Meetso e khethehileng ea feshene ea masoba e boetse e sebelisetsoa ho apara ka bongata haholo.

Likarolo tsa sehlooho

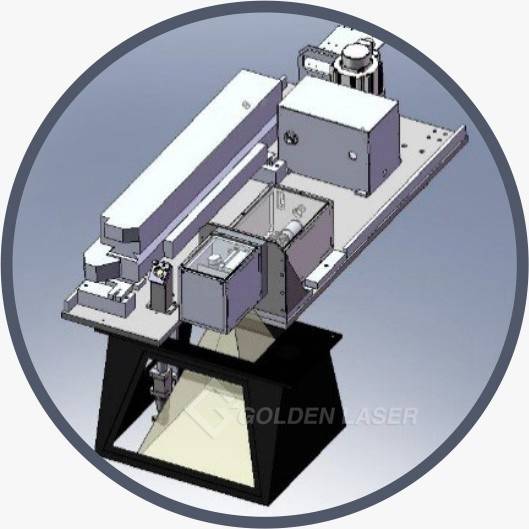

Mochine ona oa laser o kopanya bo-Galvanometer le Xy Gantry, ba arolelanang tube e le 'ngoe. Mo-Galvanoster e fana ka lengolo le lebelo le phahameng haholo, le ho tšoasang, ha Xy Gantry a lumella ho li-patens kamora ho baleha.

Ho tsamaisa tafole ea ho sebetsa ho loketseng ho loketse lisebelisoa ka bobeli ho roll le ka pampiring. Bakeng sa lisebelisoa tsa roll, se fepehileng aumagic se ka hlomelloa bakeng sa mochini o ikemetseng o tsoelang pele.

Papiso ea Galvo Laser, XY Gantry laser & mecharanight e khaolang

| Mekhoa e Khethang | Galvo Laser | Xy gantry laser | Mocha oa ho kuta |

| E hatetseng pele | E bohale bo boreleli, ba tiisitsoeng | E bohale bo boreleli, ba tiisitsoeng | Bohale |

| Hula ka lintho tse bonahalang? | No | No | Ho joalo |

| Lebelo | Phahameng | Butle | Tloaelehileng |

| Mofoko oa Design | Ha ho na moeli | Phahameng | Phahameng |

| Kiss Cutting / Ho tšoaea | Ho joalo | No | No |

Liindasteri tse eketsehileng tsa Ts'ebeliso

- Feshene (stockwear, denim, lieta tsa lieta, mekotla);

- Interior (Litsela, Mats, Li-Cuntint, Sofas, Wallpaper ea litsopa);

- Masela a botekgeniki a (Automotive, Airbags, Filters, li-ducts tse sa senyeheng