- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Chinese (Simplified)

- Chinese Traditional

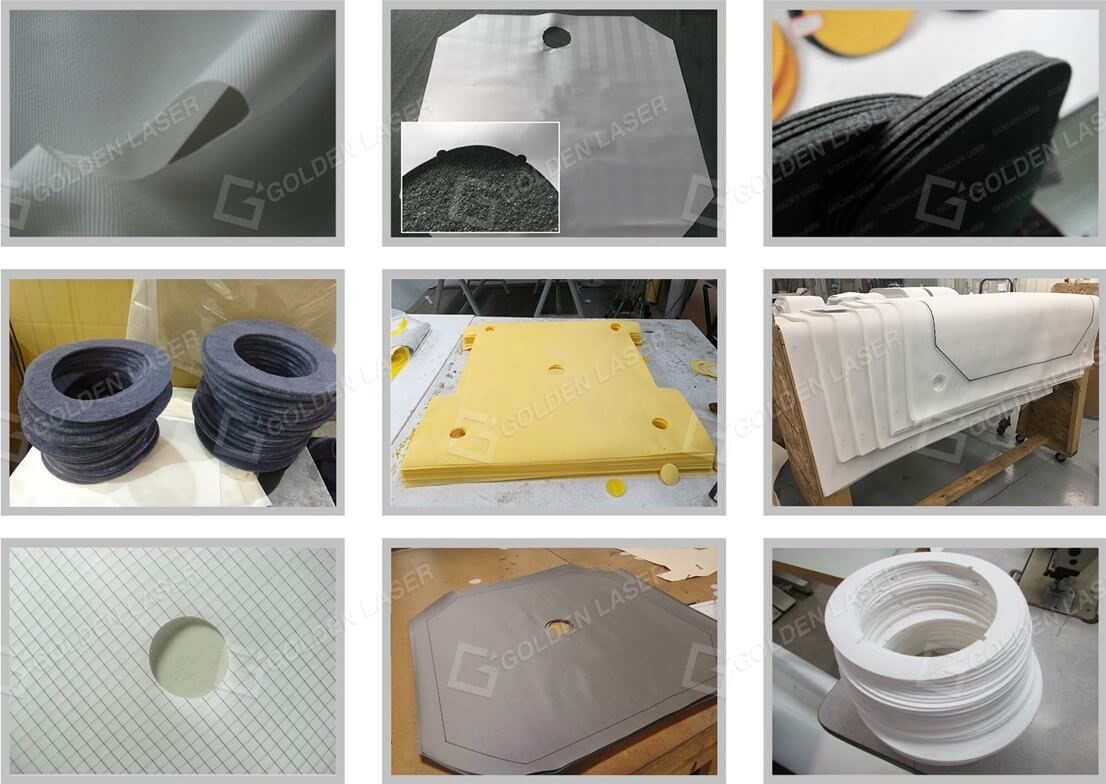

Laser la ho kuta laser la mecha ea filter

Kenyelletso ea indasteri ea boithabiso

E le tšireletso ea bohlokoa ea tikoloho le ts'ebetso ea taolo ea polokeho,Phetetsoe sebelisoa haholo masimong a mangata, karohano e tiileng ea khase, karohano e tiileng ea metsi, e tiileng - e tiileng le ea ho itlhoekisa moeeng le ho itlhoekisa moeeng. Likopo tse khethehileng li kenyelletsa kalafo ea khase e senyehileng ea lisebelisoa, limela tsa moea, tsa moea oa makoloi, tsa ho senyeha ha Likoloi tsa likoloi tsa likoloi.

Hajoale,Lisebelisoa tsa filtharaNa haholo-holo fiber ea fiber, masela a lohiloeng. Ka ho khetheha, thepa ea fiber e bohlokoa haholo-holo likhoele tse halikiloeng tse kang Commen, Viwnproplene, Seramante, le Filypud le Fiber, Setaele

Ka keketseho e tsoelang pele ea masimo a kopo ea kopo, lisebelisoa tse ncha tsa filthara li lula li hlaha, 'meLihlahisoa tsa FilrationLesela la khatiso ea filthara, lesela la lerole, mokotla oa sefahleho, finter, lifilimi, filthara, filthara ea filthara.

Goldhleser e fana ka li-cune tsaser li-cuts tsa masela a theknoloji

Foromo e kholo ea CO2 Laser Cutting mochinie loketse ho cheka sets'oants'o sa ho hloka phepelo e makatsang ka lebaka la ts'ebetso e seng ea puisano le mokhoa o hlakileng o fumanoeng ke laser. Ntle le moo, moralo oa mocheso oa futhumatsang o tiisa hore mekhahlelo e sehiloeng e tiisoa ka boeona ha e fokotsa masela a mahlale. Ho tloha ha laser cut lesela la filter le se nang bobebe, ho latela mosebetsi o latelang ho ba bonolo.

Khatiso e sehiloeng ea Khase e na le melemo efe ea ho roba mecha ea mecha ea filter?

Laser e sentse e se e le mokhoa oa indasteri ea filthara

Metsoako e nepahetseng ea lesela e ka etsoa ka mananeo a CAD mme a fapanyetsana likhoele tsa rona tsa CO2 Laser. U netefalitsoe hore ho tla tseba ho eketsehileng, lebelo le ho hlaka ka boleng ba mesebetsi ea khale ea khale.

Likopo tsa indasteri ea filthara

• Mabokose a pokello ea lerōle la mokotla / Fantration Clotts Cloth / Indasteri ea Filter Carridge / Filsh Fabric

• Flotara ea moea / fluid / Froptation Filtration / Li-lesela la mahlale

• Ho omisa / ho omella, ho hlahlojoa / ho hlahlobisisa

• Ho fifala ha metsi / ho fitlice

• Mining Fittation / oli le filtration / Folop le Foulp le lipalesa tsa pampiri

• Lihlahisoa tsa moea o sa senyeheng

Lisebelisoa tsa filthara tse loketseng laser

Filter tab, khalase e se nang lesela, pampiri e seng ea lohiloeng, e leng folypropylene, polypropylene, polyproplene, polyproplene, polyproplene, polyproplene, polyproplene, polyproplene, polyproplene, polyproplene, polyproplene, polyproplene

Re khothaletsa metjeko ea CO2 Laser bakeng sa ho cheka lesela la filter

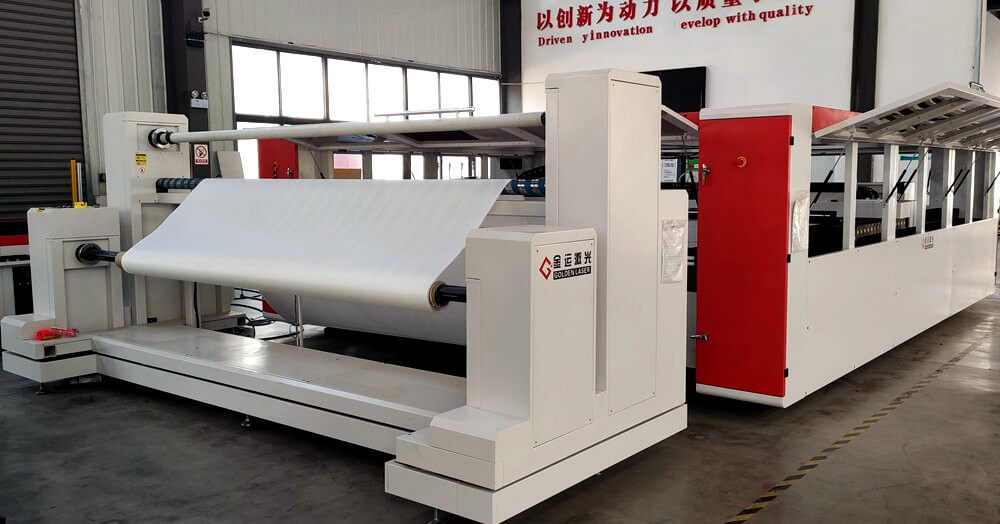

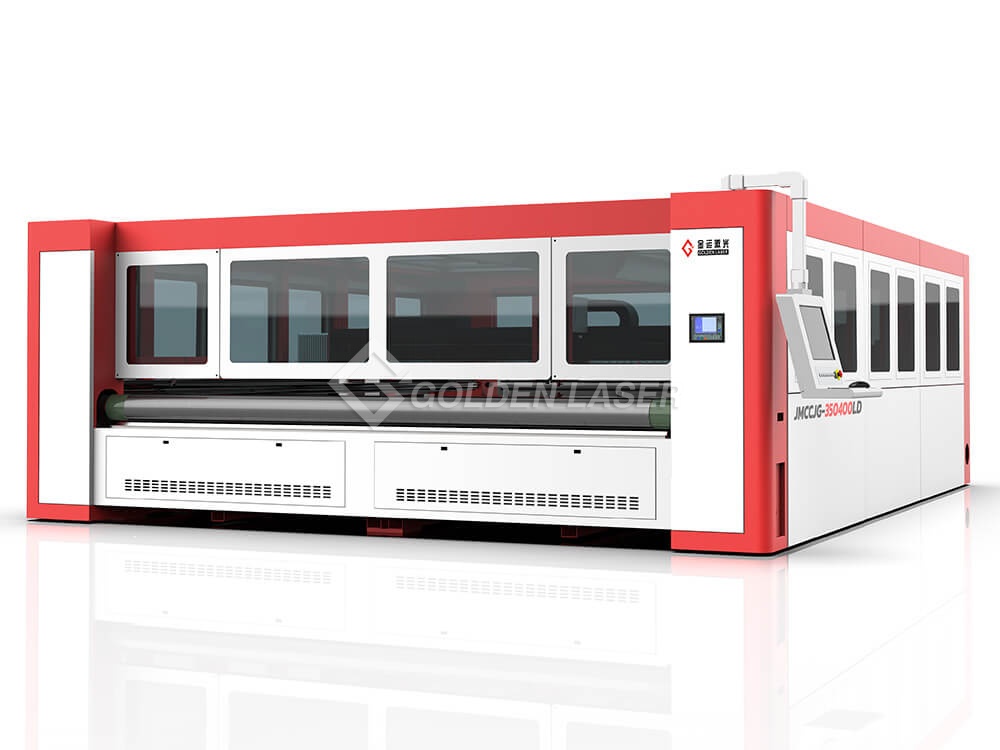

Goldhleser JMC Series e phahameng haholo

Mabaka a mane

Ho khetha ho tsamaea ha rmc letory co2 Laser mochini o sehiloeng

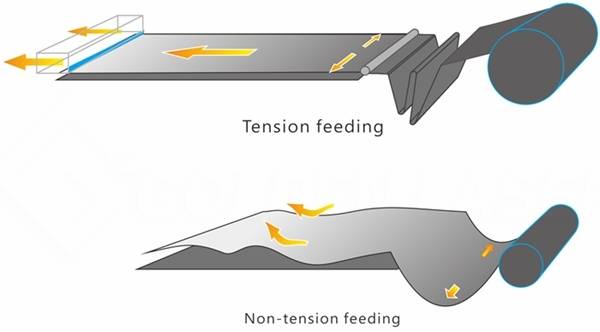

1.Ho fepa ho fepa bohloko

Ha ho na lijo tsa tsitsipano li tla nolofalletsa ho khopamisa mefuta e fapaneng ea ts'ebetso ea ho fepa, ho fella ka moea o tloaelehileng oa ho lokisa e ngata;Seteishene sa TlokotsiKa lebaka la ho se khone ho tsitsipanya mahlakore ka bobeli a ntho e iketsang ka boeona, ka boeona e tla ba khalemelo e phethahetseng, e tla ba khalemelo e phethahetseng le ho e lokisa.

2.Ho itšeha ka lebelo le phahameng

Sisteme ea Rack le Pinionee na le tube e phahameng ea laser2lebelo le potlakileng.

3.Sisteme ea mofuta o iketsang

Sistimi e ikemetseng ka botlalo. Ho fepa ka nama, ho kuta, ho hlophisa ka nako e le 'ngoe.

4.Libaka tse sebetsang li ka etsoa

2300mm × 2300mm (90.5 inch × 90.5 inch), 2500mmm), 3000mm × 118in Sebaka se seholo sa ho sebetsa se holimo ho 3200MM × 12000mmm (126IN × 472.4in)