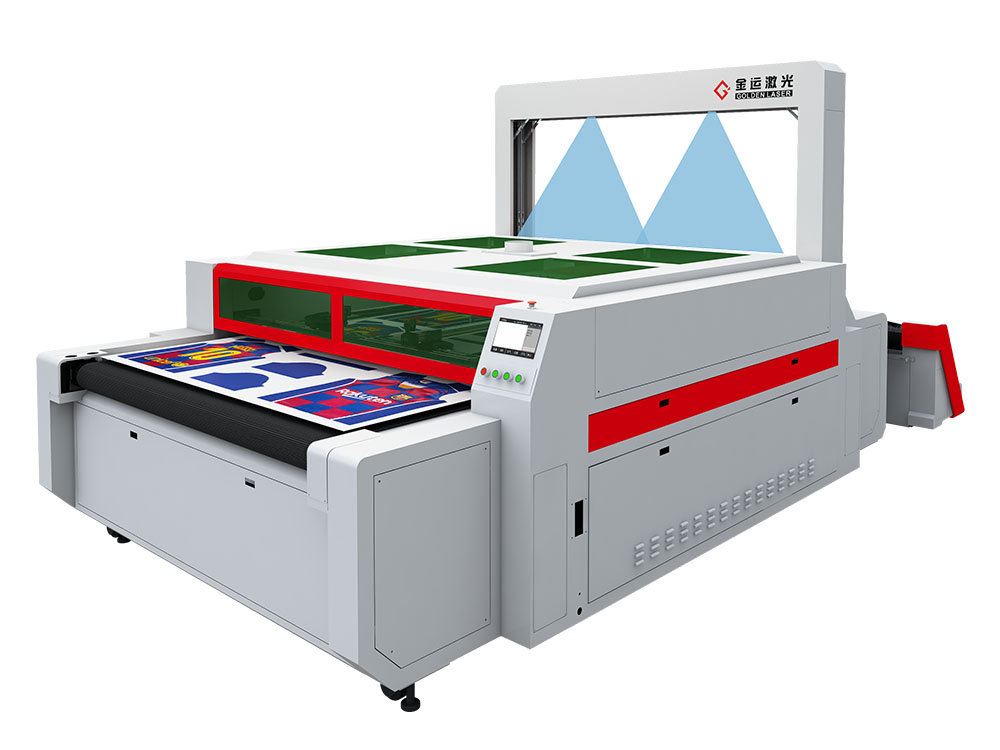

Dual Head Vision Scan Sublimation Fabric Laser Cutter

Model No.: CJGV-160120LD

Introduction:

Vision Laser is is ideal for cutting sublimated fabric of all shapes and sizes. Cameras scan the fabric, detect and recognize printed contour, or pick up on registration marks and cut the chosen designs with speed and accuracy. A conveyor and auto-feeder is used to keep cutting continuous, saving time and increasing production speed.

- Working area : 1600mm×1200mm (63"×47.2")

- Camera scanning area : 1600mm×800mm (63"×31.4")

- Collection area : 1600mm×600mm (63"×23.6")

- Laser power : 150W, 300W

- Cutting speed : 0-800 mm/s

• While the roll of sublimated fabric is being fed onto the conveyor table, the vision system performs a fast scan on the fly of the printed contour and automatically creates a vector file. It optimizes the use of printed fabrics as the vision scanning technology scans the entire bed within 5 seconds before starting the cutting process.

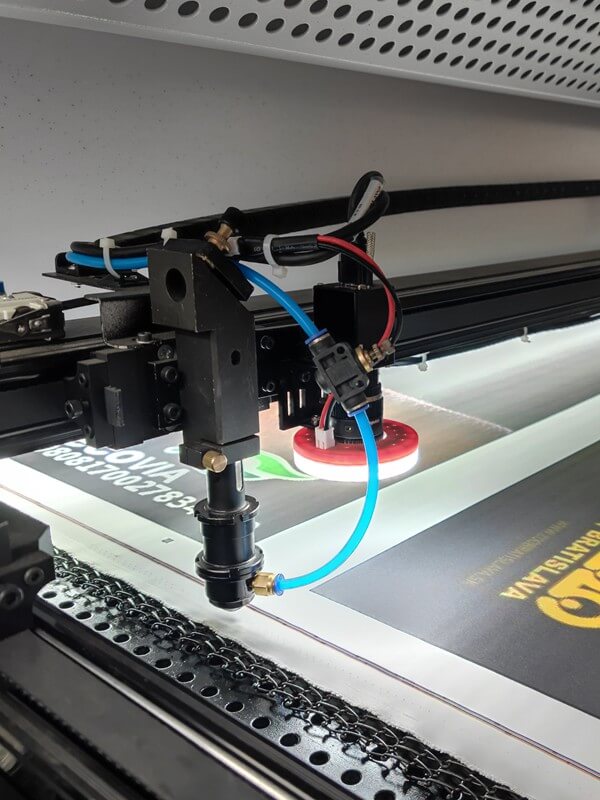

• Alternatively, the registration marks can be accurately read by the camera, allowing intelligent algorithm to compensate for any distortions or stretches that may occur in unstable rolls of textile.

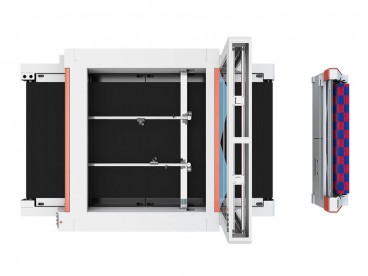

• Independent dual laser heads cut their respective allocated areas simultaneously, high processing efficiency.

• In addition to the 2 overhead industrial cameras, a CCD camera and a registration camera can be mounted next to each of the two laser heads for precise recognition and cutting of small graphics such as embroidered labels, woven labels, dye-sub letters/numbers/logos, etc.

• A conveyor bed and auto-feeder are used to keep cutting continuous, saving time and increasing production speed.

• Extension table is conducive to pick up the cut pieces.

Exclusive Features

Specifications

Main Technical Parameters of the CJGV160130LD Vision Laser Cutter

| Working area | 1600mm×1200mm (63"×47.2") |

| Camera scanning area | 1600mm×800mm (63"×31.4") |

| Collection area | 1600mm×500mm (63"×19.6") |

| Working table | Conveyor working table |

| Laser type | CO2 glass laser / CO2 RF metal laser |

| Laser power | 150W |

| Cutting speed | 0-800 mm/s |

| Positioning accuracy | ±0.1mm |

| Motion system | Servo motor |

| Camera | Industrial cameras |

| Software | Goldenlaser CAD Scanning Software Package |

| Options | Auto feeder, red dot, CCD camera for registration |

WORK MODE 1 → Scan on the Fly

<< Step 1

Loading the dye-sublimated roll fabrics to the conveyor working table of laser cutter with auto-feeder.

Step 2

HD Cameras scan the fabrics, detect and recognize the printed contour, and send the information to laser cutter. >>

<< Step 3

Set the cutting parameters. Press "start" button on laser cutter. Then the laser cutting machine will do cutting automatically.

Step 4 Laser cutting and repeat the entire process. >>

Printing requirement - The printed outline and materials background have big color difference, distance not less than 5mm between the contours. Only the outer contour can be cut, the inside nested graphics cannot be cut.

WORK MODE 2 → SCAN PRINT MARKS

Application

- For soft materials easy to distort, curl, extended

- For complicated pattern, nesting pattern inside the outline and high precision cutting requirement

Requirement

Need 1:1 original printed graphics file. Graphics format: *.jpg, *.bmp, or *.png

Sublimation Fabrics Laser Cutting Sample - Before Laser Cutting VS. After Laser Cutting

Before Cutting

After Cutting

Goldenlaser's Vision Scanning Laser System solved the problem of position deviation, rotation angle, and elastic stretching during the sportswear cutting process.

Vision Laser Cutting Samples

VISION LASER CUT - advanced laser cutting for dye sublimation printed fabrics and textiles

Watch Vision Laser in Action

Vision Scan On-the-fly Laser Cutting for Dye-sublimation Printed Sportswear and Masks

VISION LASER CUT - advanced laser cutting machine for dye sublimation, printed fabrics and textiles

High speed scanning on-the-fly, instant vectorization, laser sealed edges. Just press and go!

Technical Parameter of the Vision Laser Cutter CJGV160120LD

| Working area | 1600mm x 1200mm (63” x 47.2”) |

| Camera scanning area | 1600mm x 800mm (63” x 31.4”) |

| Collection area | 1600mm x 600mm (63” x23.6”) |

| Working table | Conveyor working table |

| Vision system | Industrial cameras |

| Laser power | 150W, 300W |

| Laser tube | CO2 glass laser tube / CO2 RF metal laser tube |

| Motors | Servo motors |

| Cutting speed | 0-800 mm/s |

| Cooling system | Constant temperature water chiller |

| Exhaust system | 1.1KW Exhaust fan x 2, 550W Exhaust fan x1 |

| Power supply | 220V / 50Hz or 60Hz / Single phase |

| Electrical standard | CE / FDA / CSA |

| Power consumption | 9KW |

| Software | GoldenLaser Scanning Software Package |

| Dimensions | L 3590mm x W 2205mm x H 2200mm (11.8′ x 7.2′ x 7.2’) |

| Other options | Auto feeder, red dot, CCD camera for registration |

Golden Laser – Full Range of Vision Laser Cutting Systems

Ⅰ High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160100LD | 1600mm×1000mm (63”×39.3”) |

| CJGV-160120LD | 1600mm×1200mm (63”×47.2”) |

| CJGV-180100LD | 1800mm×1000mm (70.8”×39.3”) |

| CJGV-180120LD | 1800mm×1200mm (70.8”×47.2”) |

| CJGV-160200LD | 1600mm×2000mm (63″×78.7″) |

Ⅱ High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ⅲ Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Ⅳ Smart Vision (Dual Head) Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

Ⅴ CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

Laser Cutting Sublimated Fabric Samples

Laser cutting sublimated apparel fabric with clean and sealed edges

Laser cutting hockey jerseys

Application

→ Sportswear Jerseys (basketball jersey, football jersey, baseball jersey, ice hockey jersey)

→ Cycling apparel

→ Active wear, leggings, yoga wear, dance wear

→ Swimwear, bikinis

As a professional provider of laser application solutions, GOLDEN LASER is constantly innovating in high-speed vision scanning laser cutting system, sportswear high-speed perforating laser system, high-precision vision recognition laser cutting system, and integrating operating systems for digital printing industry, has been committed to helping customers create greater value.

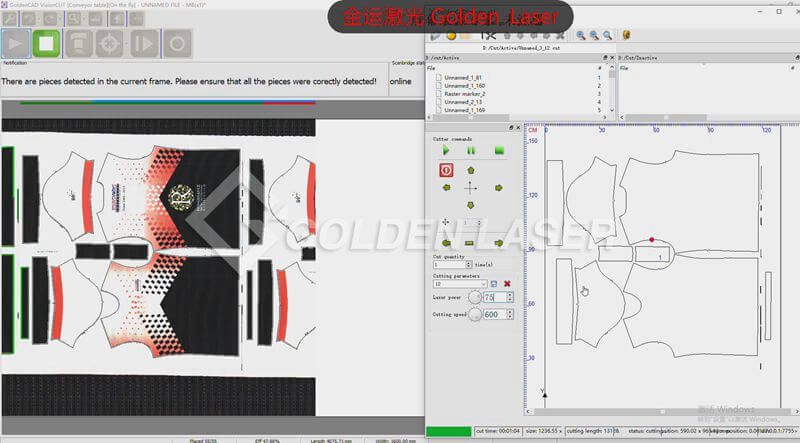

GOLDEN CAD VISION SCANNING SYSTEM

GOLDEN CAD vision scanning system aims to realize the seamless integration and highly automation of digital printing process. The design, grading, nesting and other processes are integrated into GOLDEN CAD vision scanning system in the most cost-effective way and directly outputs the EPS and PDF file formats to the printer. Finally, accurate laser cutting of digital printed materials is accomplished thanks to the efficient automated vision scanning system.

1. DESIGN

Grading and modifying design graphics with GOLDEN Pattern Designer Software.

2. Pre-Production

Nesting the designed graphics with AUTO MARKER software to output PDF format for printing.

3. Printing

Sending the PDF files to the printer for printing and then dye sublimation to textile.

4. Laser Cutting

Vision laser cutting machine scans the sublimation printed fabric from roll, and the camera detects the printed contour and sends the information to the computer and the laser cutter, then laser cuts automatically and continuously.

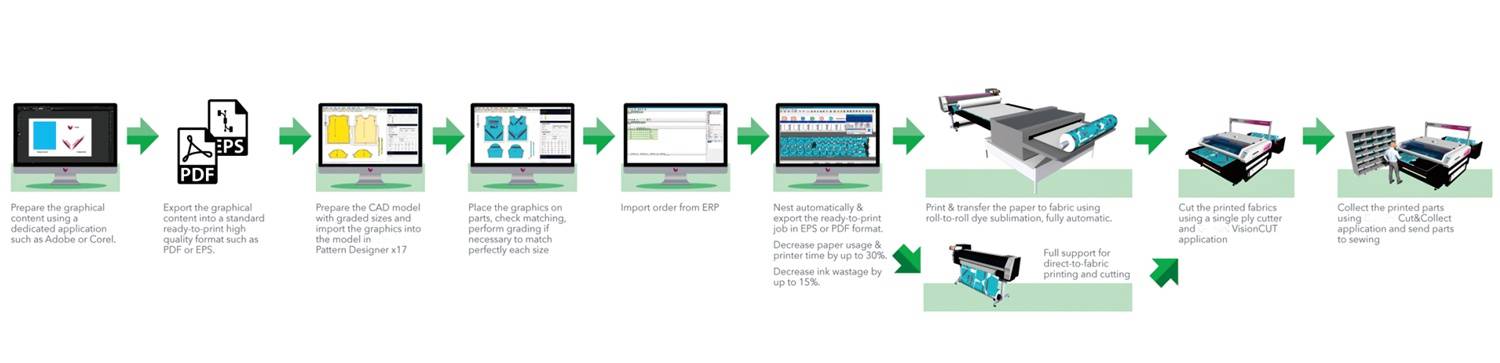

Traditional Working Flow for Sportswear Production

How GOLDEN CAD Vision Scanning System Simplifies the Production Process of Sportswear?  WHAT ARE THE BENEFITS OF GOLDEN CAD VISION SCANNING SYSTEM?

WHAT ARE THE BENEFITS OF GOLDEN CAD VISION SCANNING SYSTEM?

• Simplify the process

• Save 60% labor cost

• Save 35% consumable – transfer paper / print time / materials

• Save 10% ink consumption

• Save space, save storage cost

• Decrease defect rate and ensure product quality