Sublimation Printed Fabric Laser Cutting Machine for Sports Jerseys Apparel

Model No.: CJGV-190130LD

Introduction:

VISIONLASER CUTTING SYSTEM – √ Auto feeding √ Flying scan √ High speed √ Detecting and recognizing printed contour of sublimated roll of fabric. Cutting a variety of materials, like polyester, cotton, polymide, PVC, vinyl, etc. Laser cutting speed reaches up to 600 mm/s. Automated production process with conveyor belts and auto-feeding system.

Sublimation Printed Fabric Laser Cutting Machine

VISION LASER CUTTING SYSTEM – √ Auto feeding √ Flying scan √ High speed √ Scan ( detecting and recognizing) a sublimated roll of fabric and take into account any shrinkage or distortion that may occur during the sublimation process and accurately cut out any designs.

Why Vision Laser Cutting Printed Fabric?

● Versatile. Cut a variety of materials, like polyester, cotton, microfiber, polymide, PVC, vinyl, etc.

● High Speed. Laser cutting speed reaches up to 600 mm/s. Automated production process with conveyor and auto-feeding system.

● Precise. High precision, smooth cutting edge, no fraying, no need to rework on cutting edges.

● Clean. Non-contact laser process. No need to glue paper onto textile, avoiding manual pollution during scissors cutting process.

● High flexibility. Cut any kinds of shapes simultaneously.

● Save time, save materials, and save labor cost.

Digital Printing Sublimation Fabric Laser Cutting Solution

● Large format flying recognition. 5 seconds to identify 1.6m x 3m. When conveyor belt feeding, the camera can quickly identify printed fabric, or stripes, plaids fabric in real-time and then the cutting information transmitted to cutting machine. After cutting an entire format, processing will repeat the same process.

● Good at dealing with complex graphics. Specializes in the processing of elastic material. Edge clean, soft, tidy, automatic sealing edge, high accuracy.

● One machine can process 500-800 sets of clothing per day. The whole process without human intervention. With auto feeding system, scanning contour extraction, feeding and cutting finished at one time.

|

Model No. |

CJGV-190130LD Vision Laser Cutter |

|

|

Laser Type |

Co2 glass laser |

Co2 RF metal laser |

|

Laser Power |

150W |

150W |

|

Working Area |

1900mmX1300mm (74”×51”) |

|

|

Working Table |

Conveyor working table |

|

|

Working Speed |

0-600 mm/s |

|

|

Positioning Accuracy |

±0.1mm |

|

|

Motion System |

Offline servo motor control system, LCD screen |

|

|

Cooling System |

Constant temperature water chiller |

|

|

Power Supply |

AC220V±5% 50/60Hz |

|

|

Format Supported |

AI, BMP, PLT, DXF, DST, etc. |

|

|

Standard Collocation |

1 sets of top exhaust fan 550W, 2 sets of bottom exhaust fans 1100W, 2 German cameras |

|

|

Optional Collocation |

Automatic feeding system |

|

|

Environmental Requirement |

Temperature Range: 10—35℃ Humidity Range: 40—85% the use environment of no inflammable, explosive, strong magnetic, strong earthquake |

|

|

*** Note: As products are constantly updated, please contact us for the latest specifications. *** |

||

| GOLDEN LASER - Vision Laser Cutting Machine | Model NO. | Working Area |

| CJGV-160130LD | 1600mm×1300mm (63” ×51”) | |

| CJGV-160200LD | 1600mm×2000mm (63” ×78”) | |

| CJGV-180130LD | 1800mm×1300mm (70” ×51”) | |

| CJGV-190130LD | 1900mm×1300mm (74” ×51”) | |

| CJGV-320400LD | 3200mm×4000mm (126” ×157”) |

Application

→ Sportswear Jerseys (basketball jersey, football jersey, baseball jersey, ice hockey jersey)

→ Cycling apparel

→ Active wear, leggings, yoga wear, dance wear

→ Swimwear, bikinis

1. On the fly – large format recognition continuous cutting

This function is for patterned fabric precisely positioning and cutting. For example, through digital printing, various graphics printed on fabric. In the subsequent of positioning and cutting, material information extracted by the high-speed industrial camera (CCD), software smart identification closed outer contour graphics, then automatically generates the cutting path and finish cutting. Without the need for human intervention, it can achieve continuous recognition cutting of the entire roll printed fabrics. I.e. by large format visual recognition system, the software automatically recognize the contour pattern of the garment, and then automatic contour cutting graphics, thus ensuring accurate cutting of the fabric. Advantage of contour detection

- No required the original graphics files

- Directly detect roll printed fabrics

- Automatic without manual intervention

- Identification within 5 seconds on the whole cutting area

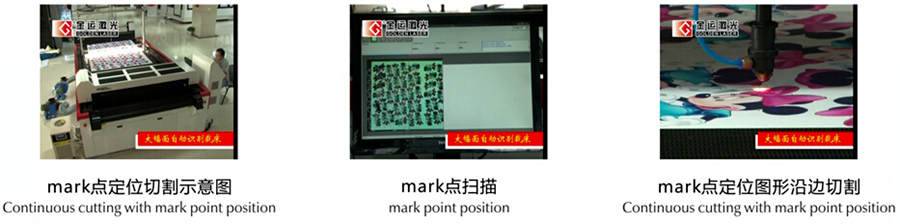

2. Printed Marks Cutting

This cutting technology is applicable to a variety of patterns and labels precision cutting. Especially suitable for automatic continuous printing clothing contour cutting. Marker point positioning cutting no pattern size or shape restrictions. Its positioning is only associated with two Marker points. After two Marker points to identify the location, entire format graphics can be precisely cut. (Note: arrangement rules must be the same for each format of the graphic. Automatic feeding continuous cutting, to be equipped with feeding system.) Advantage of printed marks detection

- High precision

- Unlimited for the distance between printed pattern

- Unlimited for printing design and background color

- Compensation of processing material deformation

3. Strips and Plaids Cutting

CCD camera, which is installed in the rear of the cutting bed, can recognize materials information such as stripes or plaids according to color contrast. The nesting system can perform automatic nesting according to the identified graphical information and cut pieces requirement. And can automatically adjust the pieces angle to avoid stripes or plaids distortion on the feeding process. After nesting, the projector would emit red light to mark the cutting lines on materials for calibration.

4. Square Cutting

If you only need to cut square and rectangle, if you don’t have high requirement about cutting precision, you can choose below system. Work flow: small camera detect the printing marks and then laser cut the square/rectangle.